A camera device for industrial visual inspection

A technology of visual inspection and photographic device, applied in the field of visual inspection, can solve the problems of image capture of objects, affect inspection quality, limitation of photographic surface, etc., and achieve the effect of enhancing visual inspection quality, improving inspection quality, and improving inspection range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

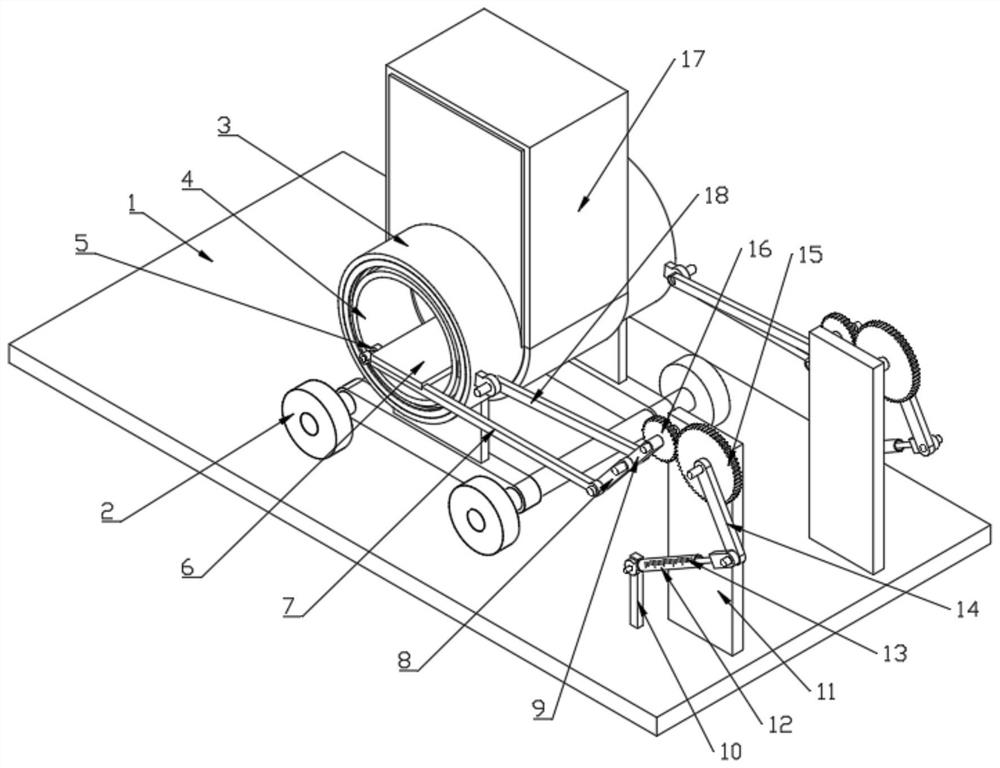

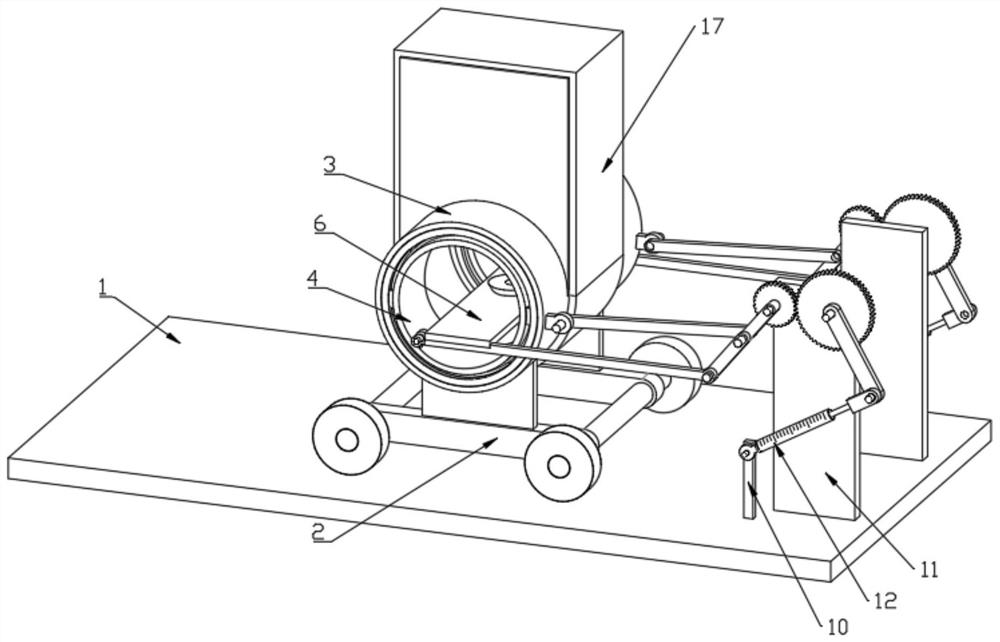

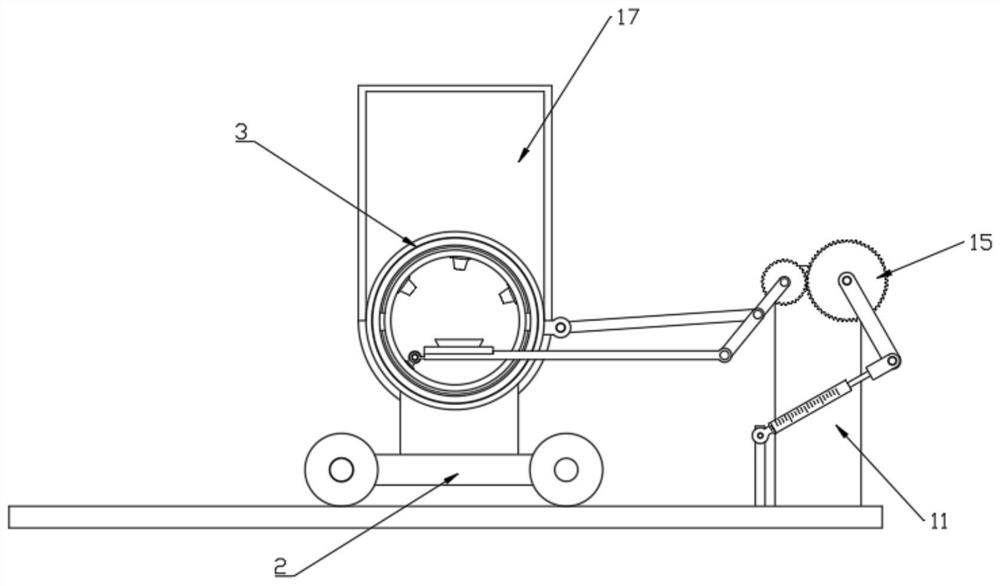

[0034]Embodiment 1, as a mode of the first drive mechanism, the first drive mechanism includes a first gear 15 and a first electric telescopic rod 12, the first gear 15 is rotatably installed on the upper part of the fixed plate 11, the first gear 15 and the first Two gears 16 meshing transmission, the first gear 15 is fixedly installed with the fourth connecting rod 14, the first electric telescopic rod 12 is installed on the bottom plate 1 through the rotation of the fixed rod 10, the first electric telescopic rod 12 is connected with the fourth through the telescopic rod One end of the rod 14 away from the first gear 15 is rotatably mounted.

[0035] By driving the first electric telescopic rod 12 to work, due to the length change of the first electric telescopic rod 12, the fourth connecting rod 14 and the first gear 15 can be further driven to rotate, and due to the meshing effect between the second gear 16 and the first gear 15 , can further drive the second gear 16 and ...

Embodiment 2

[0038] Embodiment 2, as another way of the first drive mechanism, further, the second drive mechanism for rotating the second gear 16 is connected to the fixed plate 11, and the second drive mechanism includes a second drive mechanism fixed on the fixed plate 11. The fixed part 31 on one side, the motor 32 is fixedly installed on the fixed part 31, the output shaft of the motor 32 passes through the fixed plate 11 and is connected with the first gear 15 in rotation, the outer wall of the output shaft of the motor 32 is fixed with a pointer 34, the pointer 34 A scale plate 33 is installed on the side wall of the fixed plate 11 where it is located.

[0039] The first gear 15 is driven by the motor 32 to rotate in a feeding manner, which is convenient for locking after rotation. At the same time, due to the cooperation of the pointer 34 and the dial 33, it is convenient to display the specific value of the rotation position of the first gear 15. Use the corresponding value One-to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com