Flexible edge processing equipment for hook-and-loop fastener bandage of medical stretcher and process of flexible edge processing equipment

A processing equipment, Velcro technology, applied in textile and papermaking, roughening, fabric surface trimming, etc., can solve the problems of patient injury, poor touch, hard material, etc., to achieve fast bilateral soft edges, high efficiency, and degree of mechanization high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

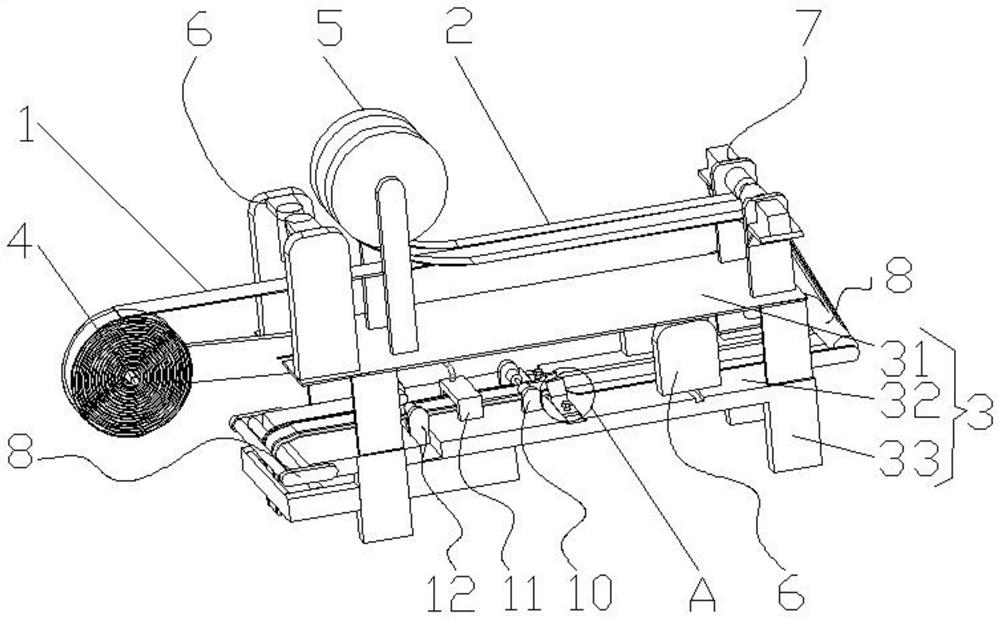

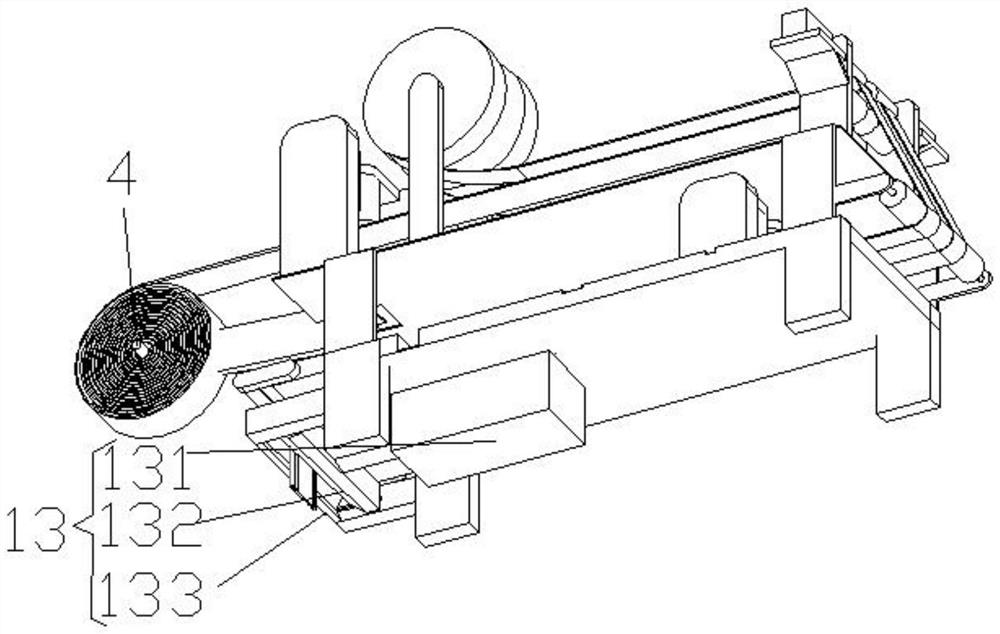

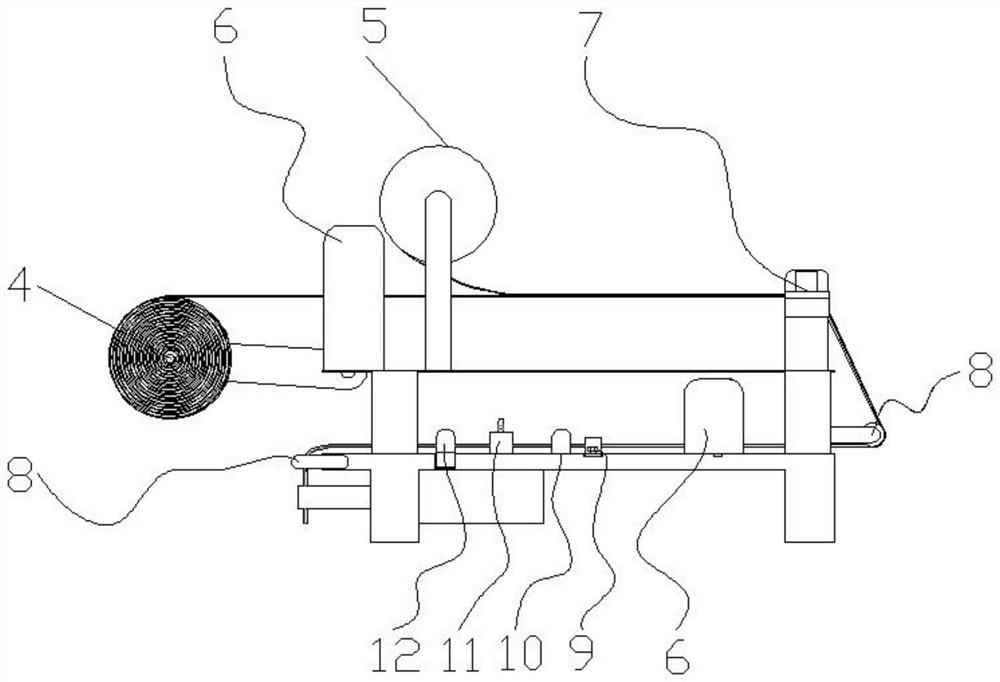

[0039] The embodiment of the present invention provides a soft edge processing equipment and technology for medical stretcher Velcro straps, such as Figure 1-10 As shown, it is used to press the fabric strip 2 on both sides of the Velcro strap 1, such as Figure 10 As shown, the two sides of Velcro strap 1 have been bonded with hemming cloth strip 2. The Velcro is divided into a male belt and a female belt. Hair, the Velcro male tape and the master tape cooperate to achieve fast bonding and separation. In this case, the Velcro strap 1 pair of male tape and the master tape are separately processed with the same equipment and process, that is, the male tape and the master tape Both sides of the fabric strip 2 are pressed together. The bristles or soft fibers on the surface of the Velcro strap 1 are not shown in the figure. The fabric strip 2 is preferably a fleece fabric, and the fabric is softer. At the same time, in the sanding process, better Brushed for added softness to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com