Small-sized self-starting cast-aluminum rotor permanent magnet synchronous motor punching sheet

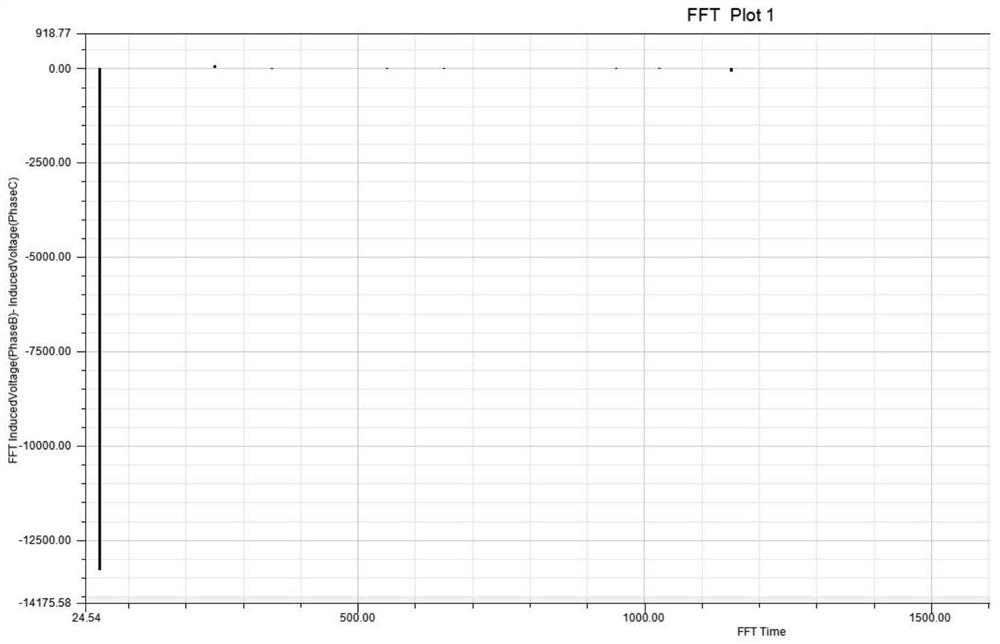

A technology for permanent magnet synchronous motors and cast aluminum rotors, applied in magnetic circuits, electrical components, electromechanical devices, etc., can solve the problems of increasing the risk of magnetic flux leakage, increasing costs, etc., to optimize the no-load back EMF waveform and reduce harmonics content, the effect of optimizing harmonic content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] For ease of understanding, combined here Figure 1-13 , the concrete structure and working mode of the present invention are further described as follows:

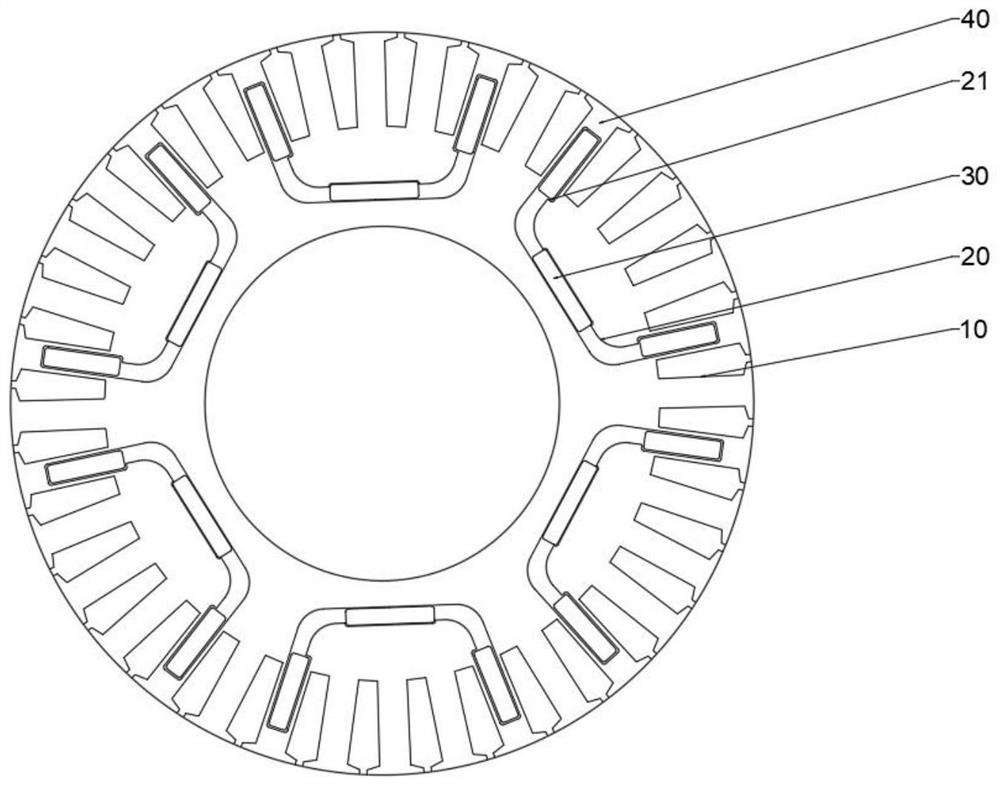

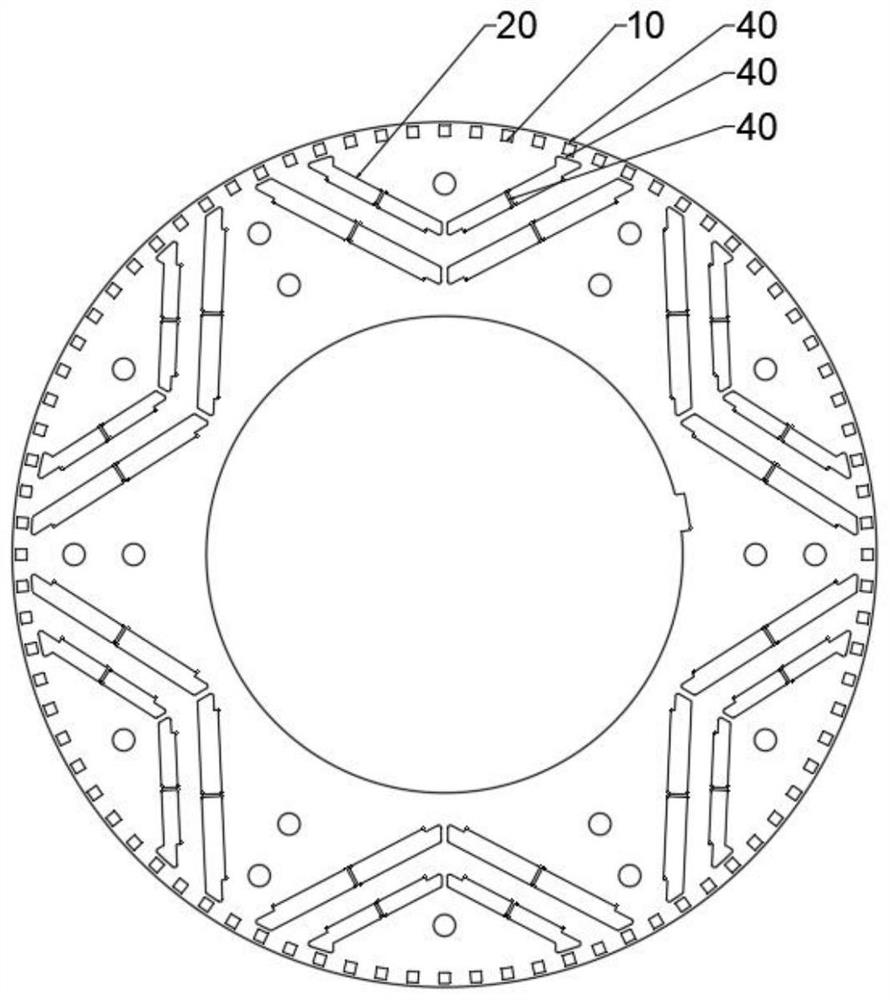

[0031] The specific structure of the present invention is as figure 1 As shown, including the rotor stamping, since the stamping of the present application is suitable for small self-starting permanent magnet motors, the outer diameter of the rotor stamping is 89.2mm.

[0032] The rotor punch is provided with six magnetic steel slots 20, and the six magnetic steel slots 20 are equidistantly arranged along the circumference of the rotor punch. The magnetic steel groove 20 is provided with two symmetrical bends, the two bends form obtuse angles and both obtuse angles face the outer edge of the rotor punching plate to form a three-section U-shaped structure. Three permanent magnets 30 are respectively arranged in the three sections of slots. Six magnetic steel slots 20 middle sections are arranged in a whole row to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com