Preparation method of water-resistant mosquito and fly sticking and catching net

A water-resistant, mosquito-fly technology, applied in the field of materials, can solve problems such as failure of adhesion when exposed to water, and achieve the effect of simple formula and preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

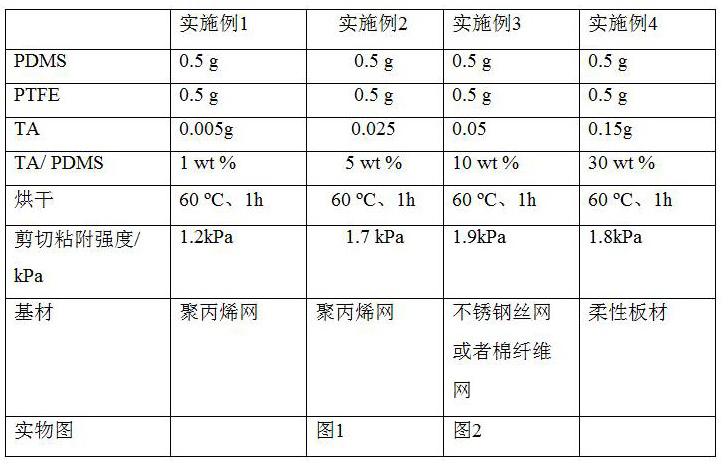

[0025] The preparation method of embodiment 1 is as follows:

[0026] 1. Weigh 0.5 g of liquid polydimethylsiloxane (PDMS), 0.5 g of solid polytetrafluoroethylene (PTFE) micron particles and 0.005 g of tannic acid (TA) (TA accounts for 1% of the mass of PDMS) in In a 50ml beaker, stir carefully with a small stainless steel wire spatula until a uniform white gel-like mixture (PDMS / PTFE / TA) is obtained. The shear adhesion strength was 1.2 kPa.

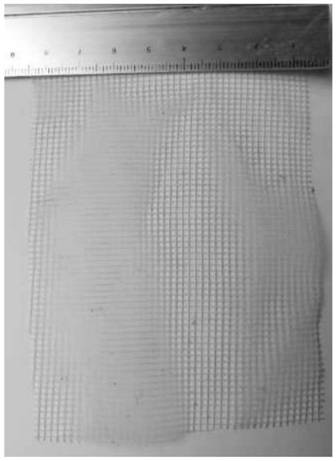

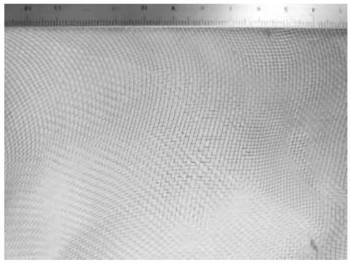

[0027] 2. The white glue-like mixture PDMS / PTFE / TA is evenly coated on the front and back sides of the polypropylene mesh to keep the mesh from being blocked. Polypropylene mesh is commercially available with a mesh diameter of approximately 1 mm.

[0028] 3. Place the polypropylene mesh coated with the white paste mixture in a blast drying oven to heat at 60ºC for 1 hour. After the end, it is taken out from the blast drying oven, and the target product water-resistant sticky mosquito polypropylene net is obtained.

Embodiment 4

[0029] Embodiment 4 performance investigation

[0030] Used under natural conditions, the obtained sticky mosquito glue is a viscous liquid, which has the characteristics of not flowing at room temperature, and is odorless, non-toxic, non-corrosive, and can resist sunlight and weathering. Conforms to the characteristics of general sticky mosquito glue.

[0031] The sticky mosquito glue obtained in Examples 1, 2, and 3 were completely placed in water and soaked at room temperature for a week, and the shear tensile strength was measured again to be 2.6kPa, 3.9kPa, and 3.6kPa, and the adhesive strength did not decrease, indicating that this product Resistant to water immersion. Compared with before immersion, the adhesive strength increased, which may be due to the partial polymerization of PDMS itself.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap