Concrete mixture workability informatization intelligent regulation and control method

A technology for concrete and mixture, applied in the field of concrete, can solve the problems of the concrete mixture being difficult to meet the construction requirements, the loss of fluidity over time, and the blockage and explosion of pipes, so as to promote the leap-forward development of the industry and have broad prospects for market promotion. , to meet the effect of construction needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

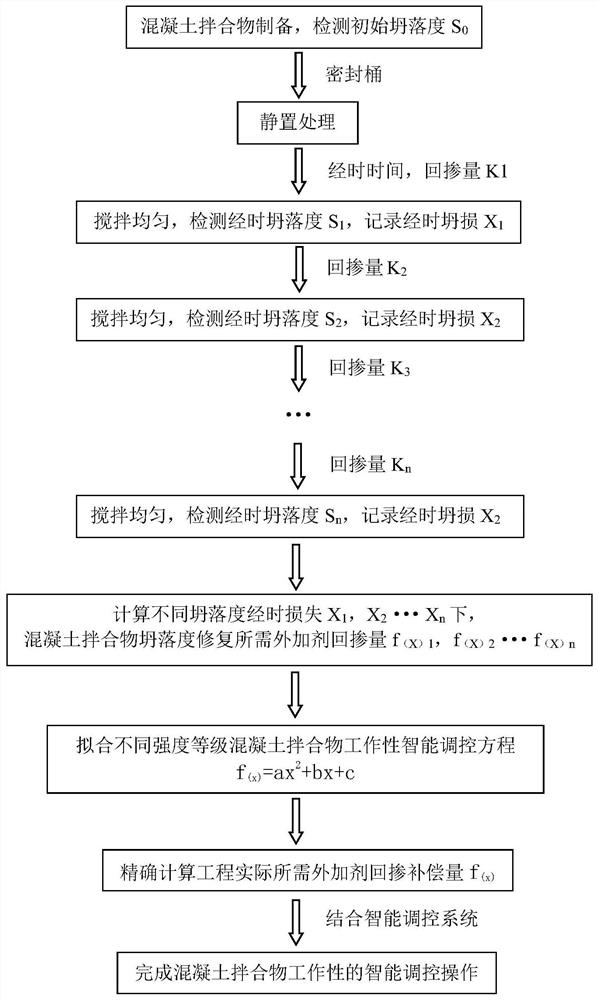

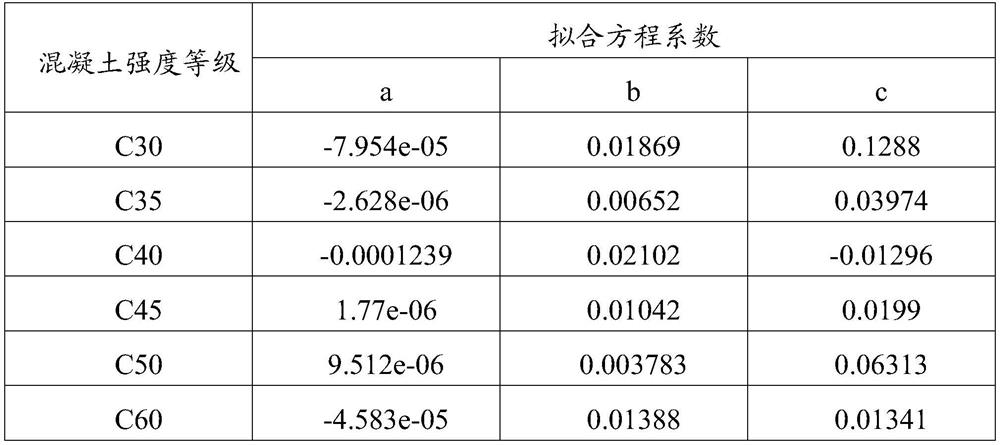

[0032] This embodiment provides a concrete mixture workability information intelligent control method, the method includes the following steps:

[0033] (1) Prepare concrete mixtures of different strength grades (such as C30-C60) under the same proportioning conditions corresponding to the actual project, and test its initial slump S 0 ;

[0034] (2) Put the prepared concrete mixture of different strength grades (such as C30-C60) in a sealed bucket, and let it stand for a period of time (such as 3h);

[0035] (3) When the elapsed time is reached, re-stir the concrete mixture in the sealed bucket evenly, and record the admixture amount K 1 =0, detect its slump S over time 1 , record the value of slump loss over time X 1 = S 0 -S 1 ;

[0036] (4) The mass of backmixing into the concrete mixture is K 2 admixture, stir evenly, and check its slump S 2 , record the value of slump loss over time X 2 = S 0 -S 2 ;

[0037] (5) Repeat step (4) to record the accumulative remi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com