Electric spark corrosion method for removing conductive material of printed circuit

A technology of conductive materials and printed circuits, which is applied in the field of electric spark corrosion for the removal of conductive materials of printed circuits, and can solve problems such as interruptions in the etching process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

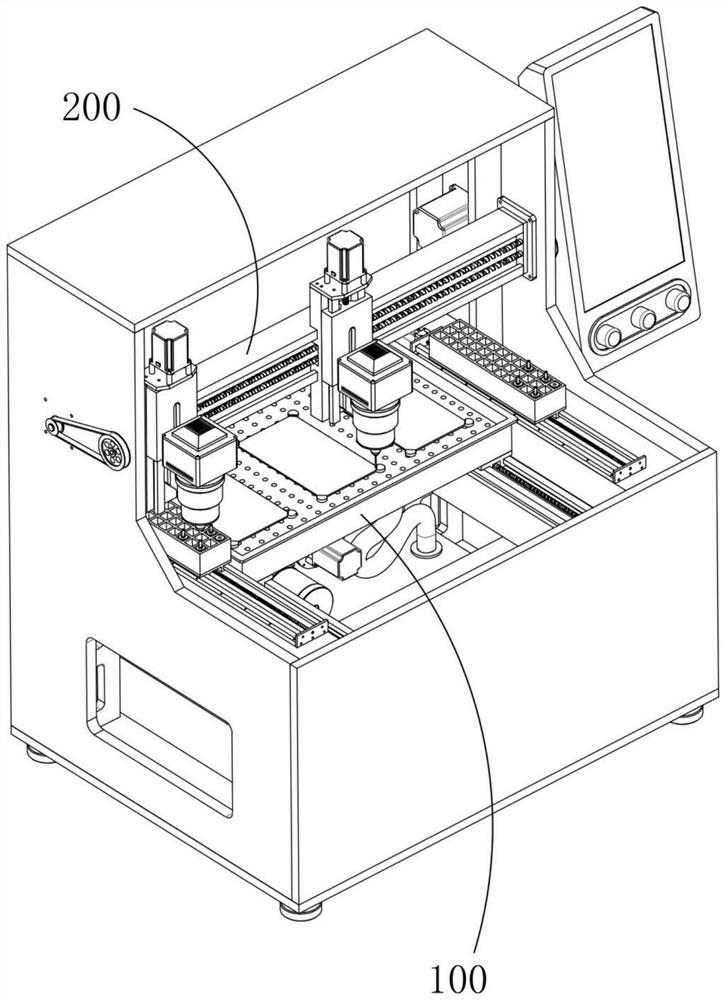

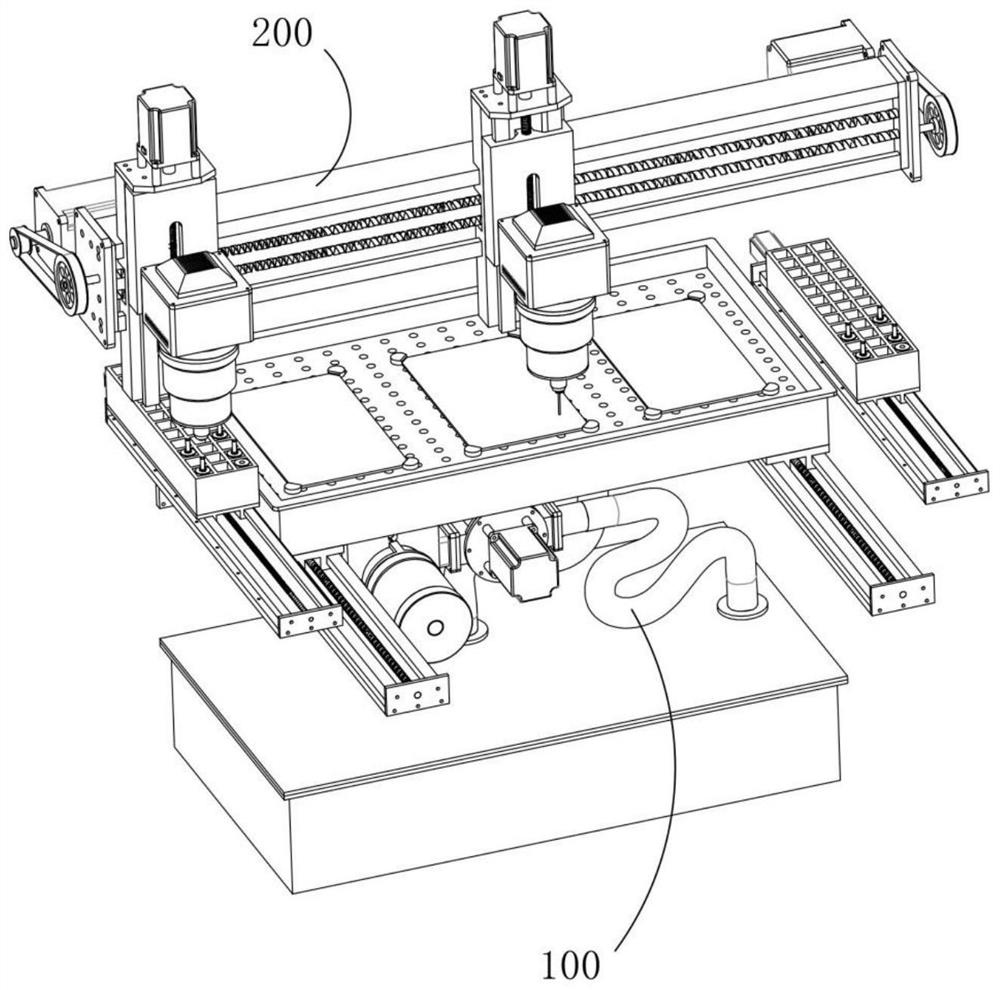

[0087] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0088] An electric spark corrosion method for removing conductive materials of a printed circuit, the steps of which are:

[0089] (1) Preparatory stage;

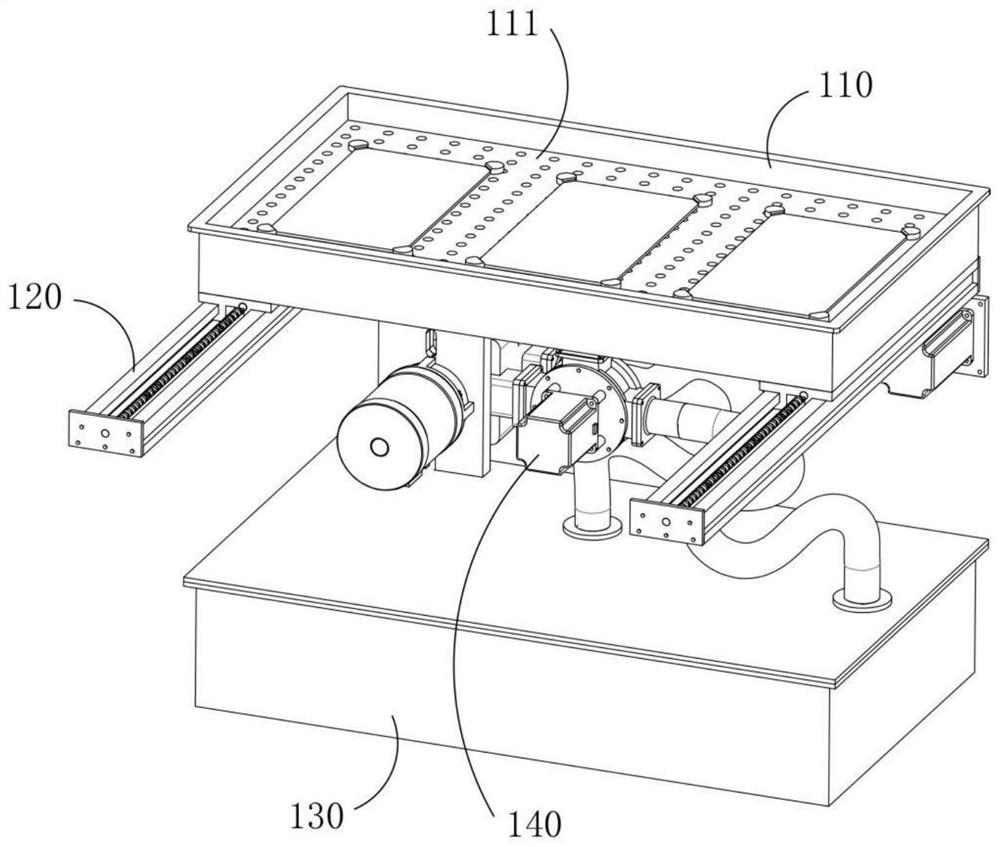

[0090] S1: The etching platform 100 includes a liquid medium storage case 110, an X-axis displacement mechanism 120, a filter box 130, and a suction mechanism 140. A support plate 111 is horizontally arranged in the liquid medium storage case 110, and a clamp is arranged on the support plate 111. The holding part is used to place the printed circuit board on the upper end surface of the supporting plate 111 through the holding part;

[0091] S2: The water pump 141 in the suction mechanism 140...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com