Positioning device for cutting optical fiber patch cord

A technology for optical fiber jumpers and positioning devices, which is applied in the coupling of optical waveguides, etc., can solve problems such as fiber jumper looseness, and achieve the effects of avoiding eversion, improving buffer protection performance, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

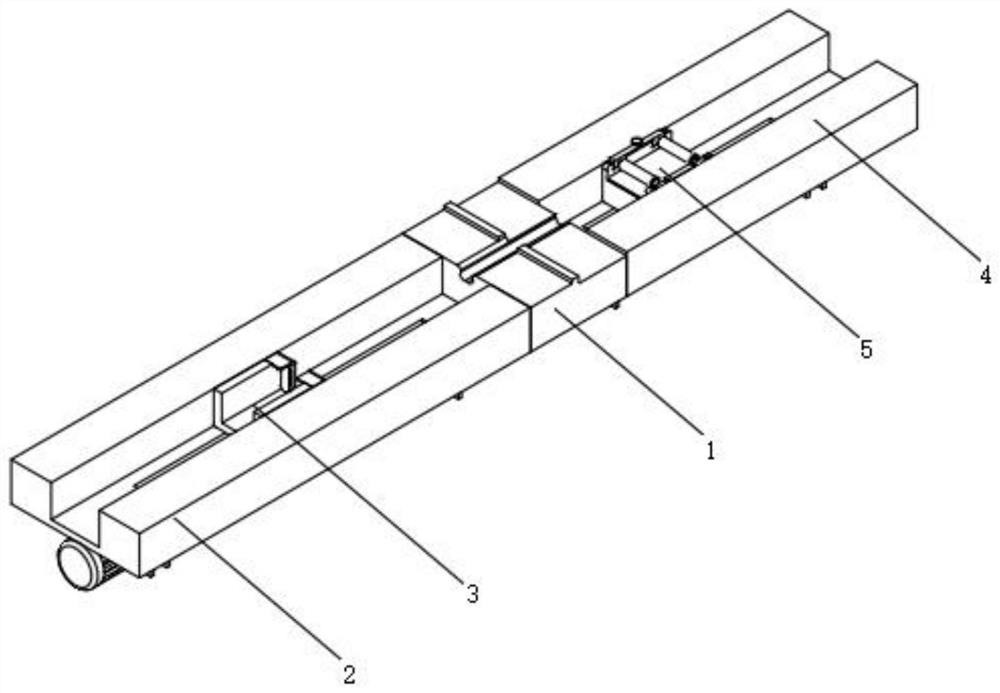

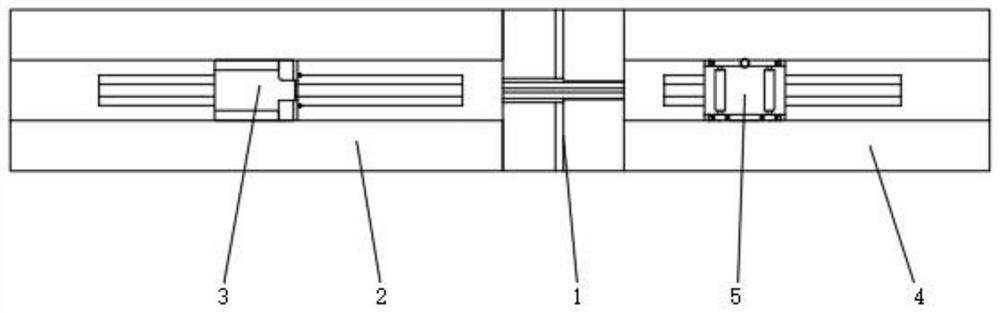

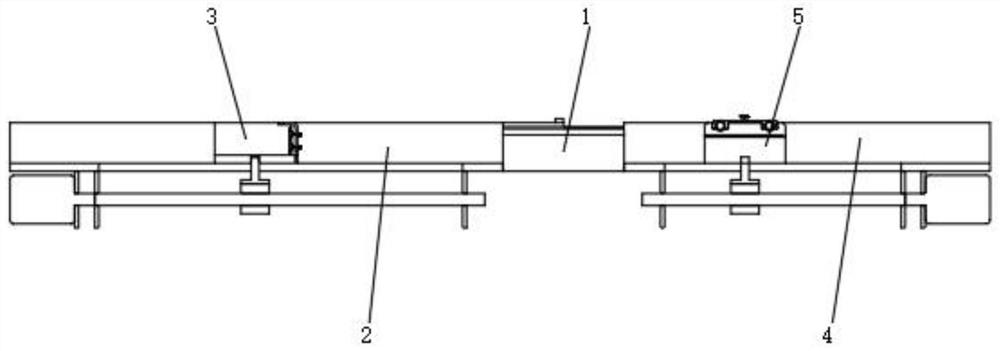

[0035] Such as figure 1 , 2 , 3, 4, 5, 6, 7, and 8, a positioning device for cutting optical fiber jumpers, including a cutting table 1, a first bracket 2 with a driving device and a length adjustment device 3, the first The support 2 with driving device comprises a first support frame 201 and a first chute 202, the upper end of the first support frame 201 is provided with a first chute 202, and one end of the first support frame 201 is provided with a cutting table 1, and the length is adjusted The device 3 includes a first sliding seat 301 and a joint slot 302, the first sliding seat 301 is provided in the first sliding slot 202, and the upper end of the first sliding seat 301 is provided with a joint slot 302;

[0036] The other end of the cutting table 1 is provided with a second support 4 with a driving device, and the second support 4 with a driving device includes a second support frame 401, a second chute 402, a second ball screw 403 and a second connector 404, the o...

Embodiment 2

[0041] Such as image 3 , 4 , 5, and 8, wherein the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1. For the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference is that the first bracket 2 with the driving device also includes a first ball screw 203 and a first connector 204, the lower end of the first support frame 201 is provided with a first ball screw 203, and the first ball screw The moving part of 203 is connected with a first connector 204, and the first connector 204 is inserted into the first chute 202 and connected with the first sliding seat 301;

[0042] The length adjustment device 3 also includes a U-shaped piece 303, a blocking piece 304, a movable rod 305, a back-moving spring 306, a fixed piece 307 and a buffer pad 308, and the other side of the first sliding seat 301 is provided with a U-shaped piece 303, and the U-shaped piece A stopper 304 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap