Adhesive tape adsorption mechanism and adhesive tape pasting device

A technology of adsorption mechanism and gluing device, which is applied to structural parts, transportation and packaging, electrical components, etc., can solve the problems of high production cost and large space occupied by gluing mechanism, so as to simplify the structure, reduce production cost and maintenance cost , the effect of simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to facilitate the understanding of the present invention, the present invention will be described more fully below with reference to the associated drawings. Preferred embodiments of the invention are shown in the accompanying drawings. However, the present invention can be embodied in many different forms and is not limited to the embodiments described herein.

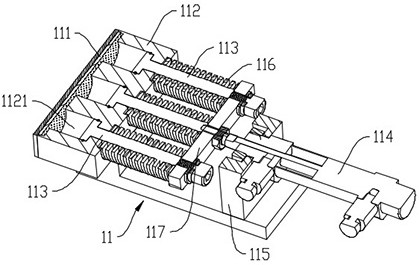

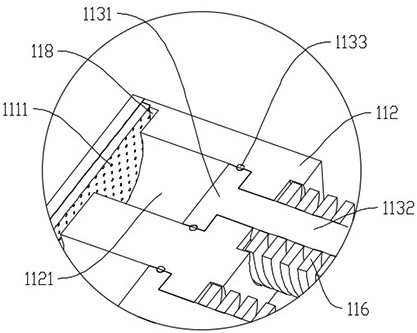

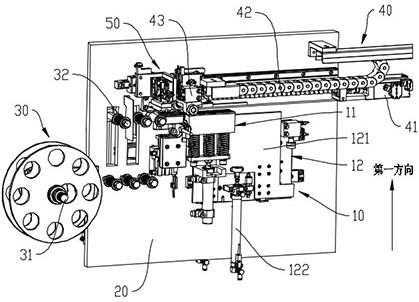

[0029] Such as figure 1 with figure 2 As shown, in a preferred embodiment, the adhesive tape adsorption mechanism 11 of the present invention mainly includes an adsorption plate 111 , a piston seat 112 , a piston member 113 , and a piston driving member 114 . Wherein, the adsorption plate 111 is in the shape of a flat plate, which is arranged on the feeding path of the adhesive tape. The adsorption plate 111 is provided with a number of suction holes 1111 arranged in an array. adhesive tape. The piston seat 112 is arranged on one side surface of the adsorption plate 111, and the periphery of one e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com