Spraying device applied to production and processing of plastic housing of unmanned aerial vehicle for plant protection

A technology of spraying device and machine plastic, which is applied in the direction of spraying device and spray booth, etc., can solve the problems of low reliability of use, high use limitation, and inconvenient operation when changing the spraying position of the plastic shell.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

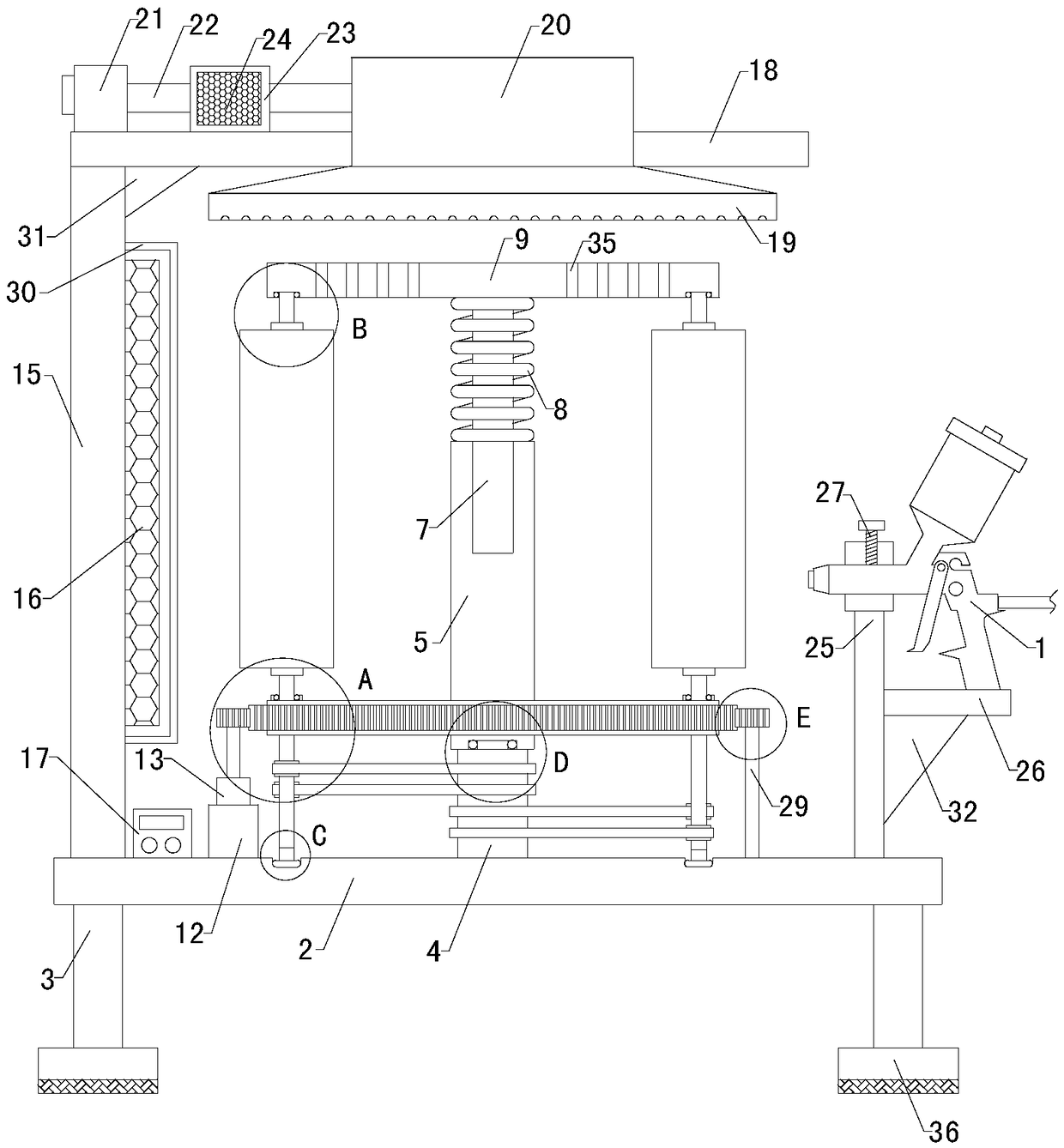

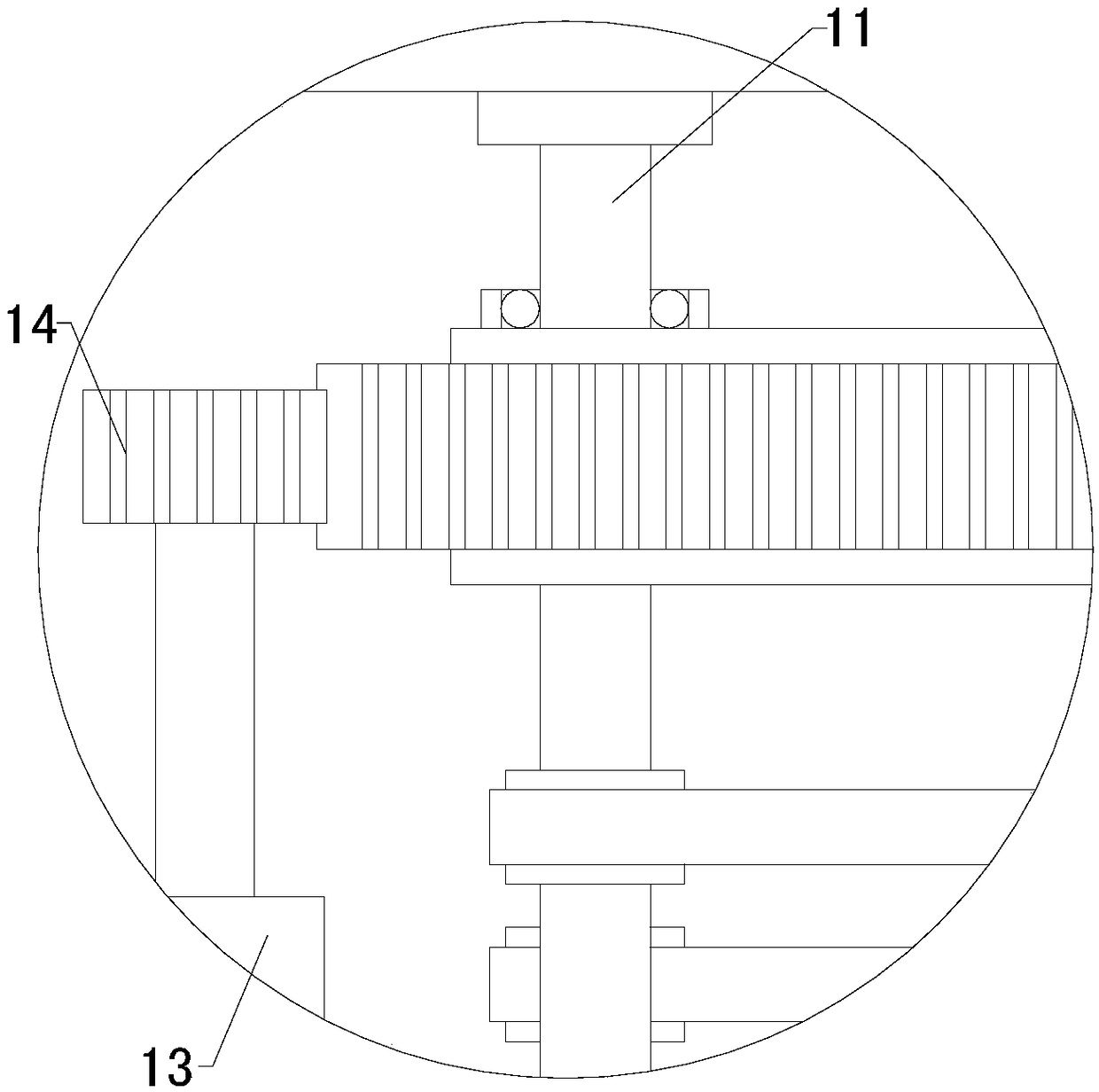

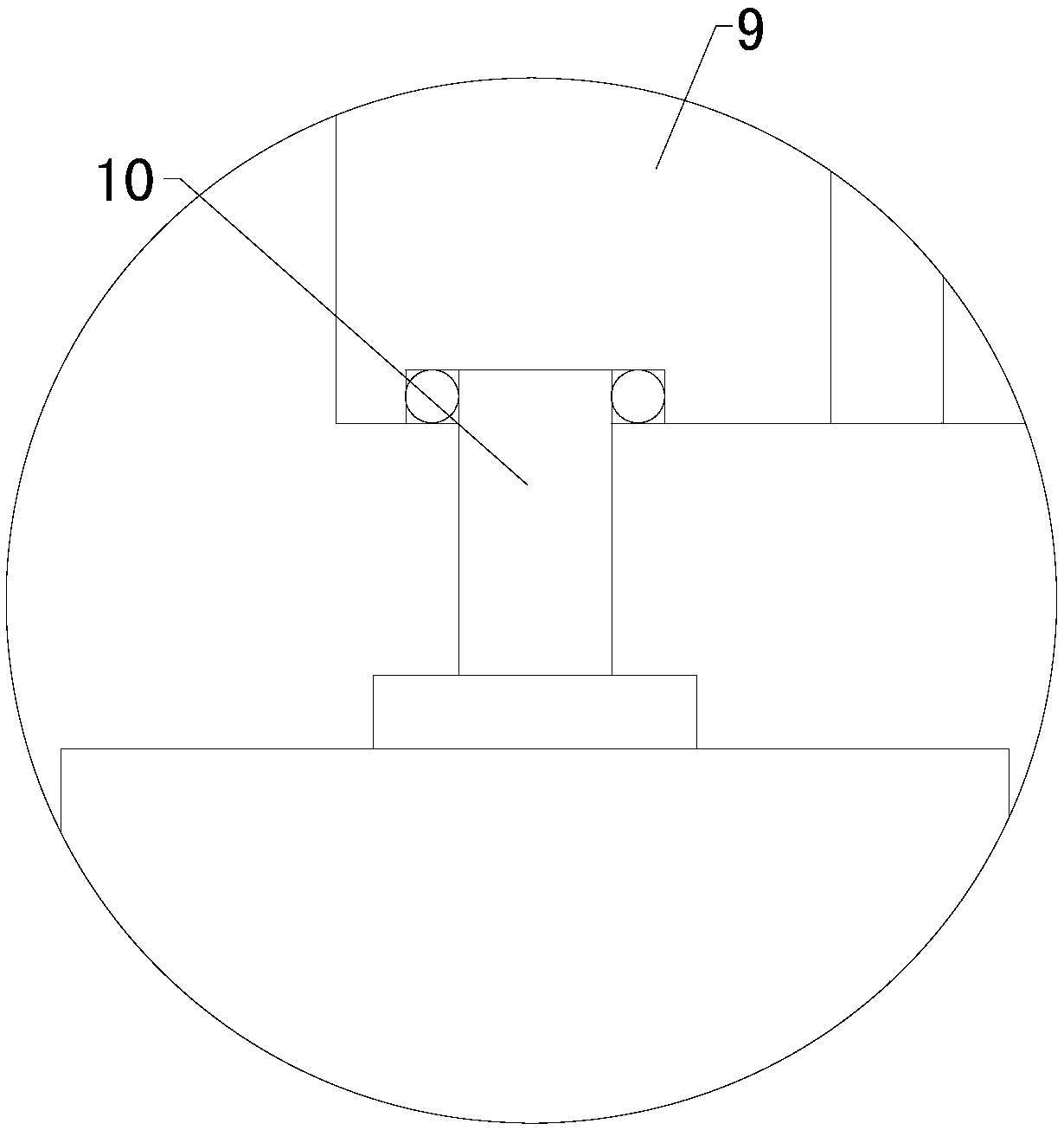

[0025] Such as Figure 1 to Figure 8 As shown, a spraying device for the production and processing of plastic casings of plant protection drones of the present invention includes a spray gun 1 and an operating table 2, and the left front side, left rear side, right front side and right rear side of the bottom end of the operating table 2 are longitudinally provided with The legs 3, and the spray gun 1 is located on the console 2, and the spray gun 1 is connected with a watering pot; including a fixed column 4, a support column 5, a rotating shaft 6, a limit square column 7, a compression spring 8, an upper pressure plate 9, a lower The pressure plate, four sets of auxilia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com