Vibrating screen

A technology of vibrating screen and screen mesh, which is applied in the fields of filter screen, solid separation, chemical instruments and methods, etc., can solve the problems of waste of space materials, low work efficiency, and long time spent on screen mesh.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the embodiments.

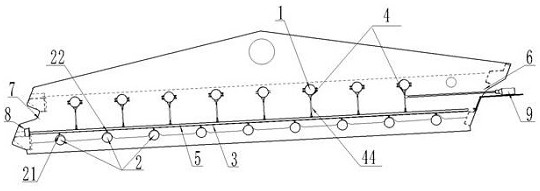

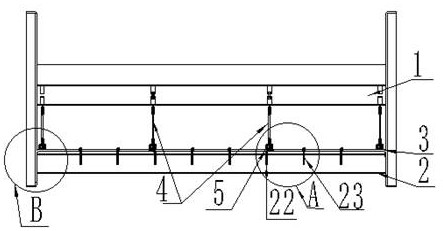

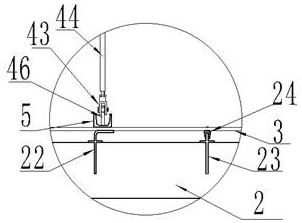

[0021] figure 1 It is a structural schematic diagram of the vibrating screen of the present invention, figure 2 for figure 1 left view of image 3 for figure 2 Enlarged view of A.

[0022] Such as figure 1 , 2 , 3, a vibrating screen of the present invention includes an upper sieve beam 1, a lower sieve beam 2, a screen 3 and a screen pressing mechanism 4. Figure 5 It is a structural schematic diagram of the connection between the screen pressing mechanism and the pressing rod, Figure 6 for Figure 5 left view of the , such as figure 2 , 5 , 6, the screen pressing mechanism 4 includes an upper connecting plate 41, a lower connecting plate 46, a normal thread Y-joint 42, a negative thread Y-joint 43 and a positive and negative thread screw 44. The upper connecting plate 41 is vertically fixed below the upper screen beam 1, and one end of the normal wire Y-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com