Waterproof coiled material replacing device facilitating automatic replacement

A waterproofing membrane, automatic replacement technology, applied in transportation and packaging, transportation of filamentous materials, tools for roof engineering, etc., can solve the problems of low practicability and low reliability, achieve simple operation, improve intelligence , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

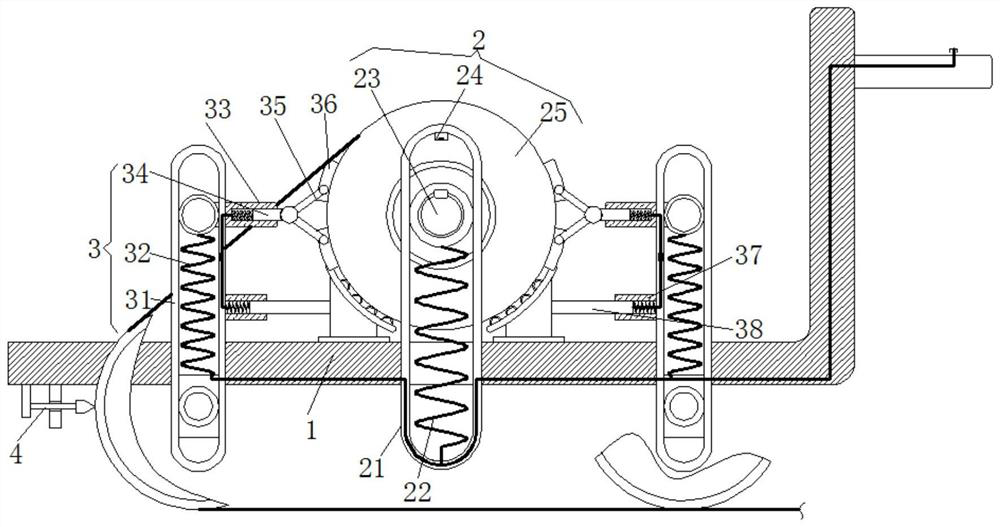

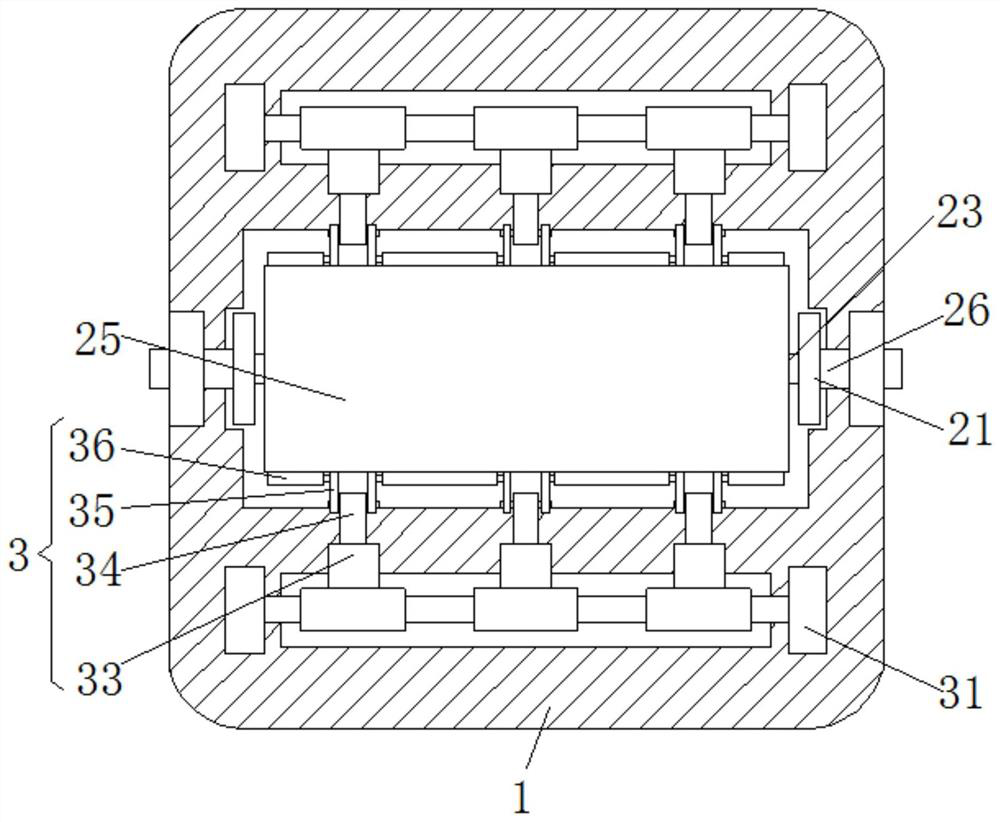

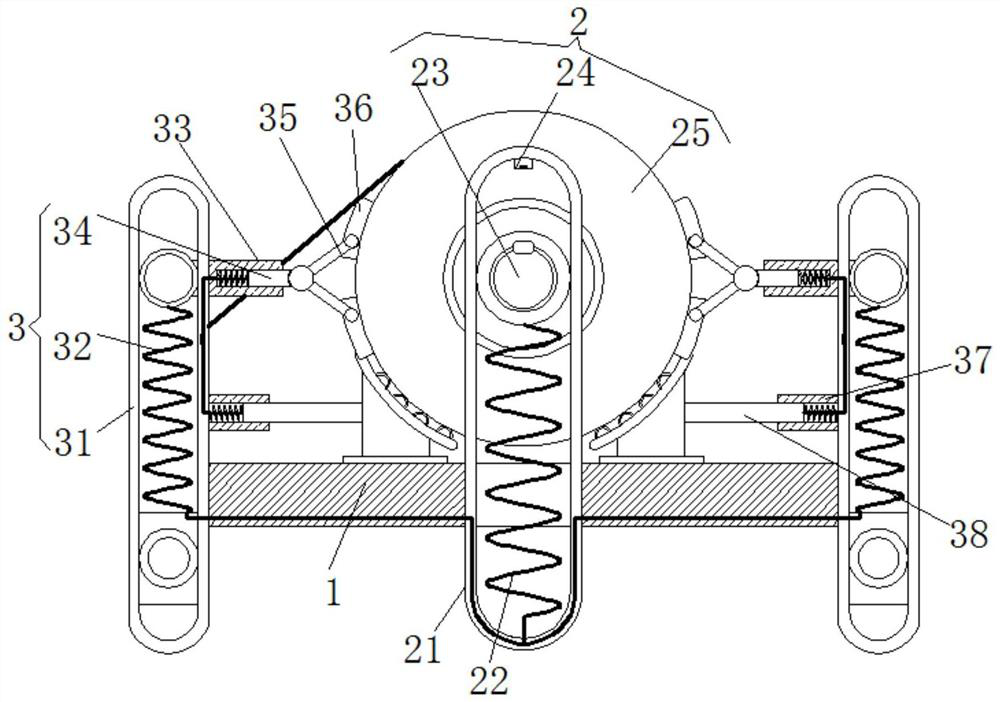

[0025] see Figure 1-4 , a waterproof membrane replacement device that is convenient for automatic replacement, including a fixing mechanism 3, the fixing mechanism 3 includes a first bracket 31, the inside of the first bracket 31 is fixedly connected with a energized coil-32, and the top of the energized coil-32 The first chute 33 is fixedly connected, the inside of the first chute 33 is slidably connected with a first slider 34, the top of the first slider 34 is rotatably connected with a first connecting rod 35, and the top of the first connecting rod 35 is rotatably connected There is a pressing plate 36, the side of the first bracket 31 is fixedly connected with a second chute 37, the inside of the second chute 37 is slidably connected with a second slider 38, and one end of the second slider 38 is fixedly connected with a heating block 39, so , through electrical control, the energized solenoid coil one 32 shrinks downward, thereby placing the first rotating shaft 23 on ...

Embodiment 2

[0027] see Figure 1-4 , a waterproof membrane replacement device that is convenient for automatic replacement, including a fixing mechanism 3, the fixing mechanism 3 includes a first bracket 31, the inside of the first bracket 31 is fixedly connected with a energized coil-32, and the top of the energized coil-32 The first chute 33 is fixedly connected, the inside of the first chute 33 is slidably connected with a first slider 34, the top of the first slider 34 is rotatably connected with a first connecting rod 35, and the top of the first connecting rod 35 is rotatably connected There is a pressing plate 36, the side of the first bracket 31 is fixedly connected with a second chute 37, the inside of the second chute 37 is slidably connected with a second slider 38, and one end of the second slider 38 is fixedly connected with a heating block 39, so , through electrical control, the energized solenoid coil one 32 shrinks downward, thereby placing the first rotating shaft 23 on ...

Embodiment 3

[0029] see Figure 1-4 , a waterproof membrane replacement device that is convenient for automatic replacement, including a fixing mechanism 3, the fixing mechanism 3 includes a first bracket 31, the inside of the first bracket 31 is fixedly connected with a energized coil-32, and the top of the energized coil-32 The first chute 33 is fixedly connected, the inside of the first chute 33 is slidably connected with a first slider 34, the top of the first slider 34 is rotatably connected with a first connecting rod 35, and the top of the first connecting rod 35 is rotatably connected There is a pressing plate 36, the side of the first bracket 31 is fixedly connected with a second chute 37, the inside of the second chute 37 is slidably connected with a second slider 38, and one end of the second slider 38 is fixedly connected with a heating block 39, so , through electrical control, the energized solenoid coil one 32 shrinks downward, thereby placing the first rotating shaft 23 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com