Multipurpose quick-change bottom plate assembly of sanding machine and sanding machine

A sanding machine and multi-purpose technology, which is applied in the direction of grinding/polishing equipment, grinding machines, metal processing equipment, etc., can solve the problems of reducing the use limitation of the bottom plate of the sanding machine, high investment cost of the bottom plate, and poor design rationality. To achieve the effect of improving the convenience and flexibility of disassembly and replacement, reducing the limitation of use and flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

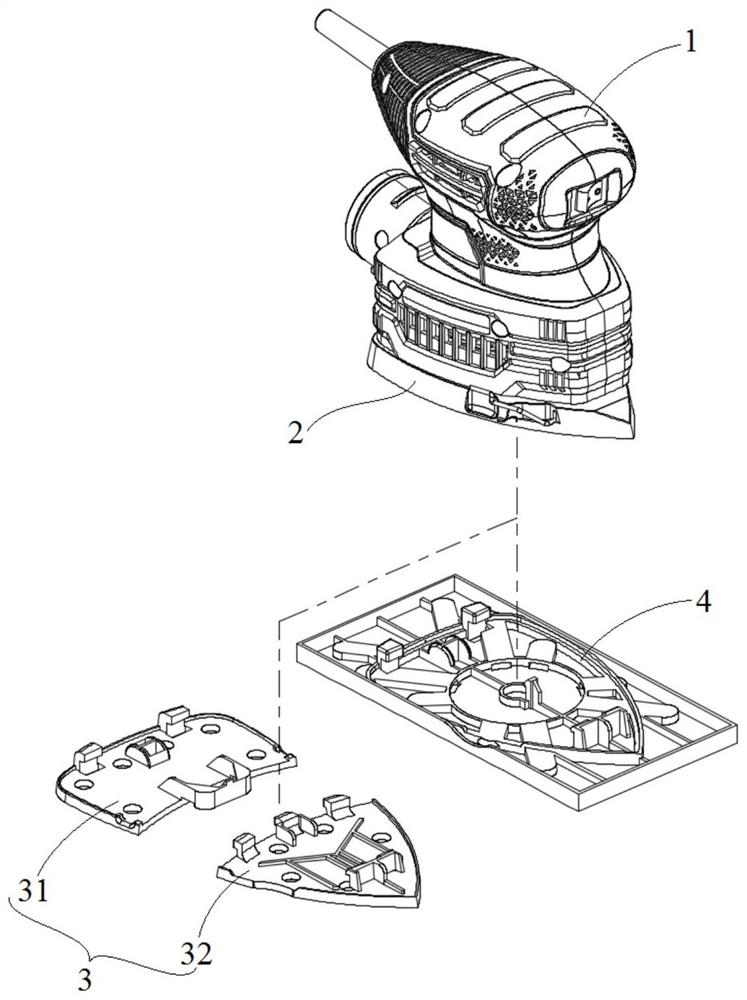

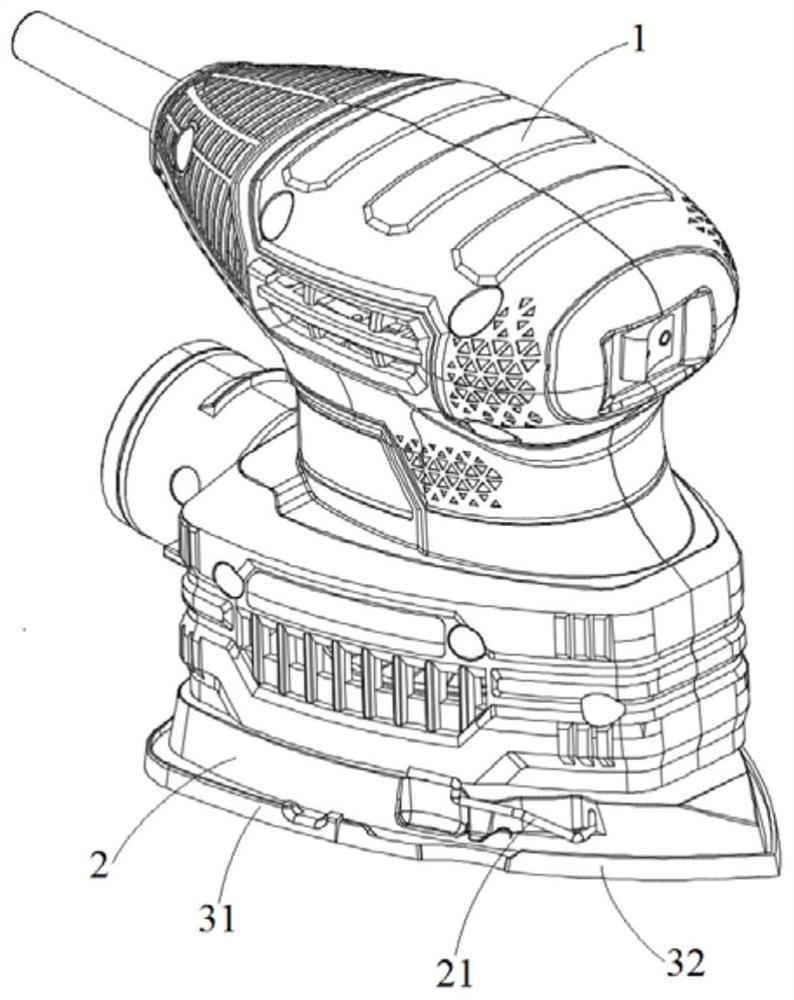

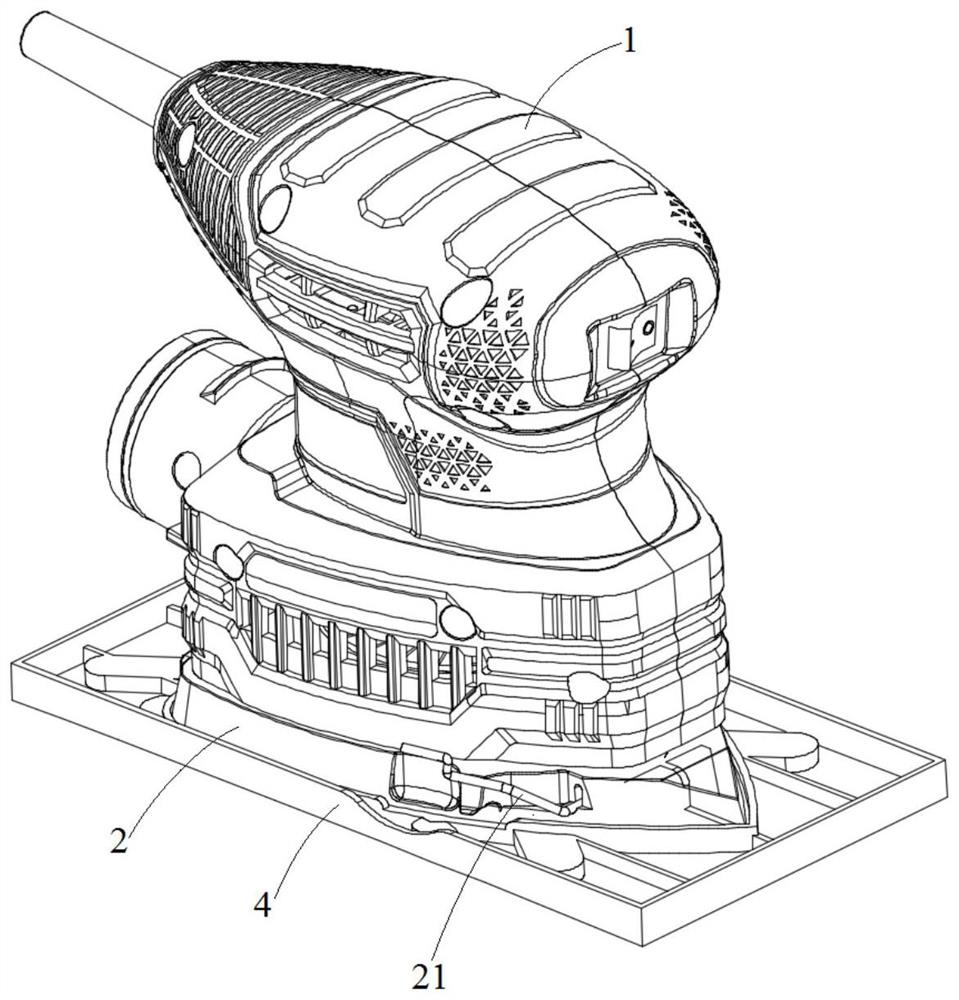

[0048] combine figure 1 As shown, a multi-purpose quick-change base plate assembly for a sander in this embodiment includes a base plate main body 2, a split base plate attachment 3 and an integrated base plate attachment 4. The split base plate attachment 3 can realize partial replacement of the base plate. The base plate attachment 4 can realize the overall replacement of the base plate, wherein: the bottom of the base plate main body 2 is provided with a front base plate buckle installation area and a rear base plate buckle installation area, and the front base plate buckle installation area or the rear base plate buckle installation area is provided with a Locking mechanism for locking or unlocking; the split base plate attachment 3 includes a rear base plate attachment 31 and a front base plate attachment 32, the rear base plate attachment 31 is fastened and installed in the rear base plate fastening installation area of the base plate main body 2, and the front base pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com