Anti-precipitation device for foam extinguishing agent

A foam fire extinguishing agent and anti-precipitation technology, which is applied to mixers with rotating stirring devices, dissolvers, mixers, etc., can solve the problems of poor foam fire extinguishing agent precipitation and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

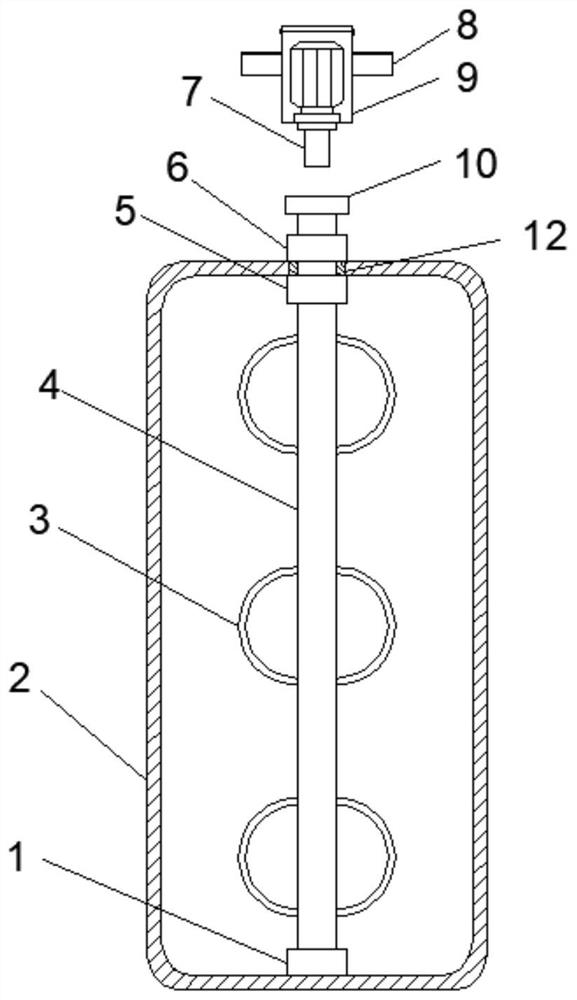

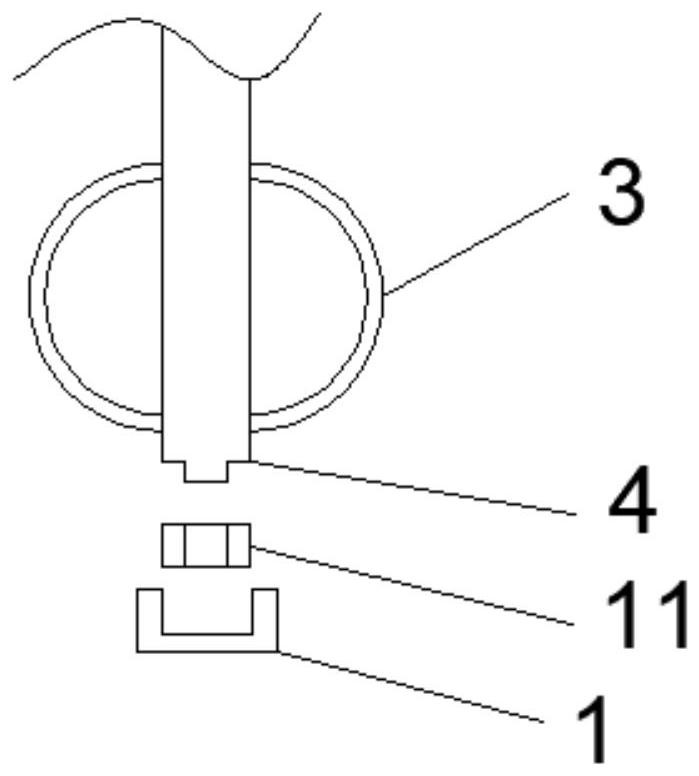

[0018] see Figure 1-4 , the present invention provides a technical solution: an anti-sedimentation device for foam fire extinguishing agent, please refer to figure 1 Specifically, there is a tank body 2, the bottom surface of the tank body 2 is provided with a fixed block 1, and the fixed block 1 is fixedly connected with the tank body 2, the upper end surface of the fixed block 1 is provided with a stirring rod 4, and the stirring rod 4 is movable with the fixed block 1 The connection can support the stirring rod 4 when stirring, and can prevent the rotation of the stirring plate 4 from causing damage to the bottom end surface of the inner cavity of the tank body 2.

[0019] see figure 1 , the outer wall of the stirring rod 4 is provided with six sets of stirring rings 3, and the stirring rings 3 and the stirring rod 4 are detachably connected, and each group of stirring rings 3 is arranged oppositely, and the stirring rings 3 are arranged on the outer wall of the stirring ...

Embodiment 2

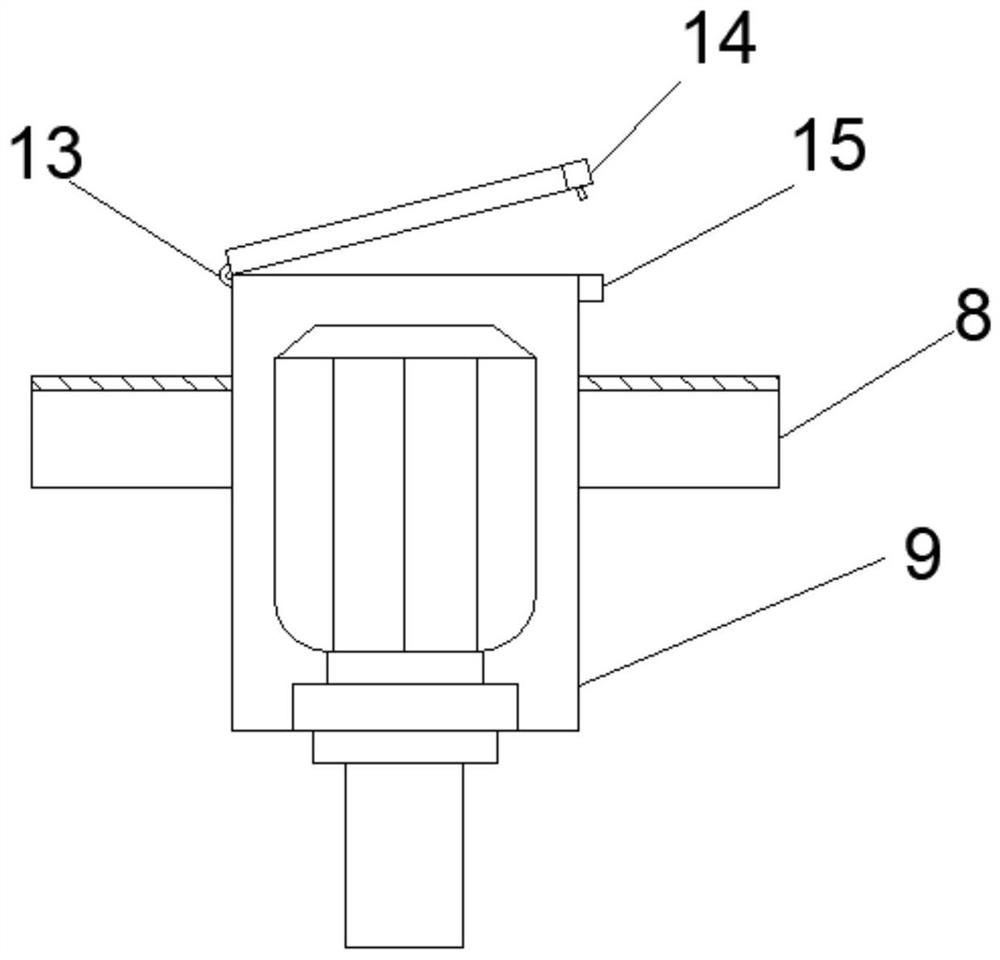

[0026] Such as image 3 As shown, the difference from the previous embodiment is that the top surface of the motor housing 9 is provided with a rectangular opening 2, a maintenance door is provided at the rectangular opening 2, and a movable hinge 13 is provided on the left side of the maintenance door. 13 One end that is not connected with the maintenance door is movably connected with the motor housing 9, the left side of the maintenance door is provided with a buckle 14, and the buckle 14 is detachably connected with the maintenance door, the right side of the motor housing 9 is connected to the The corresponding position of the buckle 14 is provided with a draw-in groove 15 matching the buckle 14, and the draw-in groove 15 is detachably connected with the motor housing 9, which can be more convenient for people's work when repairing and maintaining the motor.

[0027] Such as image 3 As shown, the top surface of the handle 8 at both ends of the motor housing 9 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com