Bearing convenient to mount

A bearing and mounting block technology, applied in the direction of bearing components, shafts and bearings, rigid brackets of bearing components, etc., can solve the problems of radial size, large vibration and noise, reduce friction coefficient, difficult bearing maintenance, etc., to improve the connection. speed, improved usability, improved connection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

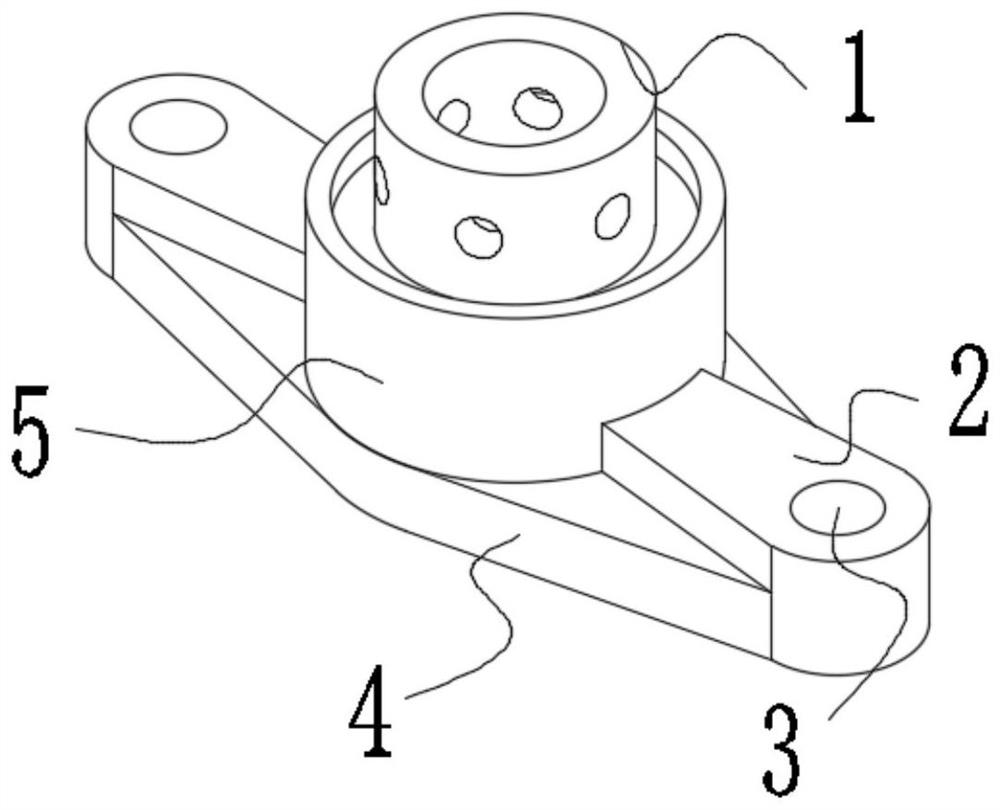

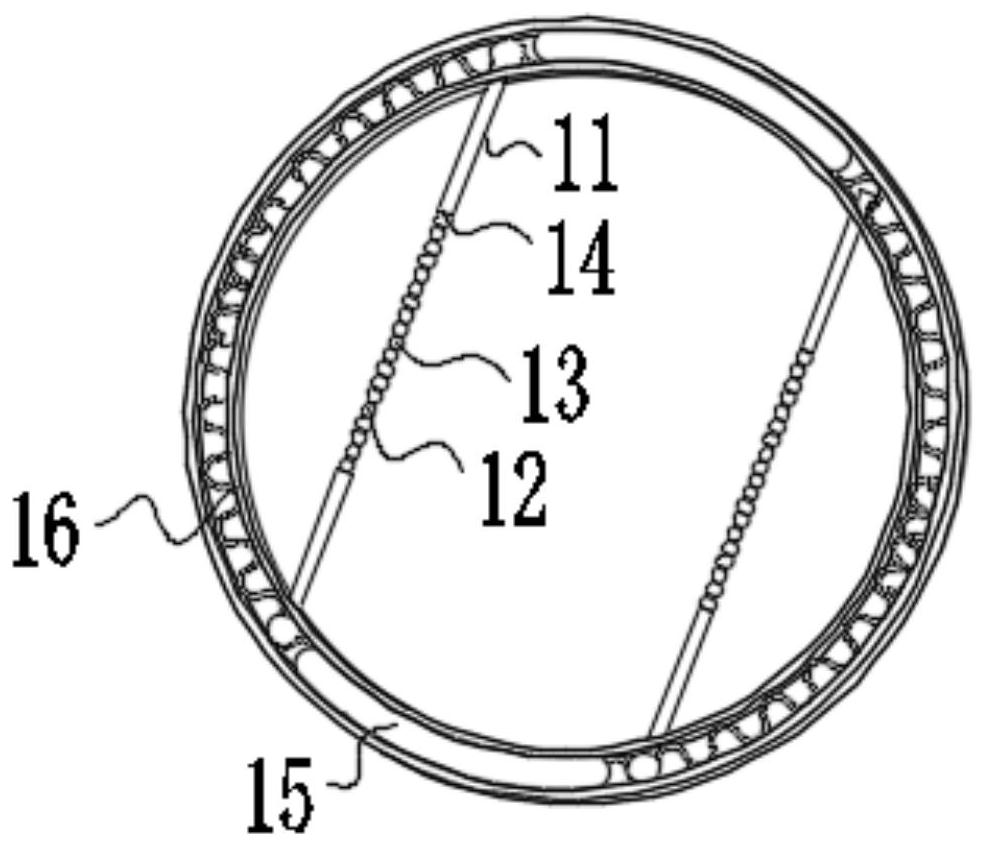

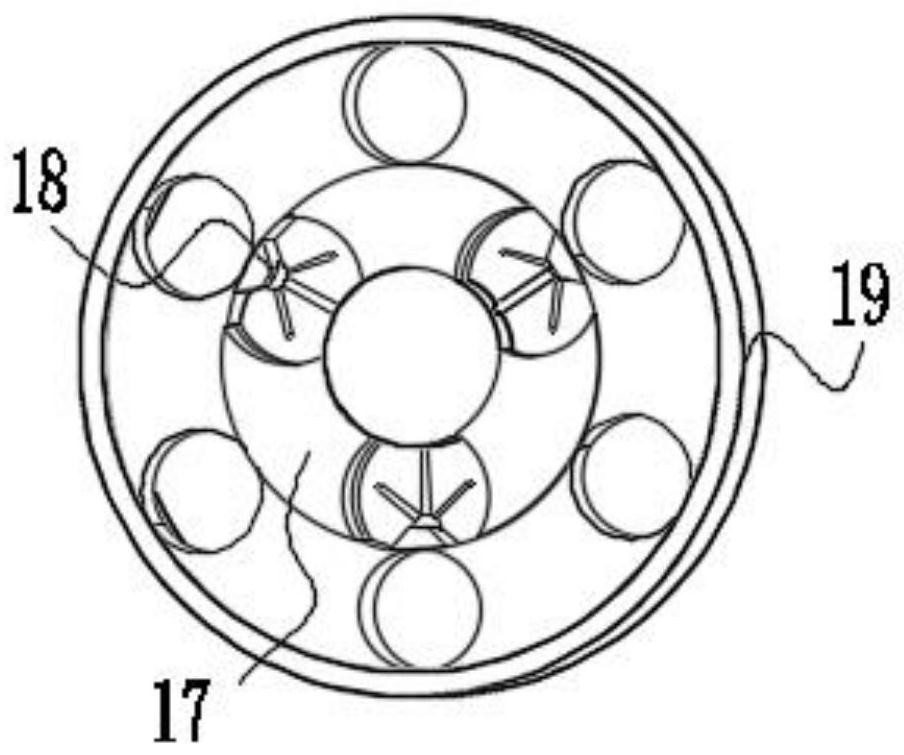

[0024] use Figure 1-Figure 7 An easy-to-mount bearing according to an embodiment of the present invention will be described as follows.

[0025] Such as Figure 1-Figure 7 As shown, an easy-to-install bearing of the present invention includes a connecting sleeve 1; The two ends of the mounting block 2 are symmetrically arranged, and the right end of the fixing column 5 is fixedly connected with the left end of the mounting block 2, the axis of the mounting block 2 is provided with a mounting hole 3, and the bottom of the fixing column 5 is provided with a bottom plate 4, and fixed The bottom of the column 5 is fixedly connected with the top of the bottom plate 4, and the purpose of setting the fixed column 5 is to improve the stability of the bearing.

[0026] The top of the connecting sleeve 1 is provided with a contraction ring 15, and the interior of the contraction ring 15 is symmetrically provided with a contraction spring 16, and the inner wall of the contraction ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com