Locking structure for vehicle-mounted electronic equipment

A technology of locking structure and on-board electronics, which is applied in vehicle components, transportation and packaging, etc., can solve the problems of unstable equipment assembly, inconvenient switching assembly, single locking function of equipment, etc., and achieve the effect of convenient switching and easy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

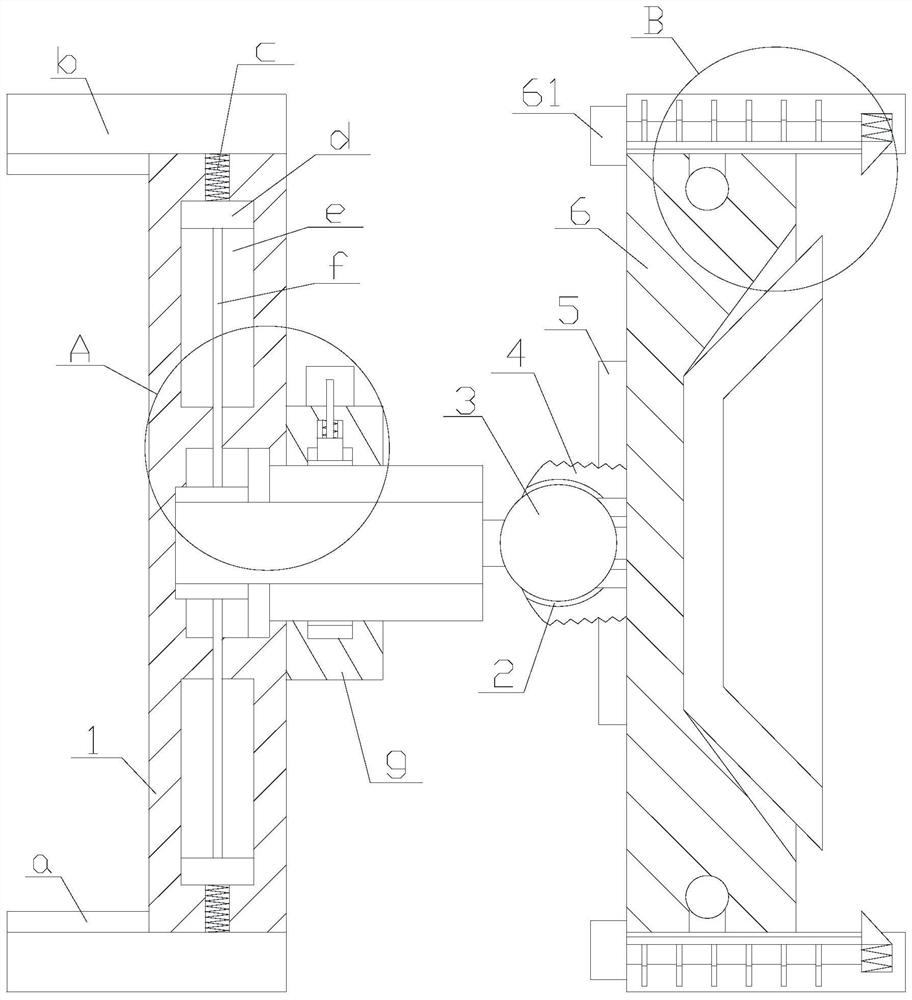

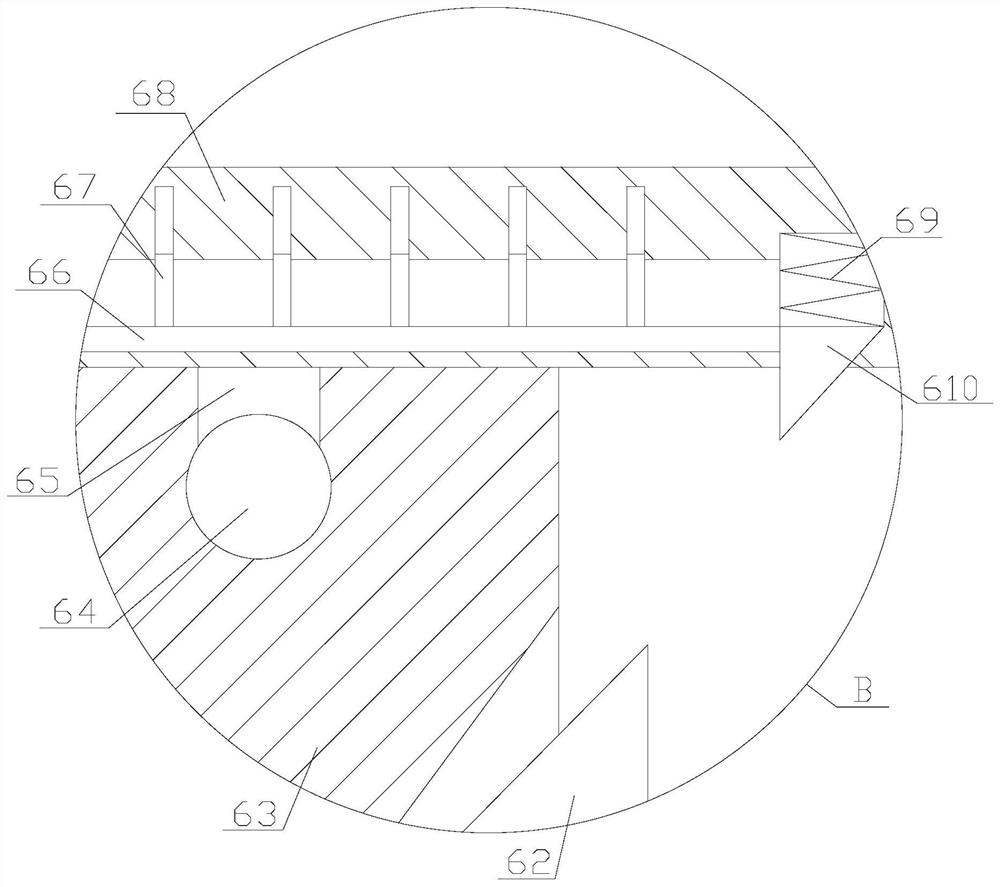

[0025] see Figure 1-Figure 5 , the present invention provides a locking structure for vehicle-mounted electronic equipment: the structure includes an equipment assembly plate 1, an anti-skid pad 2, a butt ball 3, a threaded strip 4, a locking ring 5, and a locking assembly plate 6. After the equipment assembly plate 1 The end is fixedly connected with a butt ball 3, the left side of the threaded bar 4 is covered and socketed on the butt ball 3, the right end of the threaded bar 4 is fixedly connected with the left end of the locking assembly plate 6, and the threaded bar 4 is connected with the butt ball 3 An anti-slip pad 2 is provided at the place, and a locking ring 5 is covered on the threaded strip 4, and the locking ring 5 is threadedly connected with the threaded strip 4;

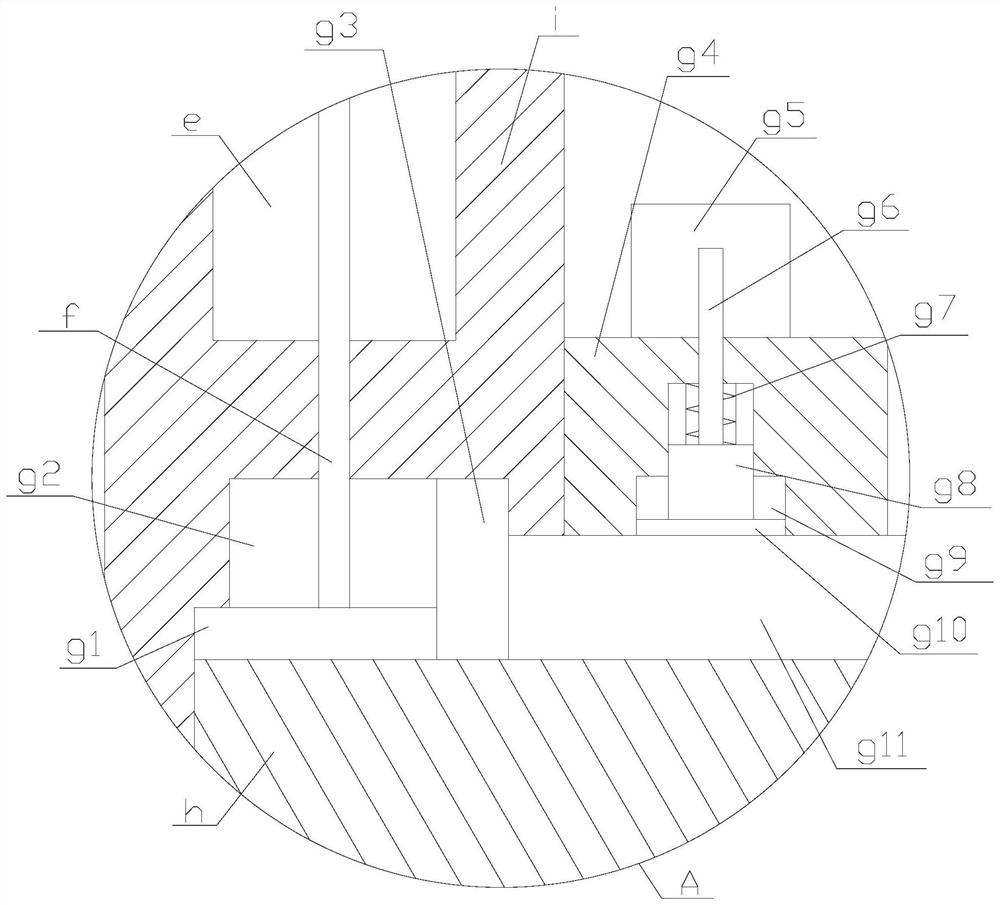

[0026] The equipment assembly plate 1 includes an assembly backing plate a, an assembly clamp b, a tension spring c, a spring assembly plate d, a movable groove e, a pull cord f, a locking device g,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com