Factory logistics simulation experimental apparatus

A technology for simulating experimental equipment and logistics, applied in teaching models, educational tools, instruments, etc., can solve the problems of poor fidelity of logistics sand table, etc., and achieve the effect of solving poor fidelity, high fidelity and good experimental effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

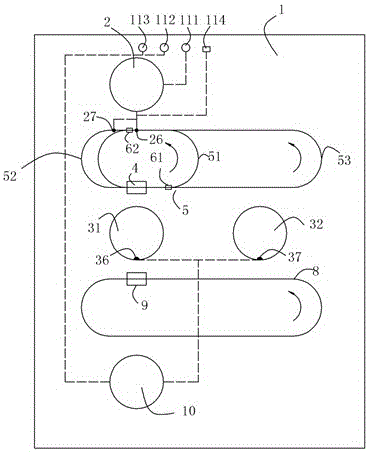

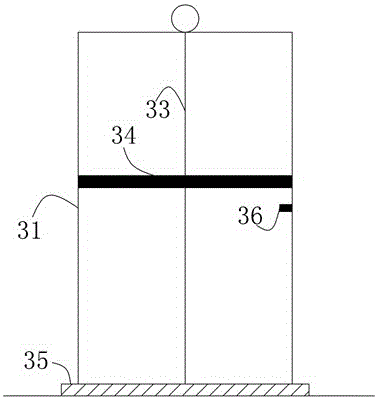

[0031] The embodiment of factory logistics simulation experiment device among the present invention: as Figure 1 to Figure 3 As shown, the experimental device includes a sand table 1, and a raw material bin 2, two intermediate bins and a finished product bin 10 are sequentially arranged on the surface of the sand table 1 from front to back.

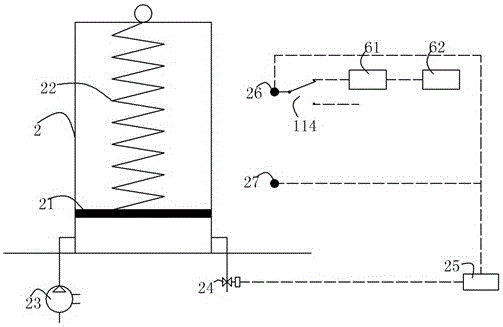

[0032] The raw material bin 2 is provided with a first piston 21 that can slide up and down. A first return spring 22 for pushing the first piston 21 is connected above the first piston 21. A piston chamber below the first piston 21 is connected with a The first air source 23 for continuous air supply and the first exhaust valve 24 for controlling exhaust, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com