Low-energy-consumption submerged arc furnace for producing silicon-manganese alloy

A technology of silicon-manganese alloy and submerged arc furnace is applied in the field of low-energy consumption submerged arc furnace for producing silicon-manganese alloy, and can solve the problems of poor cooling effect, energy consumption and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

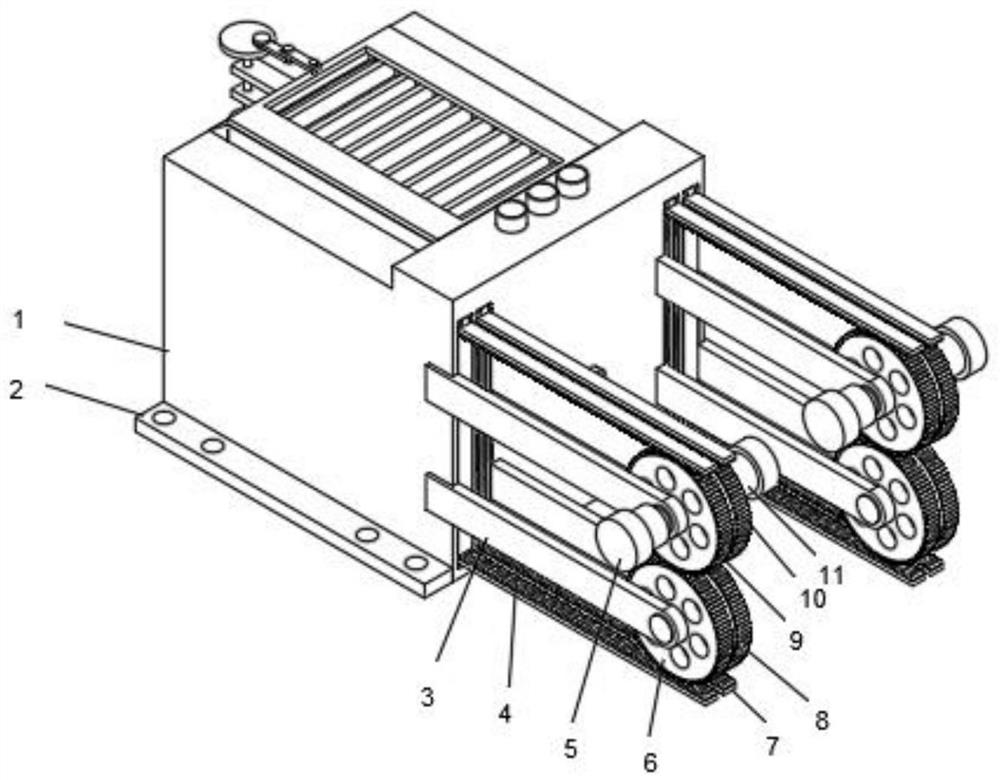

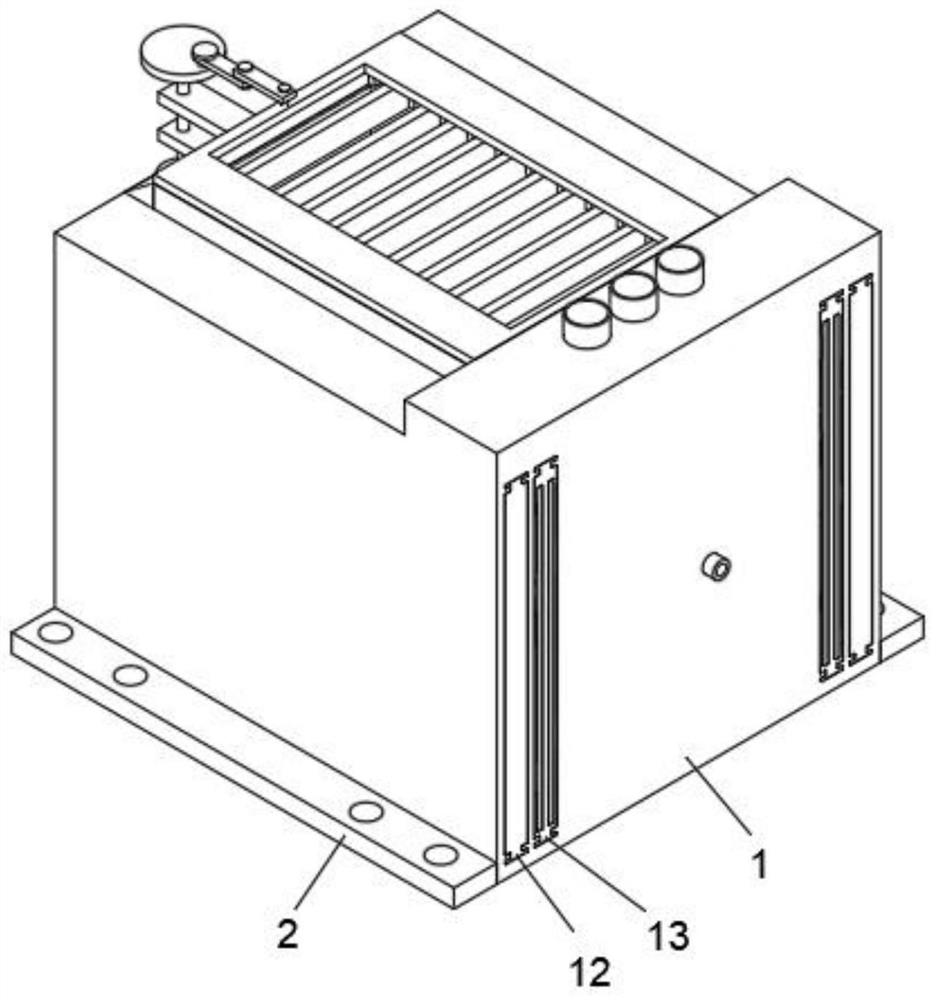

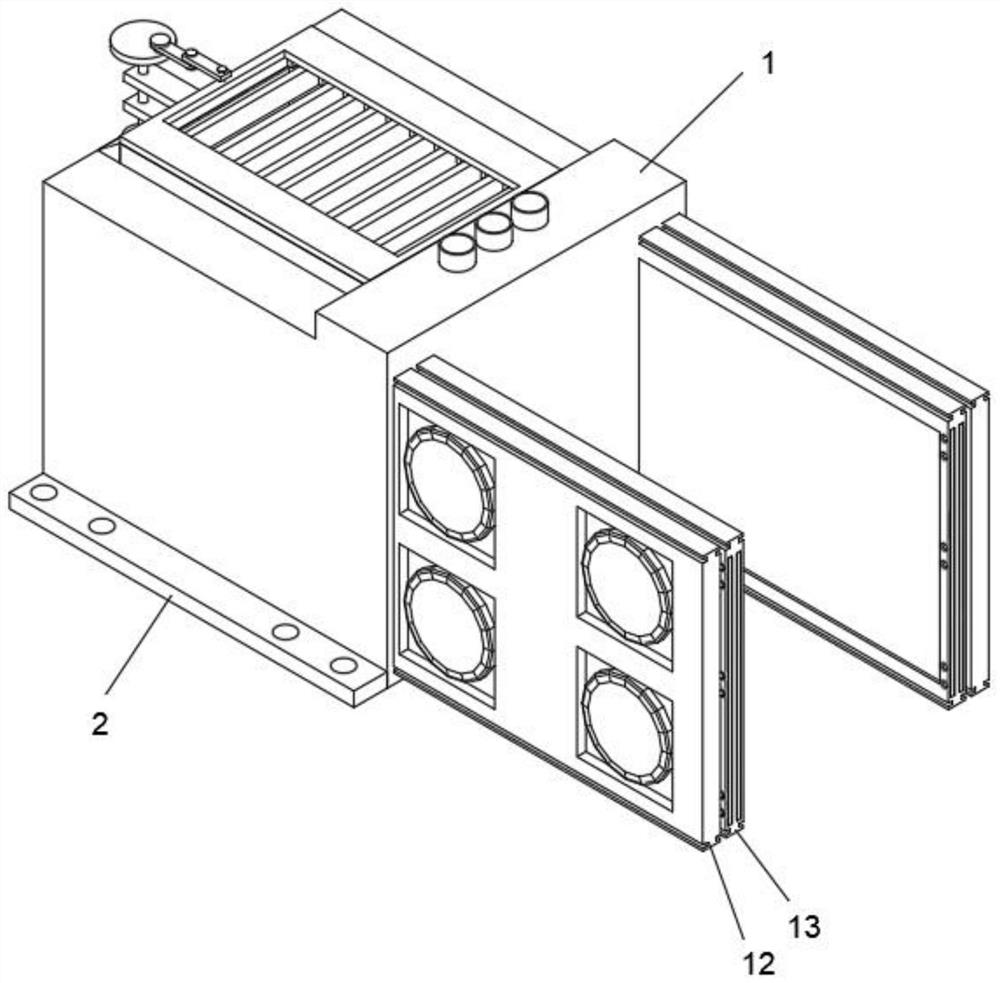

[0041] Such as Figure 1-4 , a low-energy submerged arc furnace for producing silicon-manganese alloys, comprising a submerged arc furnace body 1 and a fixing plate 2, the fixing plate 2 is fixedly installed on both sides of the bottom end of the submerged arc furnace body 1, and the submerged arc furnace body The two sides of 1 are respectively provided with a first sliding card slot 14 and a second sliding card slot 15, and the inside of the first sliding card slot 14 and the second sliding card slot 15 are connected, and the first sliding card slot 14 The cooling device 12 and the heat insulating device 13 are slidingly engaged with the inside of the second sliding slot 15 respectively. The cooling device 12 and the heat insulator 13 are respectively slidably installed on both sides of the submerged arc furnace body 1, and the heat insulator 13 is inserted into the both sides of the submerged arc furnace body 1 during the operation of the submerged arc furnace body 1, so th...

Embodiment 2

[0043] Such as Figure 1-4 , as a further optimization scheme of the above embodiment: a submerged arc furnace with low energy consumption for producing silicon-manganese alloys, comprising a submerged arc furnace body 1 and a fixing plate 2, and the fixing plate 2 is fixedly installed on the bottom end of the submerged arc furnace body 1 On both sides, the two sides of the submerged arc furnace body 1 are respectively provided with a first sliding card slot 14 and a second sliding card slot 15, and the inside of the first sliding card slot 14 and the second sliding card slot 15 are connected. A heat dissipation device 12 and a heat insulating device 13 are slidably engaged in the first sliding slot 14 and the second sliding slot 15 , respectively. Both sides of the front end of the submerged arc furnace body 1 are symmetrically fixed with a fixed installation plate 3, and the front end of the fixed installation plate 3 located on the outside is rotatably installed with a firs...

Embodiment 3

[0045] Such as Figure 1-4 , as a further optimization scheme of the above embodiment: a submerged arc furnace with low energy consumption for producing silicon-manganese alloys, comprising a submerged arc furnace body 1 and a fixing plate 2, and the fixing plate 2 is fixedly installed on the bottom end of the submerged arc furnace body 1 On both sides, the two sides of the submerged arc furnace body 1 are respectively provided with a first sliding card slot 14 and a second sliding card slot 15, and the inside of the first sliding card slot 14 and the second sliding card slot 15 are connected. A heat dissipation device 12 and a heat insulating device 13 are slidably engaged in the first sliding slot 14 and the second sliding slot 15 , respectively. Both sides of the front end of the submerged arc furnace body 1 are symmetrically fixed with a fixed installation plate 3, and the front end of the fixed installation plate 3 located on the outside is rotatably installed with a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com