Permanent magnet synchronous motor rotor structure applied to novel electric vehicle

A permanent magnet synchronous motor, electric vehicle technology, applied in electric vehicles, synchronous motors with static armatures and rotating magnets, magnetic circuit shape/style/structure, etc. content, radial force harmonic motor vibration and noise, etc., to achieve the effect of improving radial force wave, reducing harmonic content, and reducing vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

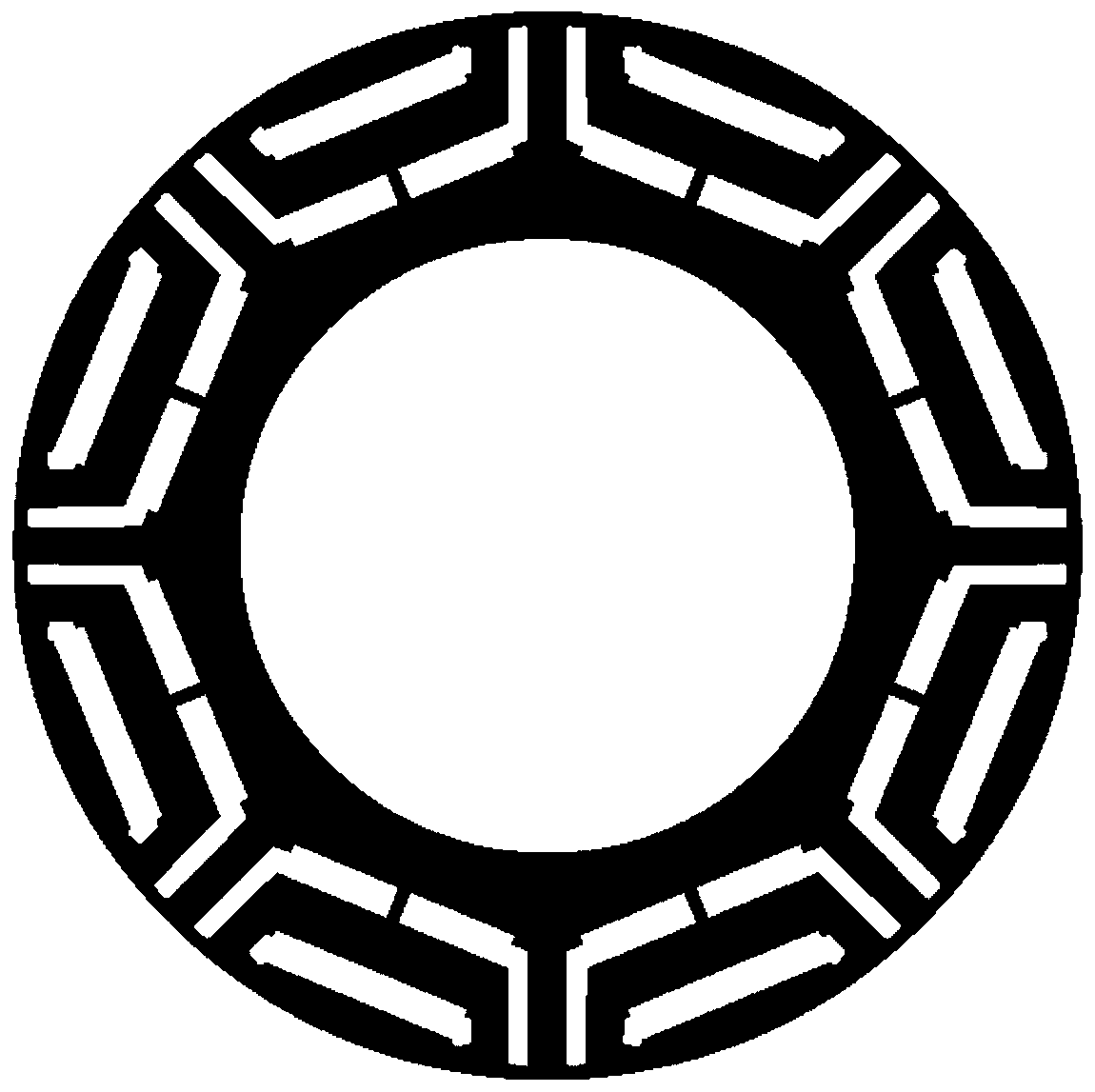

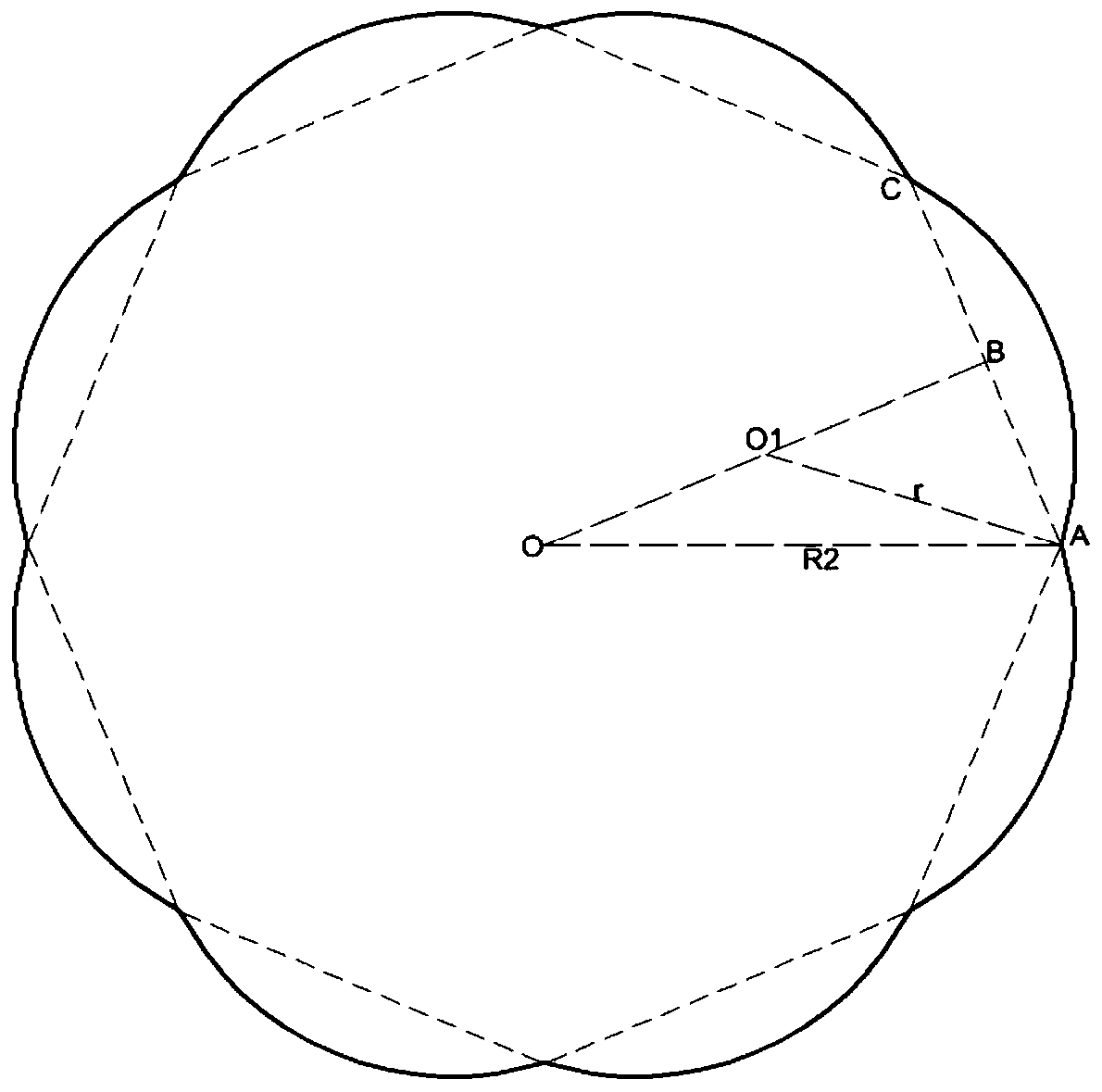

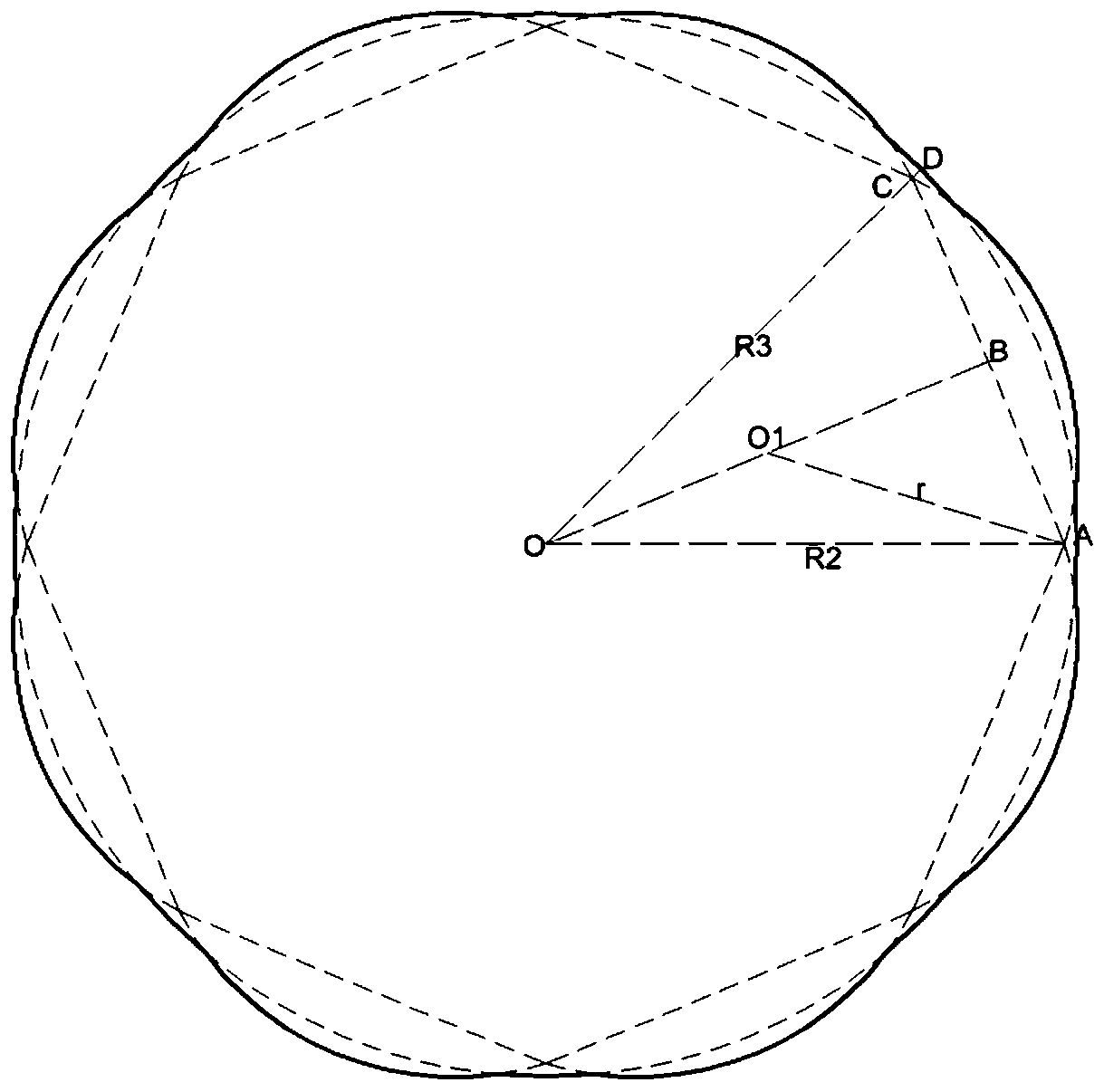

[0025] The present invention is according to 4 pairs of poles 48 slot permanent magnet synchronous motor rotor stampings (such as figure 1 ) to carry out innovative inventions, take the origin O of the original permanent magnet synchronous motor rotor punching sheet as the center to establish a regular octagon with a radius of R2, R2 figure 2 The graph shown. Make a circle with O as the center and R3 as the radius, and intersect the arc drawn above as image 3 , where R2 Figure 4 . Using the original permanent magnet synchronous motor stator structure and winding mode, R2 and R3 are used as parameters, and the air gap flux density distortion rate is used as a reference target to conduct parametric analysis with Maxwell, in which R2 and R3 are controlled to control the minimum and maximum air gaps respectively ,like Figure 5 shown. According to the inner diameter of the stator core in the original permanent magnet synchronous motor structure is 57mm, the optimal R2 here is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com