Fabricated building structure

A building structure, prefabricated technology, applied in building construction, construction, covering/lining, etc., can solve problems such as difficult to remove tiles, and achieve the effect of improving stability and simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following is attached Figure 1-6 The application is described in further detail.

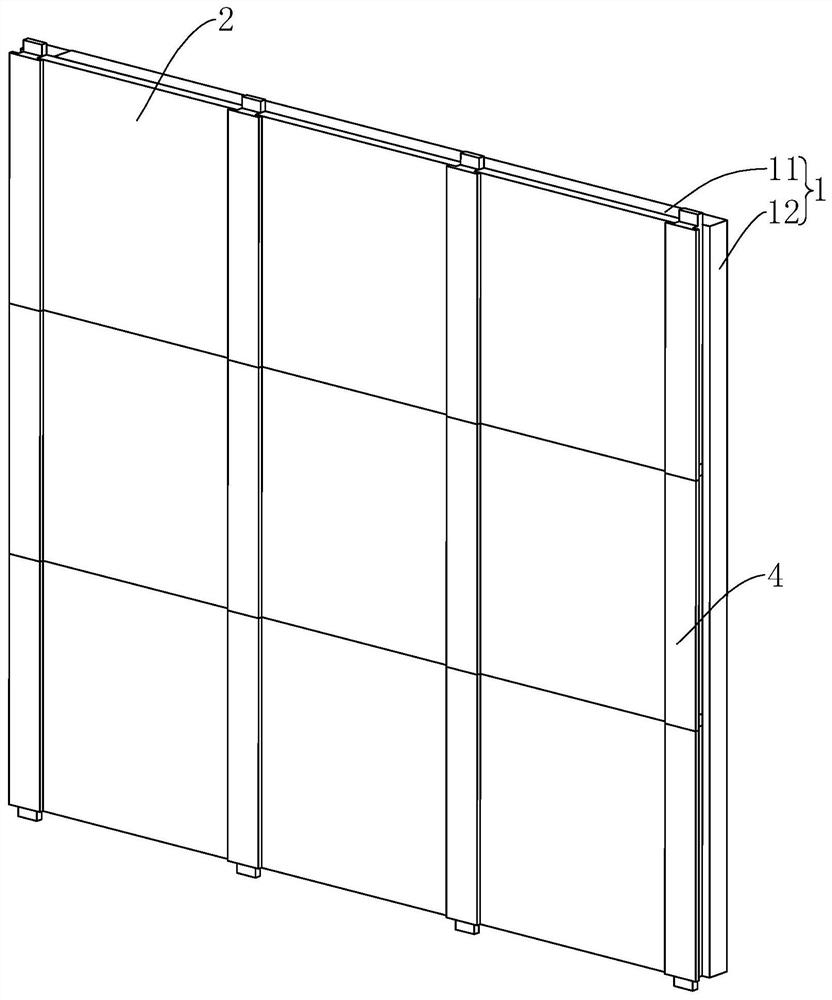

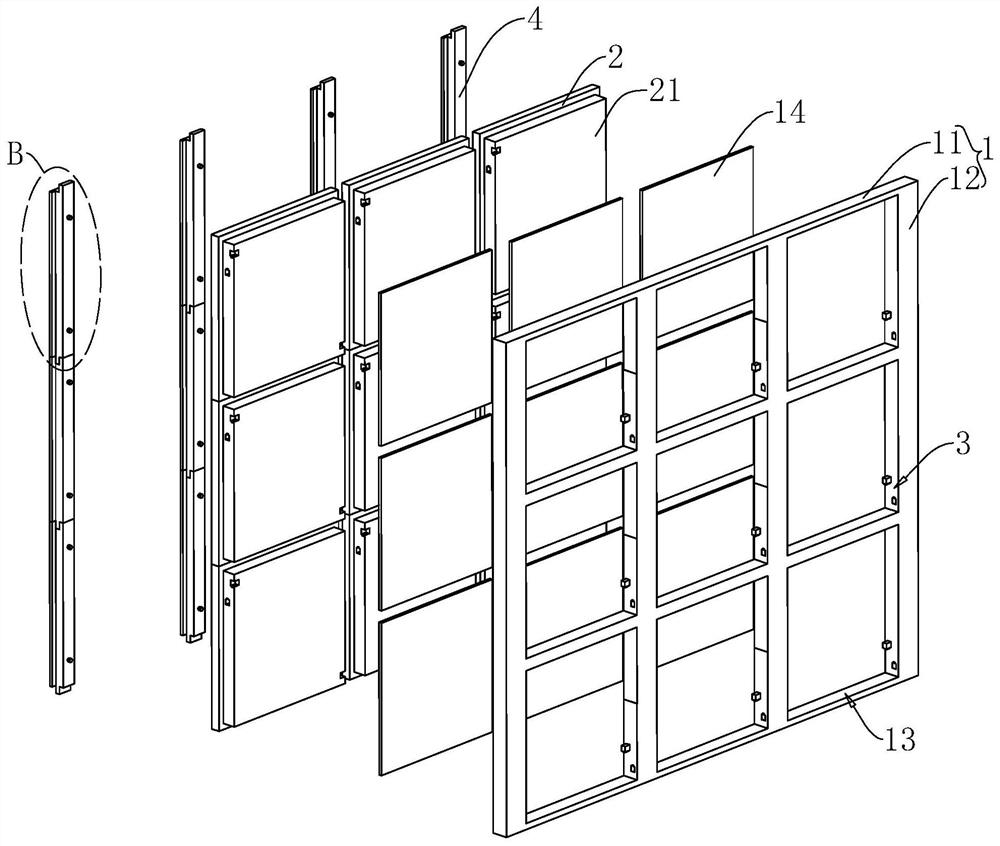

[0042] The embodiment of the present application discloses a prefabricated building structure. refer to figure 1 , figure 2 The prefabricated building structure includes a keel 1 for fixing on the facade, a plurality of ceramic tile bodies 2 , a plurality of connecting mechanisms 3 arranged on the keel 1 and a plurality of sealing strips 4 arranged on the keel 1 .

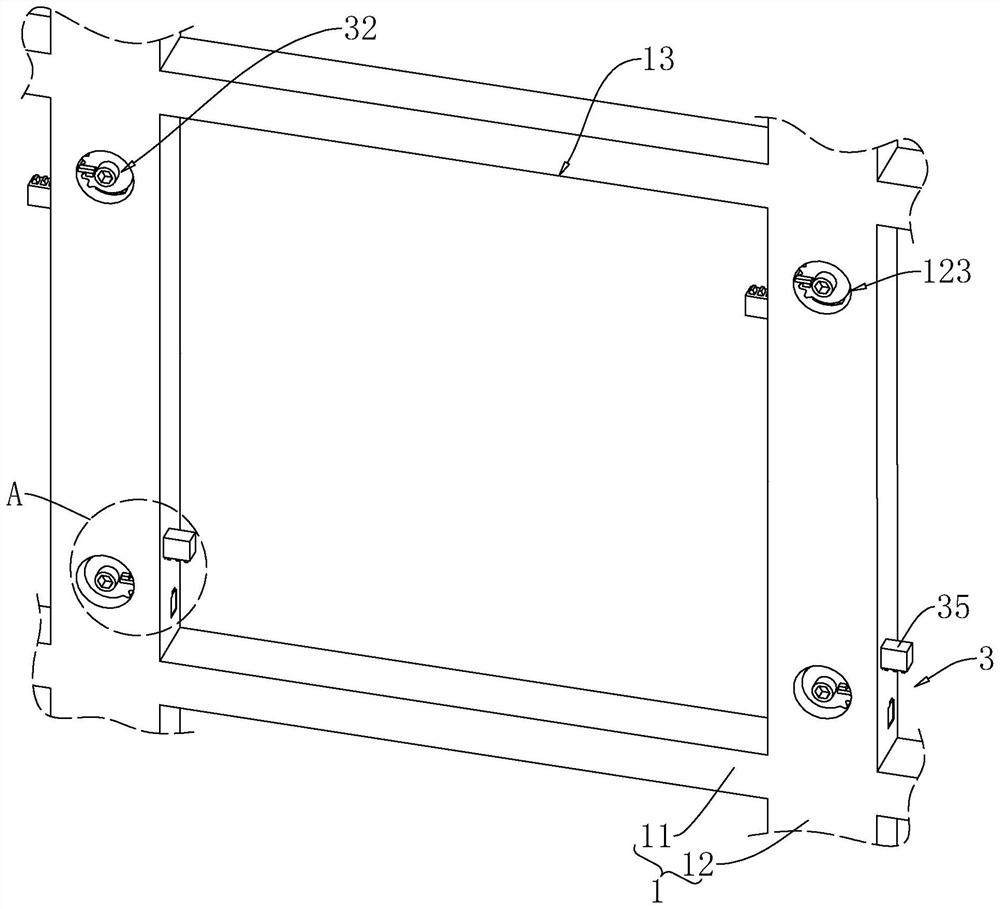

[0043] refer to figure 2 , image 3 The keel 1 includes a plurality of beams 11 and a plurality of longitudinal beams 12, the beams 11 and the longitudinal beams 12 are arranged in a "well" shape to form a plurality of connecting holes 13, and the beams 11 and the longitudinal beams 12 are welded and fixed. Each beam 11 extends horizontally, and each longitudinal beam 12 extends vertically. A thermal insulation pad 14 is placed in the connection hole 13, and the thermal insulation pad 14 is a rock wool thermal insul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com