Cowcatcher with passive turbulent flow structure and application thereof

An obstacle remover and streamlined technology, applied in the direction of railway vehicle wheel guards/bumpers, railway car body parts, transportation and packaging, etc., can solve the problem of small peak noise suppression, limited effect of shear layer control, near-field noise Analyze fewer problems to achieve the effect of reducing excitation, reducing impact, and reducing peak noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

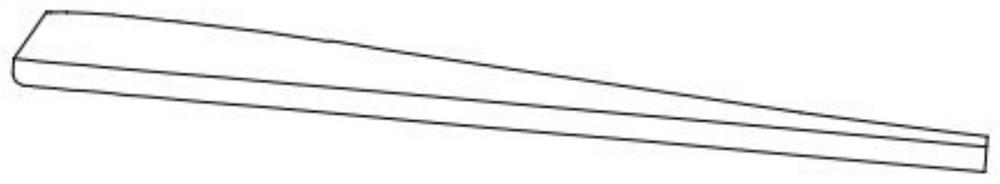

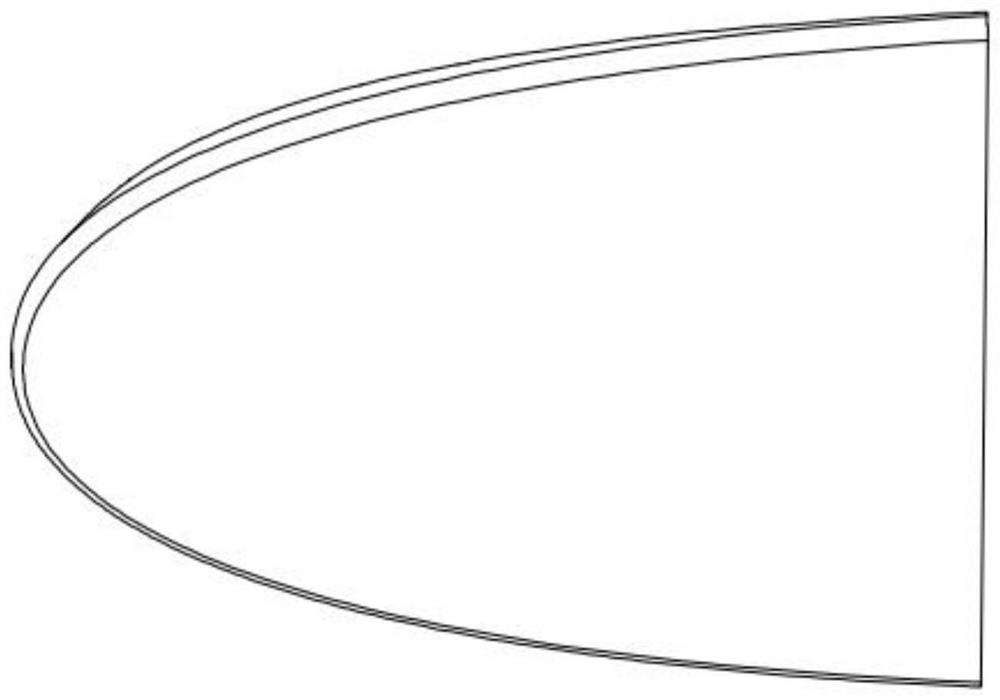

[0030] Figure 1-Figure 2 It is a schematic structural diagram of an ordinary obstacle remover, which does not have the function of reducing the aerodynamic noise in the bogie area of the front of the high-speed train.

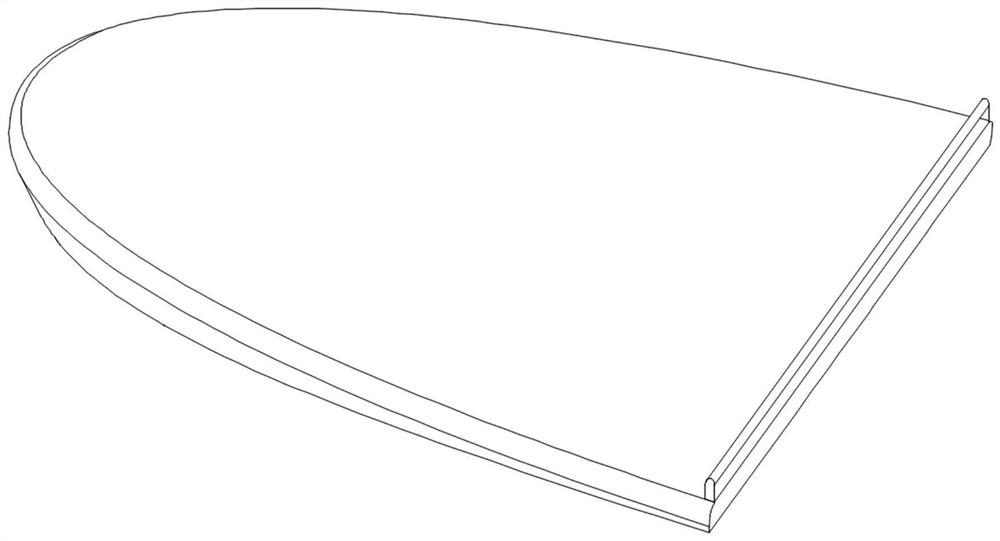

[0031] In order to effectively control the aerodynamic noise generated by the operation of high-speed trains, the present invention provides a barrier remover with a passive spoiler structure for reducing the aerodynamic noise in the bogie area of the high-speed train head, such as Figure 3-Figure 4 As shown, including the obstacle remover body 1, the obstacle remover body 1 is a flat structure with a variable cross-section and streamlined shape, the front end is an upflow surface, and the bottom and rear end of the obstacle remover body 1 is provided with a cylindrical spoiler structure 2. The flow structure is hoisted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com