Municipal construction guardrail with collision buffering function

A municipal and functional technology, applied in roads, buildings, road safety devices, etc., can solve problems such as unstable operation of equipment, equipment dumping, and inability to buffer protection, etc., to achieve the effect of improving the protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

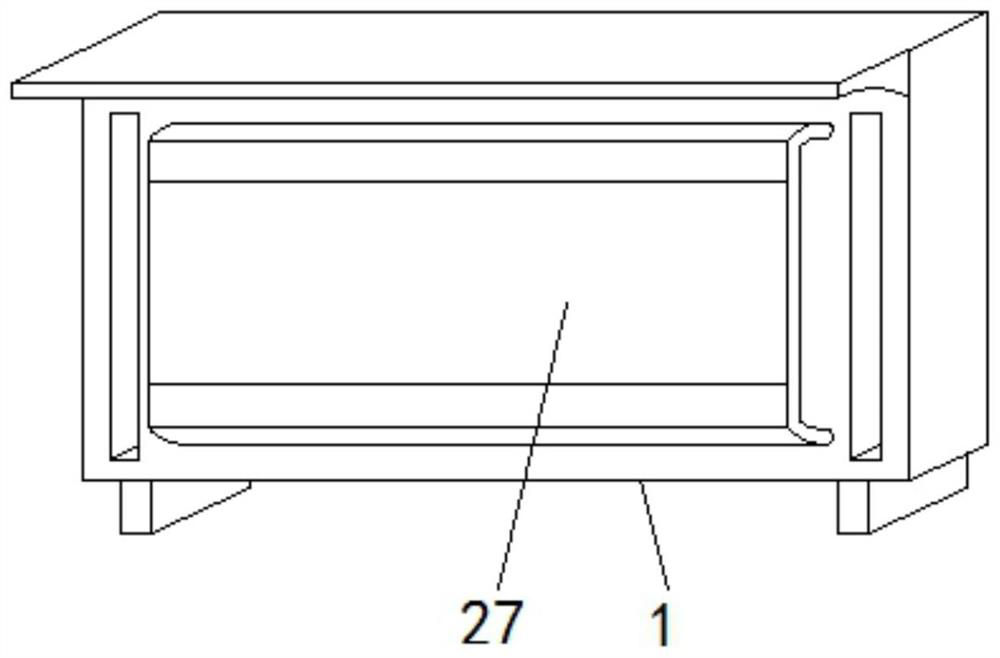

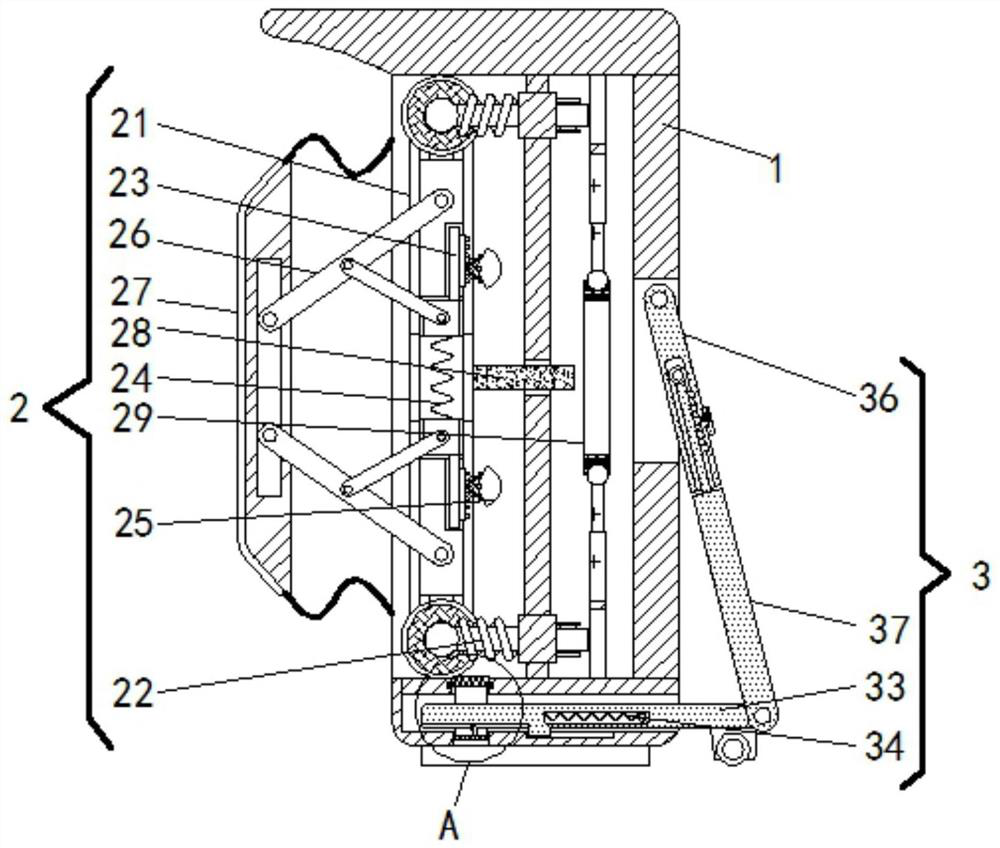

[0023] see figure 2 with Figure 5 , a guardrail for municipal construction with a collision buffer function, comprising a housing 1, the inner cavity of the housing 1 is movably connected with a buffer mechanism 2, the buffer mechanism 2 includes a sliding frame 21, and the upper and lower ends of the sliding frame 21 are rotatably connected with The running wheel and the front and rear sides of the running wheel are fixedly sleeved with rubber bladders, which communicate with the middle of the inner cavity of the sliding frame 21, so that the air inside the sliding frame 21 can be squeezed when the gear block 23 moves for buffering. Into the rubber bladder, so that it expands and contacts the inner wall of the housing 1 to increase friction and relieve the impact force. The right part of the inner cavity of the housing 1 is slidably inserted with a buffer column 22 extending to the edge of the sliding frame 21. The sliding frame 21 The middle part of the inner cavity is sl...

Embodiment 2

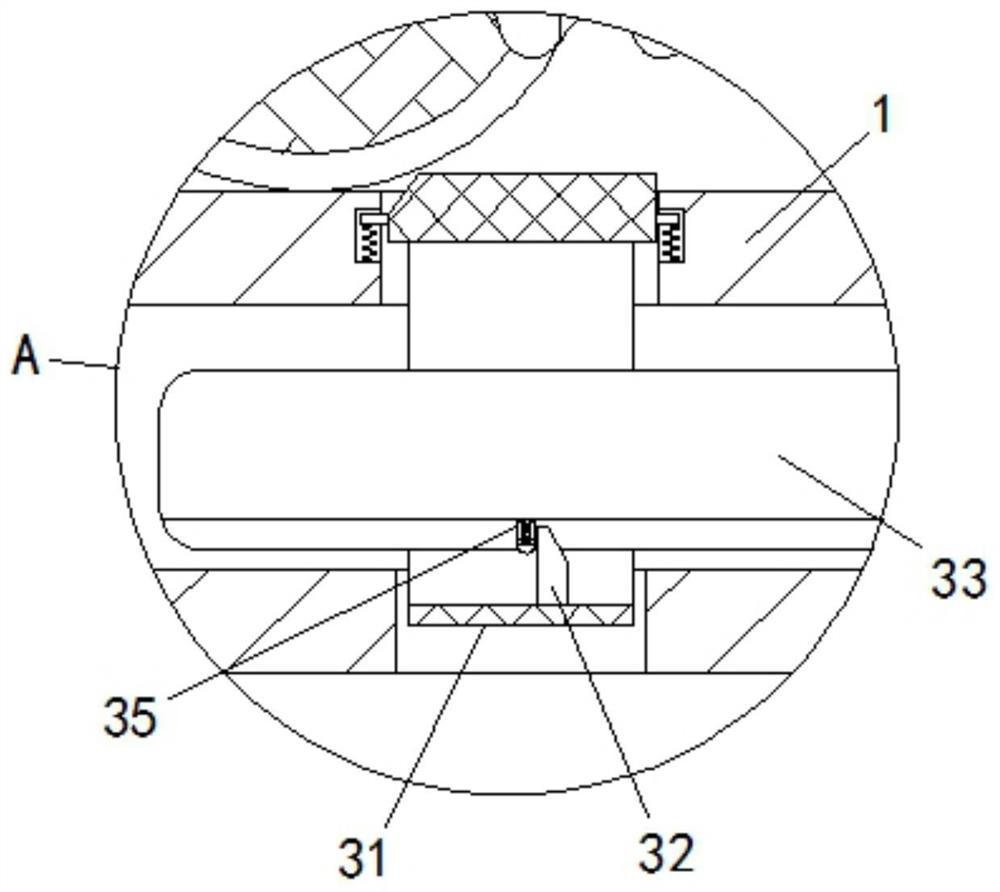

[0025] see Figure 2-Figure 4 , a guardrail for municipal construction with a collision buffer function, further comprising a stabilizing mechanism 3 movably connected to the right wall of the casing 1, the stabilizing mechanism 3 comprising a special-shaped frame 31, the upper end of the special-shaped frame 31 is close to the sliding frame 21 One side is provided with an inclined slope, so that the special-shaped frame 31 is squeezed when the sliding frame 21 moves to the right. The lower wall of the inner cavity of the special-shaped frame 31 is fixedly connected with a wedge-shaped column 32, and the side of the wedge-shaped column 32 close to the telescopic column 35 is designed. There is a right-angled surface, so that it is convenient to initially limit the telescopic column 35, so that the extension bar 33 cannot be ejected under the elastic force of the compression spring 34, and the bottom inner cavity of the housing 1 is slidably plugged with an extension bar extendi...

Embodiment 3

[0027] see Figure 1-Figure 5, a guardrail for municipal construction with a collision buffer function, comprising a housing 1, the inner cavity of the housing 1 is movably connected with a buffer mechanism 2, the buffer mechanism 2 includes a sliding frame 21, and the upper and lower ends of the sliding frame 21 are rotatably connected with The running wheel and the front and rear sides of the running wheel are fixedly sleeved with rubber bladders, which communicate with the middle of the inner cavity of the sliding frame 21, so that the air inside the sliding frame 21 can be squeezed when the gear block 23 moves for buffering. Into the rubber bladder, so that it expands and contacts the inner wall of the housing 1 to increase friction and relieve the impact force. The right part of the inner cavity of the housing 1 is slidably inserted with a buffer column 22 extending to the edge of the sliding frame 21. The sliding frame 21 The middle part of the inner cavity is slidingly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com