Rapid assembly type supporting bracket and supporting method

An assembled and fast technology, which is applied in shaft equipment, earthwork drilling, wellbore lining, etc., can solve problems such as difficult installation, affecting support efficiency, and complicated setting procedures, so as to improve installation efficiency, ensure tightness, and realize automatic The effect of the lock effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

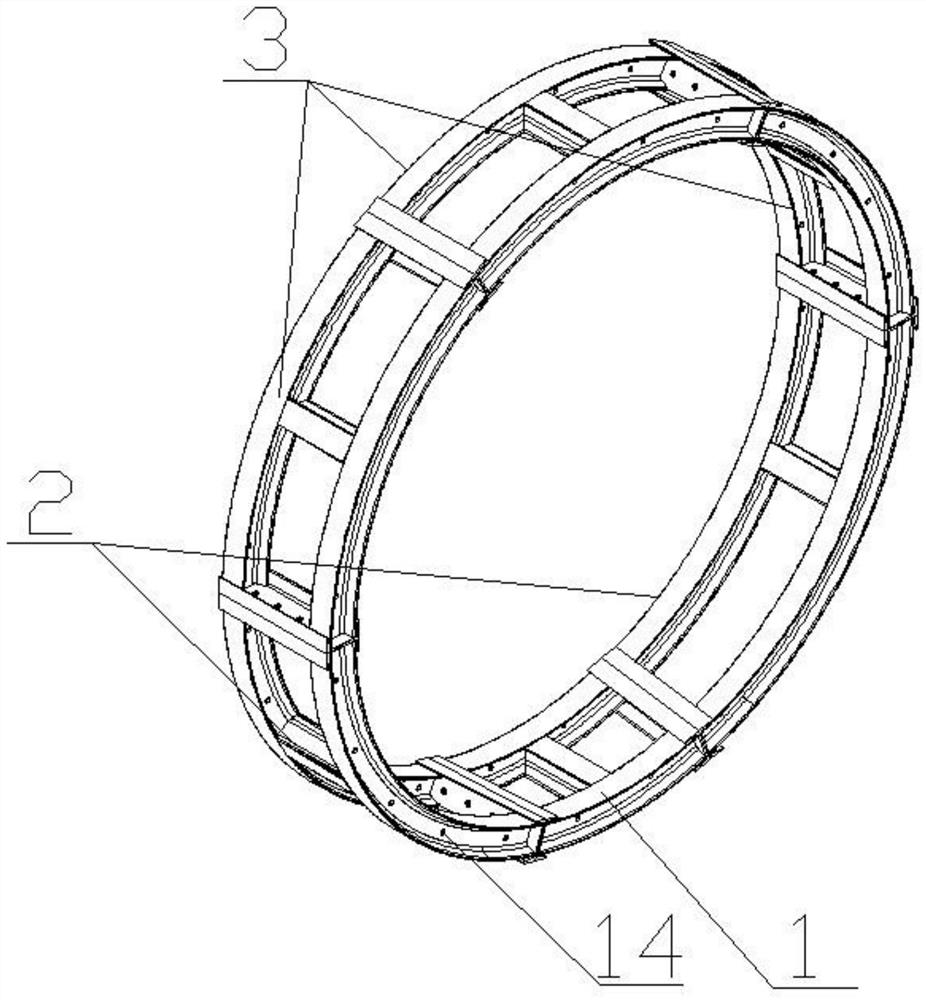

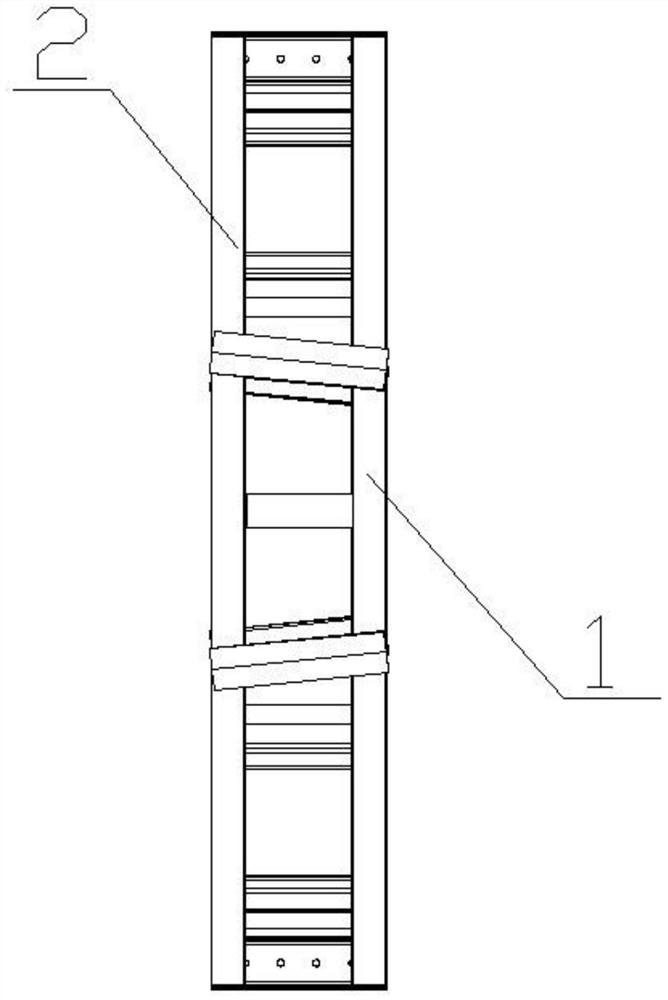

[0033] The quick-assemble support bracket includes several annular shield groups arranged in sequence on the inner wall of the tunnel; as figure 1 , figure 2 as shown, figure 1 It is a structural perspective view of the shield group; figure 2 It is a structural side view of the shield group. The shield group includes shield pieces, which are connected at the ends of adjacent shield pieces; the shield pieces include a shield frame 11 and a shield plate 12, and the shield plate 12 is fixedly arranged on the shield frame 11, the shield frame 11 is arranged in an arc-shaped structure, and the shield frame 11 is connected end to end by the shield plate 12 to form a closed ring.

[0034] The shield frame 11 is manufactured by welding I-beams, and the shield frame 11 includes at least two arc-shaped parts arranged in parallel and a reinforcement part connecting the arc-shaped parts, and the arc-shaped parts are bent by the I-beam system, thereby ensuring the stability of the ov...

Embodiment 2

[0045] A positioning component is also provided on the shield plate 12, and the positioning component is used to realize pre-positioning when adjacent shield pieces are installed.

[0046] Such as Figure 7 as shown Figure 7 It is a structural view of the positioning assembly; the positioning assembly includes a movable pin and a guide groove 15, the movable pin or the guide groove 15 is set on the shield plate 12, and the adjacent two shield plates The movable pin is correspondingly arranged with the guide groove 15 .

[0047] Such as image 3 and Figure 4 as shown, image 3 It is a structural view of the shield plate 12 provided with the positioning groove; Figure 4 It is a structural view of the shield plate 12 where the movable pin is set; generally, the guide groove 15 is extended along the width direction of the shield piece to facilitate the installation of the shield piece. When assembling the shield pieces, due to the need to assemble the shield pieces into a...

Embodiment 3

[0054] The support method of the quick-assembled support bracket of the present invention, specifically, includes the steps;

[0055] S1, connecting the standard blocks together to form an arc body;

[0056] S2, fixedly connecting one of the connecting blocks at both ends of the arc body, thereby forming an annular structure with a gap;

[0057] S3, placing the wedge block corresponding to the notch, and horizontally translating into the notch along the axial direction of the shield group, finally forming the annular shield group;

[0058] S4, by connecting the shield groups or arranging the shield groups at intervals to form the quick-assemble support bracket.

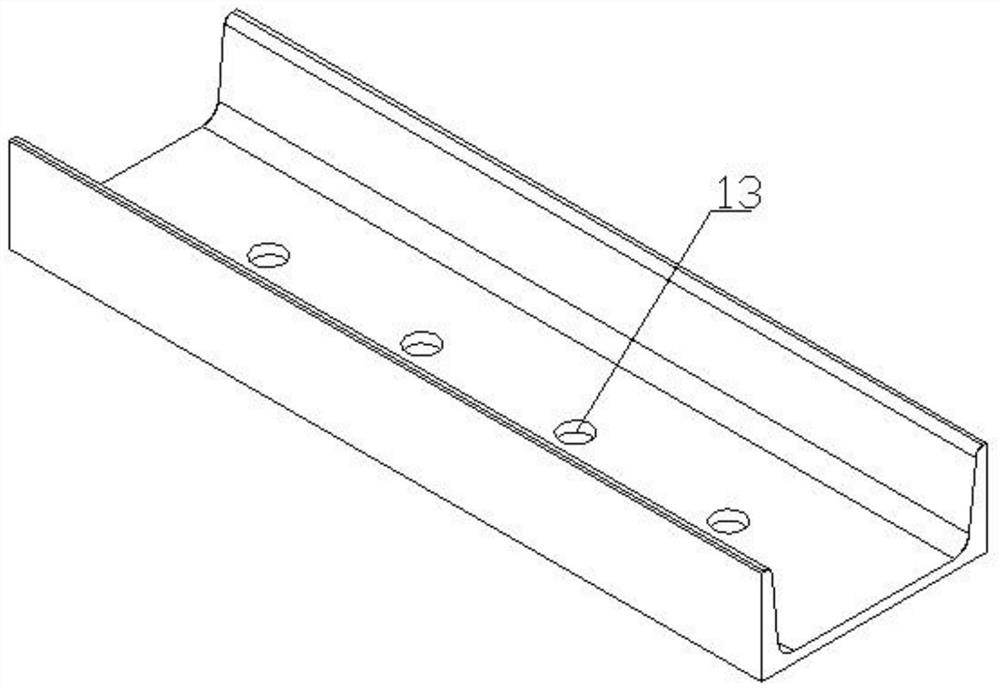

[0059] Generally, the connection between the standard blocks 3 and the connection between the connection block 2 and the standard block 3 all adopt bolt connection, that is, the connection block 2 and the connection block 2 are realized through the first mounting hole 13. The connection of standard block 3 is descri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com