Generator assembling equipment and operation method

A technology for assembling equipment and generators, applied to workpiece clamping devices, manufacturing tools, etc., can solve the problems of time-consuming and laborious tower installation, difficult positioning of towers, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below according to accompanying drawing and embodiment the present invention will be described in further detail:

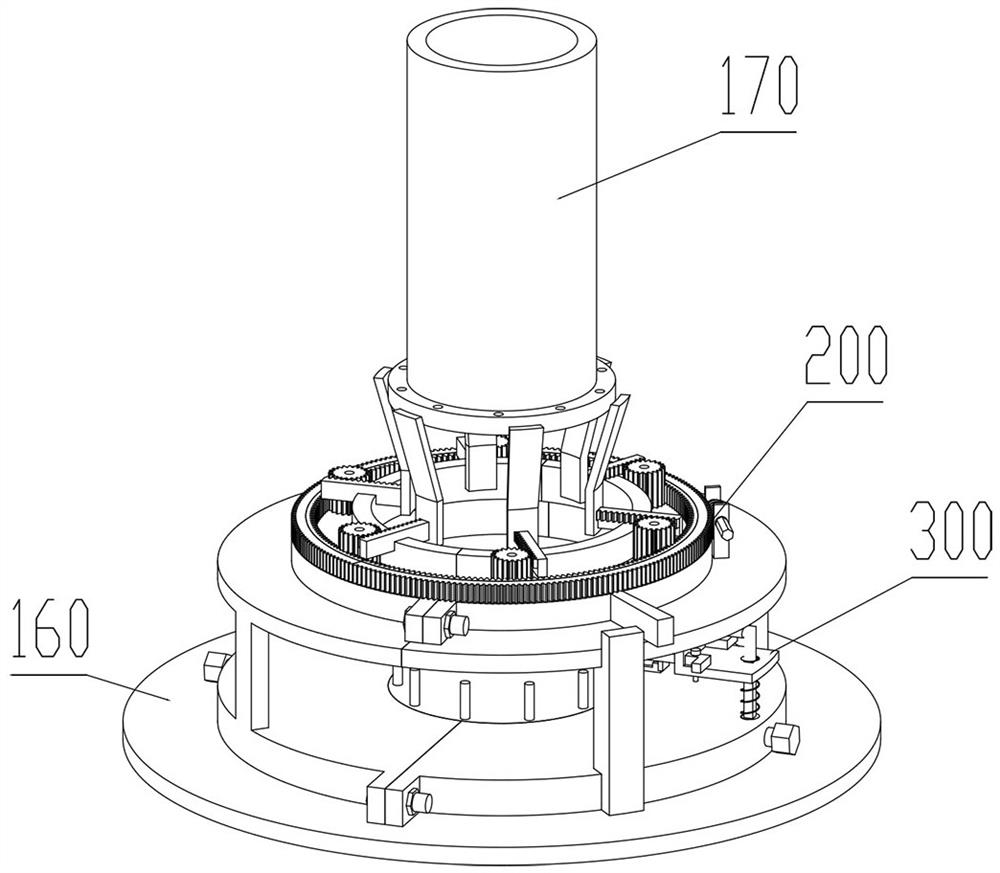

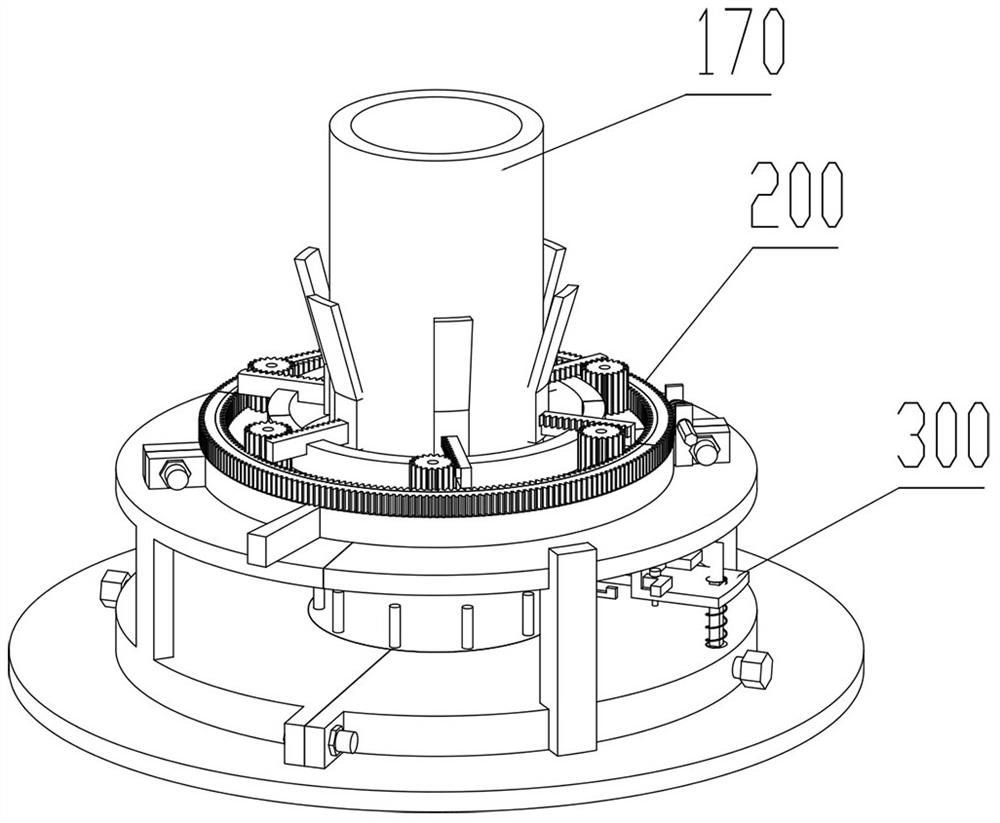

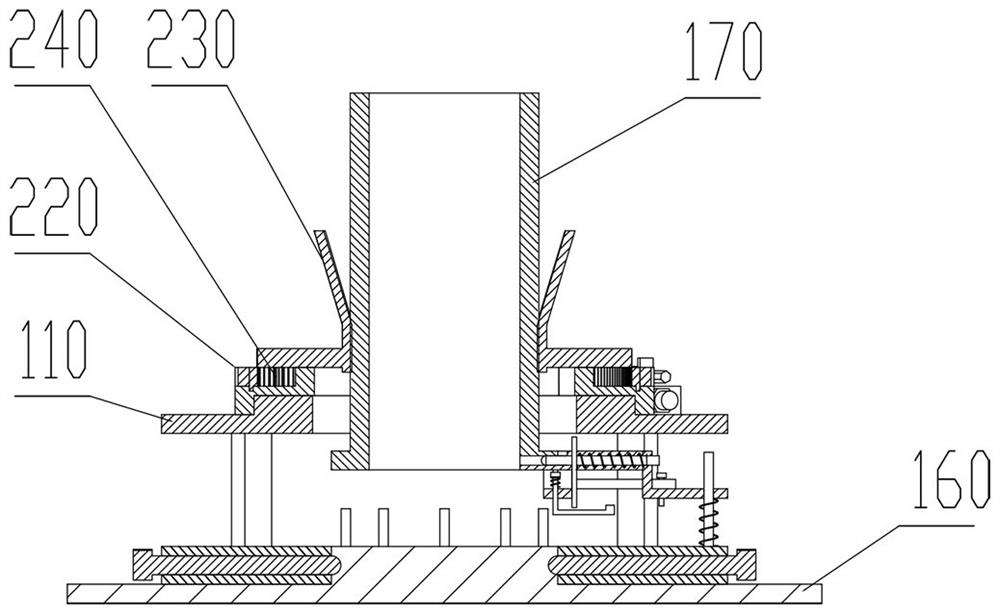

[0036]A generator assembly equipment and operation method, including a machine base 110, a positioning bolt 130, a No. 1 spring 140, a worm 150, a foundation 160, a tower 170, a clamping device 200, and a positioning device 300. The machine base 110 has a The machine base hole 111, the machine base hole 111 has a through machine base positioning hole 112 in the radial direction, the machine base 110 has symmetrically arranged machine base ear plates 113 on the front and rear sides, and the machine base ear plate 113 has a machine base ear plate hole 114 in the middle, There is a square shaft 119 on the outside of the end face of the machine base 110, and a plurality of connecting plates 115 are evenly distributed in the circumferential direction of the machine base 110. The upper part of the connecting plate 115 has an upper plate 116, and the upper plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com