Water boiling device for water boiling test of composite cross arm and use method of water boiling device

A technology for test and water inlet device, applied in measurement device, short-circuit test, environment/reliability test, etc., can solve the problems of easily scalded experimenter, increased heater load, large temperature change, etc., to achieve heat recovery effect Good, reduce the load, the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

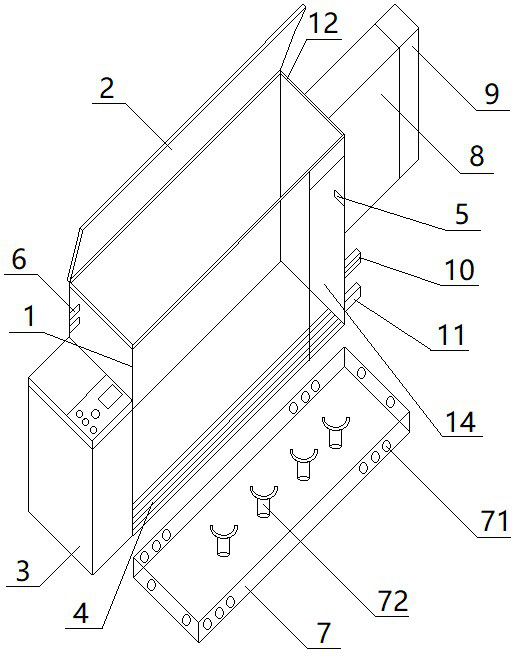

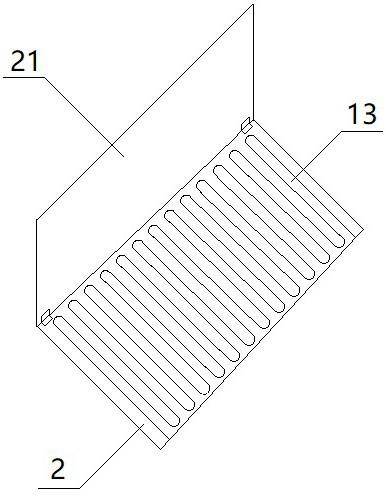

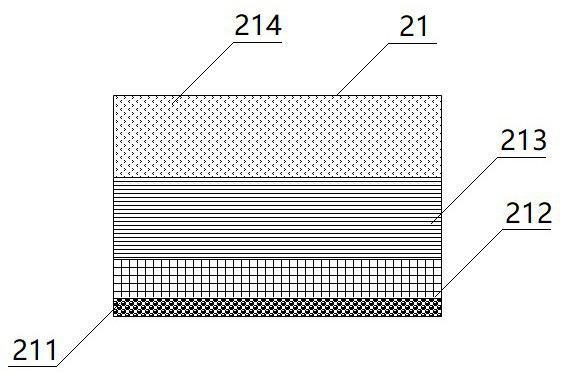

[0047] A composite horizontal arm poaching test poaching device, the poaching device comprises: a poaching box body 1 with an upper opening, a poaching box cover 2, a control host 3, a heater 4, a temperature detection device 5, and a liquid level controller 6. The composite cross-arm placement box 7, the first water storage tank 8, and the second water storage tank 9; the boiling tank body 1 is provided with a water inlet device 10 and a water outlet device 11 communicating with the boiling tank body 1 , the top is matched with a boilable tank cover 2 that can be opened and closed, a temperature detection device 5 and a liquid level controller 6 are arranged on the inner wall, and a heat preservation baffle 12 is arranged on the outer wall, and the heat preservation baffle 12 is phenolic foam plastic plate, the thickness of the phenolic foam plastic plate is 5 cm, and a heater 4 is arranged on the inner bottom plate;

[0048] The water inlet device 10 is connected with the fi...

Embodiment 2

[0061] A composite horizontal arm poaching test poaching device, the poaching device comprises: a poaching box body 1 with an upper opening, a poaching box cover 2, a control host 3, a heater 4, a temperature detection device 5, and a liquid level controller 6. The composite cross-arm placement box 7, the first water storage tank 8, and the second water storage tank 9; the boiling tank body 1 is provided with a water inlet device 10 and a water outlet device 11 communicating with the boiling tank body 1 , the top is matched with a boilable tank cover 2 that can be opened and closed, a temperature detection device 5 and a liquid level controller 6 are arranged on the inner wall, and a heat preservation baffle 12 is arranged on the outer wall, and the heat preservation baffle 12 is phenolic foam plastic plate, the thickness of the phenolic foam plastic plate is 8 cm, and a heater 4 is arranged on the inner bottom plate;

[0062] The water inlet device 10 is connected with the fi...

Embodiment 3

[0075] A composite horizontal arm poaching test poaching device, the poaching device comprises: a poaching box body 1 with an upper opening, a poaching box cover 2, a control host 3, a heater 4, a temperature detection device 5, and a liquid level controller 6. The composite cross-arm placement box 7, the first water storage tank 8, and the second water storage tank 9; the boiling tank body 1 is provided with a water inlet device 10 and a water outlet device 11 communicating with the boiling tank body 1 , the top is matched with a boilable tank cover 2 that can be opened and closed, a temperature detection device 5 and a liquid level controller 6 are arranged on the inner wall, and a heat preservation baffle 12 is arranged on the outer wall, and the heat preservation baffle 12 is phenolic foam plastic plate, the thickness of the phenolic foam plastic plate is 6cm, and a heater 4 is arranged on the inner bottom plate;

[0076] The water inlet device 10 is connected with the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com