Carbon fiber cylinder herringbone lifting unit

A lift unit, carbon fiber technology, used in motor vehicles, lifting devices, transportation and packaging, etc., can solve problems such as safety limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

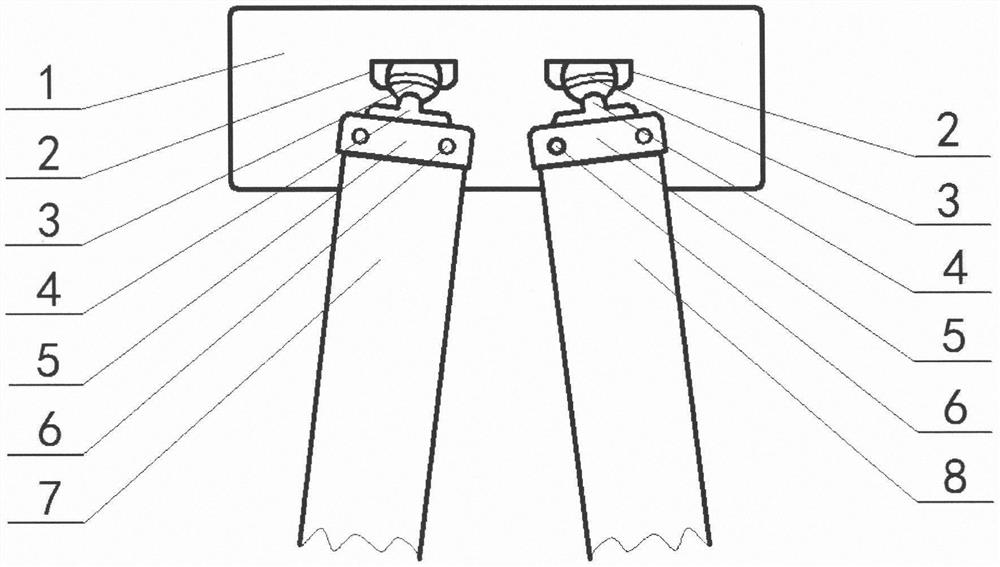

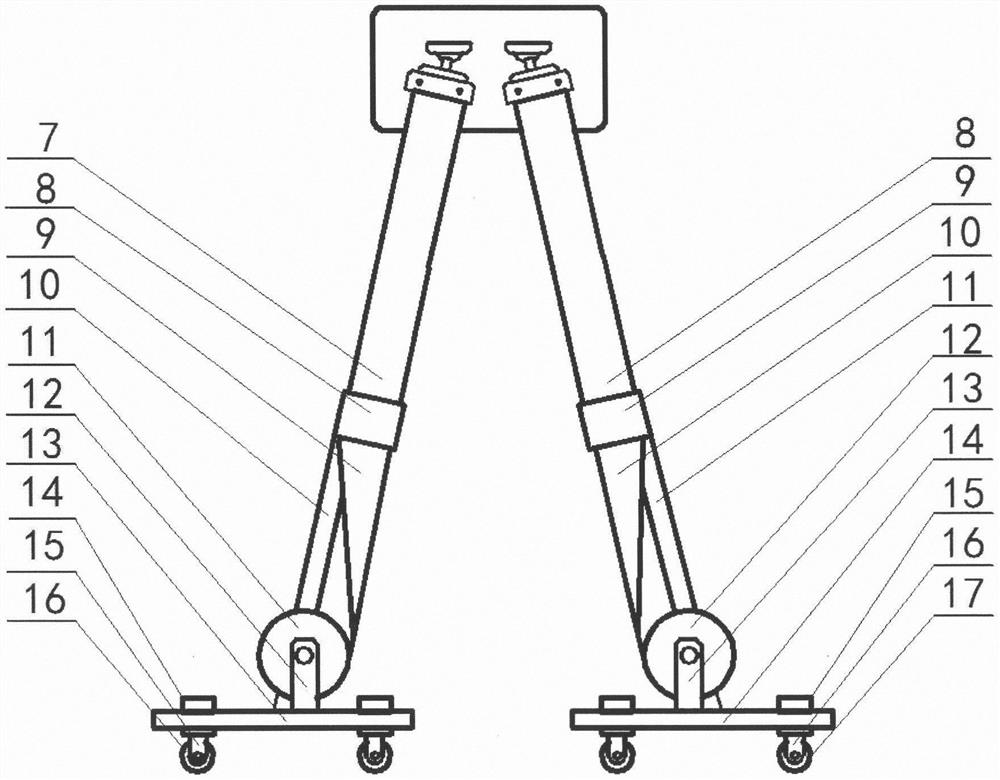

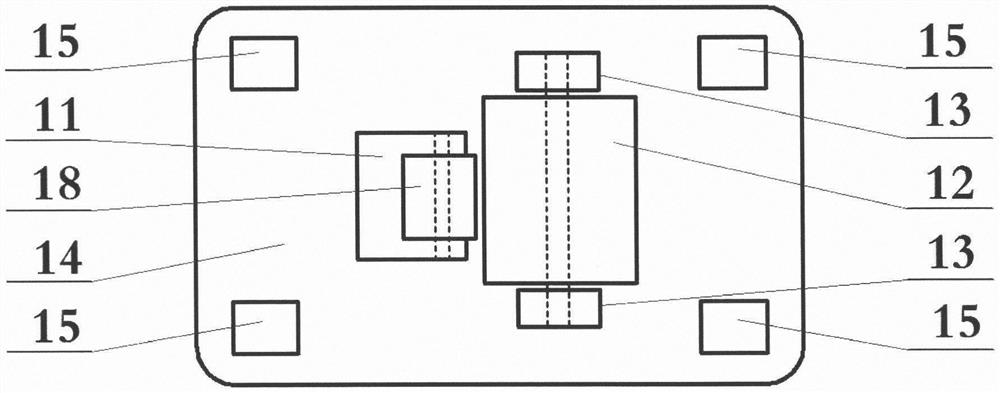

[0014] Below in conjunction with accompanying drawing, the present invention is described in more depth;

[0015] There are two radial joint bearings (2) and two radial joint bearings (3) below the aerial work platform (1) which consist of two "T" shaped shafts (4), two connecting caps (5) and two Two rivets (6) are respectively connected with the left carbon fiber column (7) and the right carbon fiber column (8) to form a carbon fiber cylinder "herringbone" type lifting frame. When the aerial work platform (1) is lowered downward, the left After the right carbon fiber column (7, (8)) passes through the shaping sealer (9), the seals of the left and right carbon fiber columns (7), (8) are pulled apart to form two carbon fiber strips (10), Roll into two reels (12) respectively, so that transport.

[0016] The left carbon fiber column (7) and the right carbon fiber column (8) are connected with the intelligent drive vehicle (14) below respectively, and four steering drive boxes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com