Rotary disc tool clamp for assembling plunger pump cylinder body

A tooling fixture and plunger pump technology, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve problems such as low assembly efficiency, and achieve the effects of increasing assembly efficiency, increasing fixing effect, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

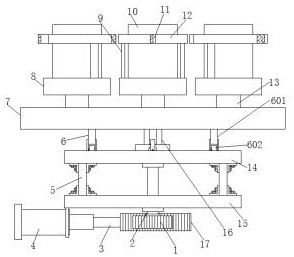

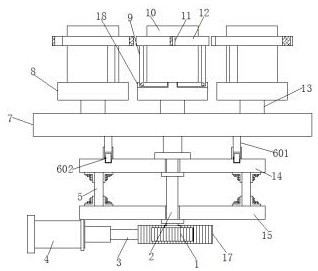

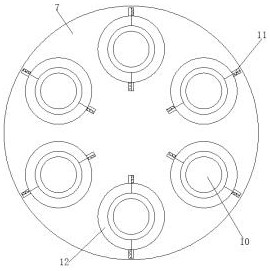

[0023] Example 1: See Figure 1-5 , a rotary disc tooling fixture for piston pump cylinder assembly, including a top plate 7, a rotating rod 16 is installed at the central position of the bottom end of the top plate 7, and a supporting plate 14 is installed on the bottom end of the rotating rod 16 through a bearing, and the supporting plate 14 The top is provided with a stabilizing structure 6;

[0024] The bottom of the support plate 14 is equipped with a fixed rod 5, and the bottom of the fixed rod 5 is equipped with a base plate 15, and one side of the bottom of the base plate 15 is equipped with a cylinder 4, and the output end of the cylinder 4 is connected with a pneumatic telescopic rod 3, and the pneumatic telescopic One end of the rod 3 is equipped with a toothed plate 17, the central position of the bottom end of the base plate 15 is provided with a connecting rod 2, and the bottom end of the connecting rod 2 is equipped with a driven circular gear 1, and the top of ...

Embodiment 2

[0030] Embodiment 2: The stable structure 6 includes a mounting rod 601, a rolling wheel 602 and a chute 603, the chute 603 is opened on the top of the support plate 14, the bottom end of the top plate 7 is equipped with a mounting rod 601, and the bottom end of the mounting rod 601 passes through The bearing is equipped with a rolling wheel 602;

[0031] The number of mounting rods 601 is four, and the four mounting rods 601 are symmetrical about the center of the top plate 7;

[0032] The shape of the chute 603 is circular, and the bottom end of the scroll wheel 602 runs through the top of the chute 603 and extends to the inside of the chute 603;

[0033] Specifically, as figure 1 , figure 2 with Figure 4 As shown, through the presence of the installation rod 601, when the device is assembled and subjected to pressure, in order to maintain the stability of the device, the installation rod 601 can be used to share the pressure on the rotation rod 16, so that the rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com