Electromagnetic switch device with adjustable force

An electromagnetic switch and force adjustment technology, applied in electric switches, power devices inside switches, electromagnetic relays, etc., can solve the problems of reduced service life, contact wear, poor experience, etc., and achieve the effect of prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

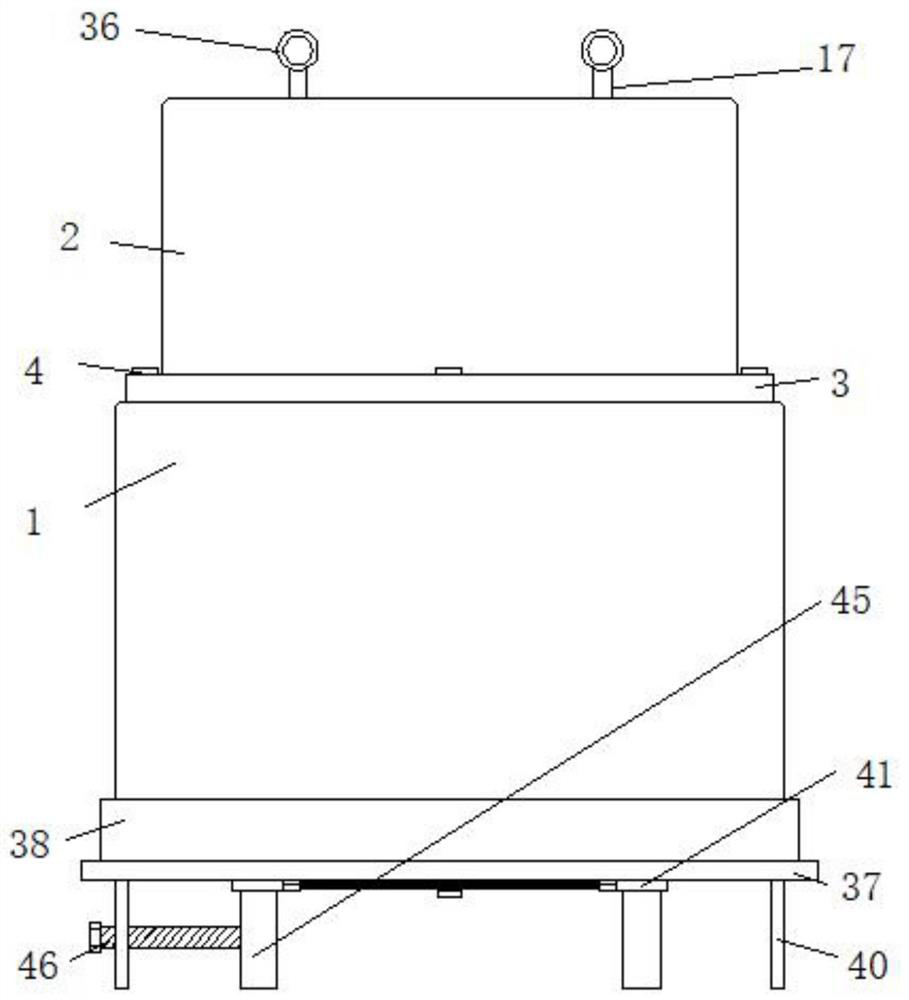

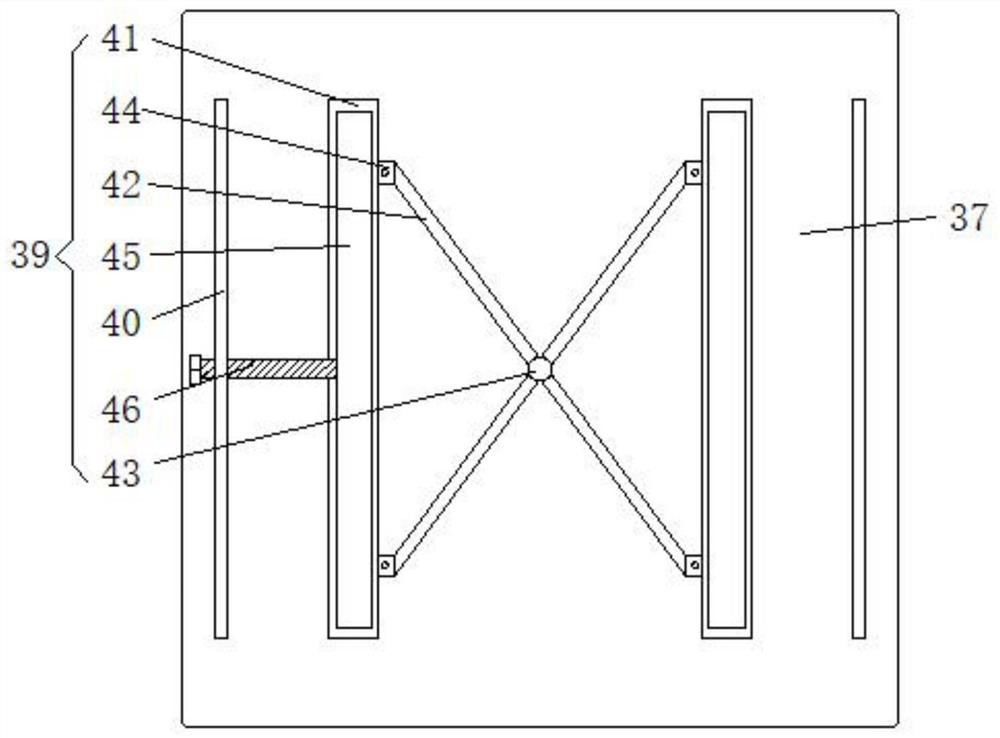

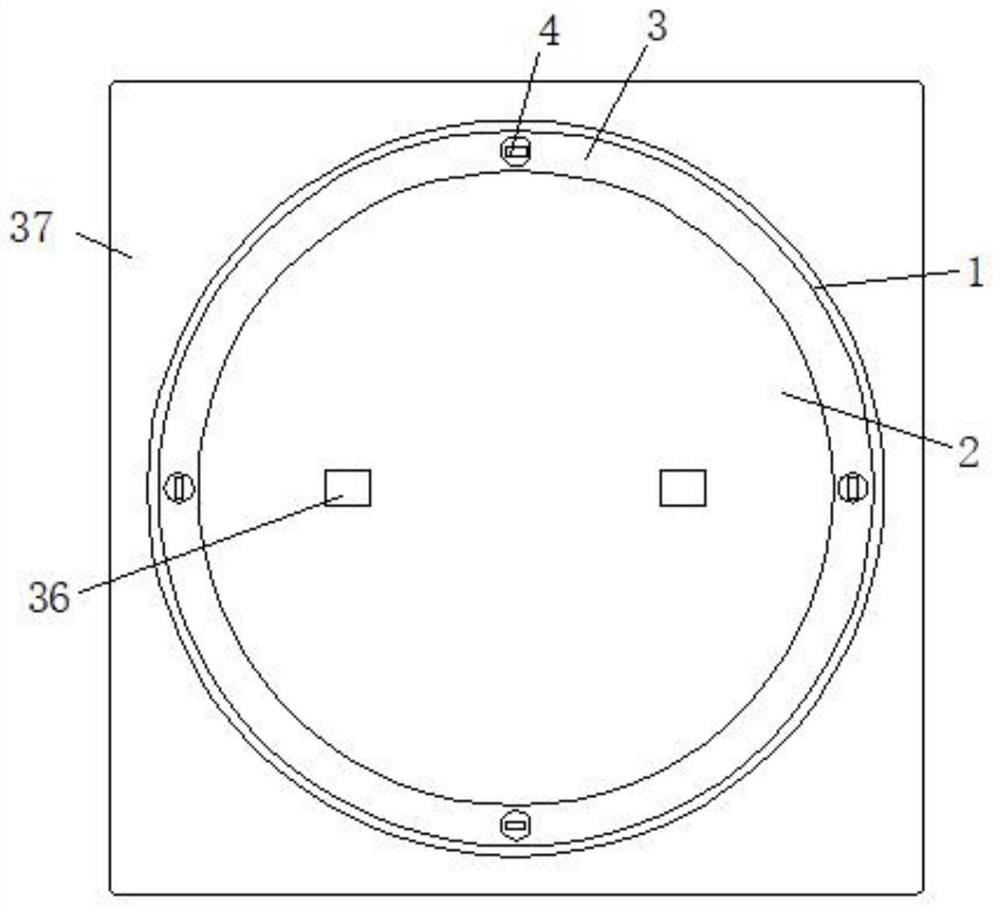

[0029] Embodiment one, such as Figure 1-7As shown, an electromagnetic switch device with adjustable force includes a first housing 1, a second housing 2 is arranged above the first housing 1, and both the first housing 1 and the second housing 2 are in a cylindrical shape. , the outer diameter of the first housing 1 is greater than the outer diameter of the second housing 2, the outer wall of the second housing 2 is fixedly connected with a connecting ring 3, the connecting ring 3 is welded to the second housing 2, and the connecting ring 3 is connected by a plurality of connecting screws 4. It is fixedly connected with the upper wall of the first shell 1. The bottom surface of the first shell 1 is threadedly connected with the installation cylinder 5. The bottom surface of the installation cylinder 5 is provided with a concave groove, which is convenient for rotating installation. The upper surface of the installation cylinder 5 is fixedly connected with the installation ring...

Embodiment 2

[0030] Embodiment two, such as Figure 4 , 7 As shown, the outer sides of the two first contacts 13 are horizontally provided with installation grooves 23, and the two installation grooves 23 are fixedly connected with the inner wall of the second housing 2. The two installation grooves 23 are arranged symmetrically, and the installation grooves 23 Located between the first contact 13 and the second contact 16, a groove 24 is horizontally arranged on the side of the installation groove 23 facing the fixed iron core 7, and a vertically arranged moving piece 25 is slidably connected in the groove 24 to move The sheet 25 is fixedly connected to the inner wall of the groove 24 through the extrusion spring 26, and the side of the moving sheet 25 facing the fixed iron core 7 is fixedly connected with a deceleration rod 27 arranged horizontally, and the end of the deceleration rod 27 away from the moving sheet 25 is fixedly connected with a deceleration block 28. The deceleration bl...

Embodiment 3

[0031] Embodiment three, such as Figure 4 , 6 As shown, a stabilizing ring 30 is provided above the two second contacts 16, and the two stabilizing rings 30 are respectively sleeved on the corresponding movable rods 17 and slidably connected thereto. The rod 31 is fixedly connected to the inner wall of the second housing 2, and the two stabilizing rings 30 are fixedly connected through two arc-shaped linkage rods 32. The stabilizing ring 30 is used to limit the movable rod 17 and determine the moving direction of the movable rod 17. The moving rod 17 can only move up and down, so as to ensure the accurate docking of the second contact 16 and the first contact 13 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com