Wire drawing die box

A wire drawing die and die technology, which is used in wire drawing dies and other directions to achieve efficient temperature control and heat conduction optimization, easy disassembly and assembly, and efficient heat conduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

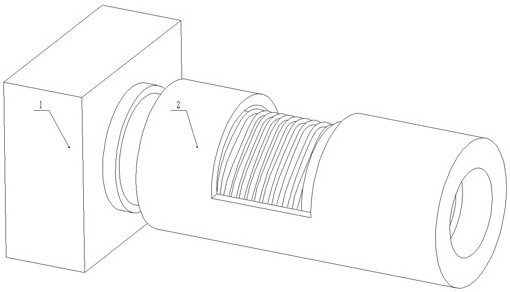

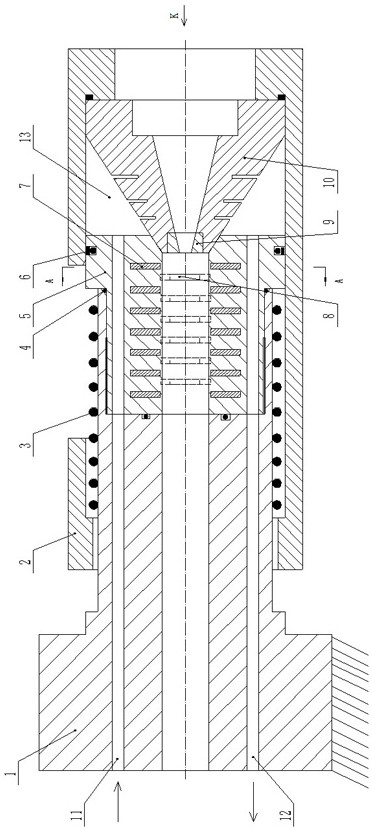

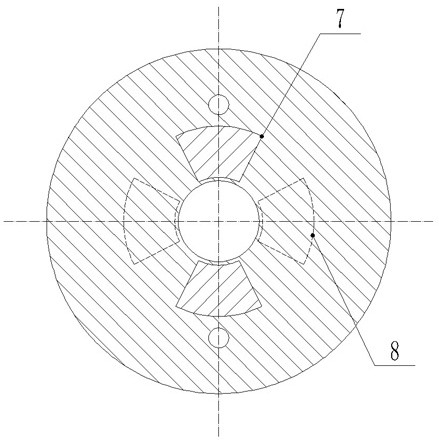

[0022] Such as Figure 1-5 As shown, a wire drawing die box includes: a guide shaft 1, an installation cylinder 2, a spring 3, a connecting cylinder 5, a PTC heating element 7, a semiconductor refrigeration sheet 8, a wire drawing die 9, and a cone 10, wherein the guide shaft 1. The connecting cylinders 5 are respectively provided with axial guide through holes, the left end of the guide shaft 1 is a fixed end, the right end of the guide shaft 1 is provided with a threaded inner hole, one end of the connecting cylinder 5 is provided with an external thread, and the other end is provided with an outer ring platform, the outer circle of the outer ring platform is provided with a sealing groove for installing the gray ring 6, the external thread end of the connecting cylinder 5 is screwed into the threaded inner hole of the guide shaft 1, and the inner hole at the right end of the guide shaft 1 is chamfered, and the connection The cylinder 5 and the guide shaft 1 are chamfered to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com