Automatic glove strapping machine

An automatic strapping and glove technology, applied in the field of glove machines, can solve the problems of time-consuming and laborious, increased labor and production costs, and low efficiency of weaving gloves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

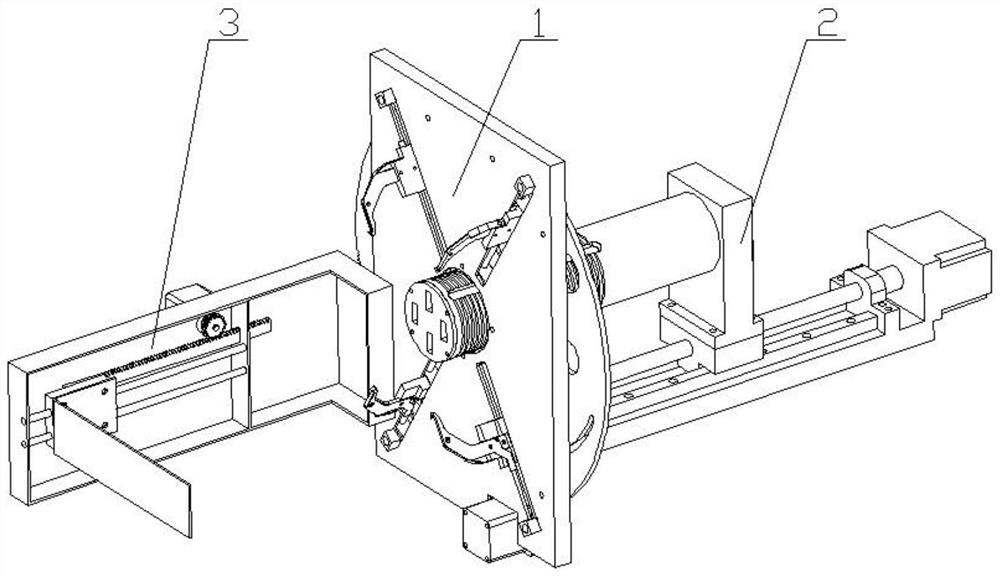

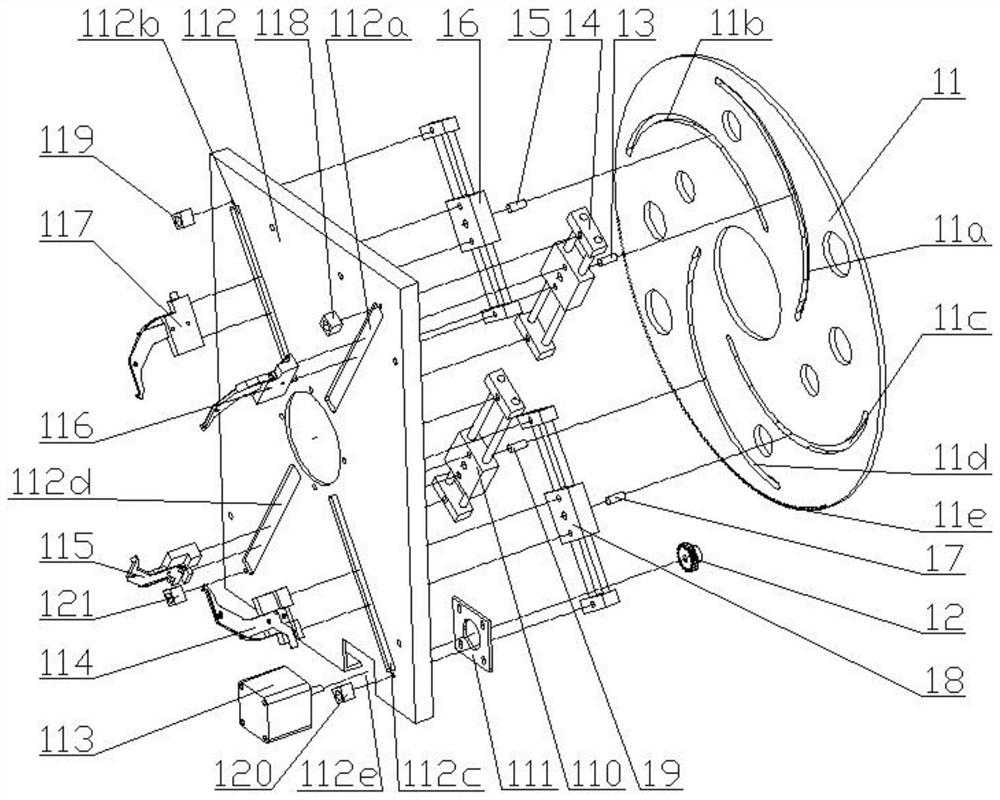

[0045] refer to Figure 1 to Figure 14 , this embodiment is used to install on the glove machine frame corresponding to the conveying device 5 receiving the glove stack 6, which includes a rubber band connecting and binding device 1, a rubber band placing device 2 and a glove pushing device 3;

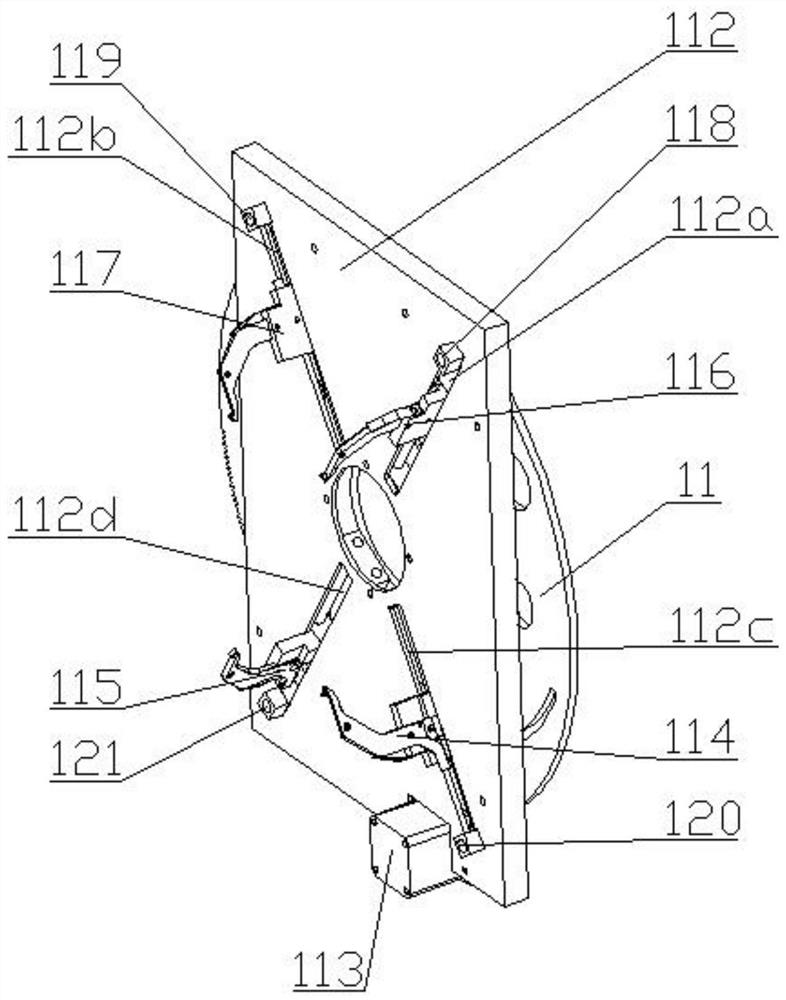

[0046] The rubber band connecting and binding device 1 is mainly composed of a sliding seat 112 which is vertically arranged and has a through hole and at least four hooking wire components with hook heads 41a. In this embodiment, there are four hooking wire components. Divided into the lower right hook assembly 114, the lower left hook assembly 115, the upper right hook assembly 116 and the upper left hook assembly 117, the sliding seat 112 is provided with the first chute 112a distributed in a divergent shape with the through hole as the center , the second chute 112b, the third chute 112c and the fourth chute 112d, the upper right hook line assembly 116, the upper left hook line ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com