Convenient-to-operate well climbing type material distributing device

A material distributing device and convenient operation technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems that the material distributing machine is easy to shake, inconveniently fixed inside the shaft, and affects the normal operation of the material distributing machine, so as to achieve convenient operation, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

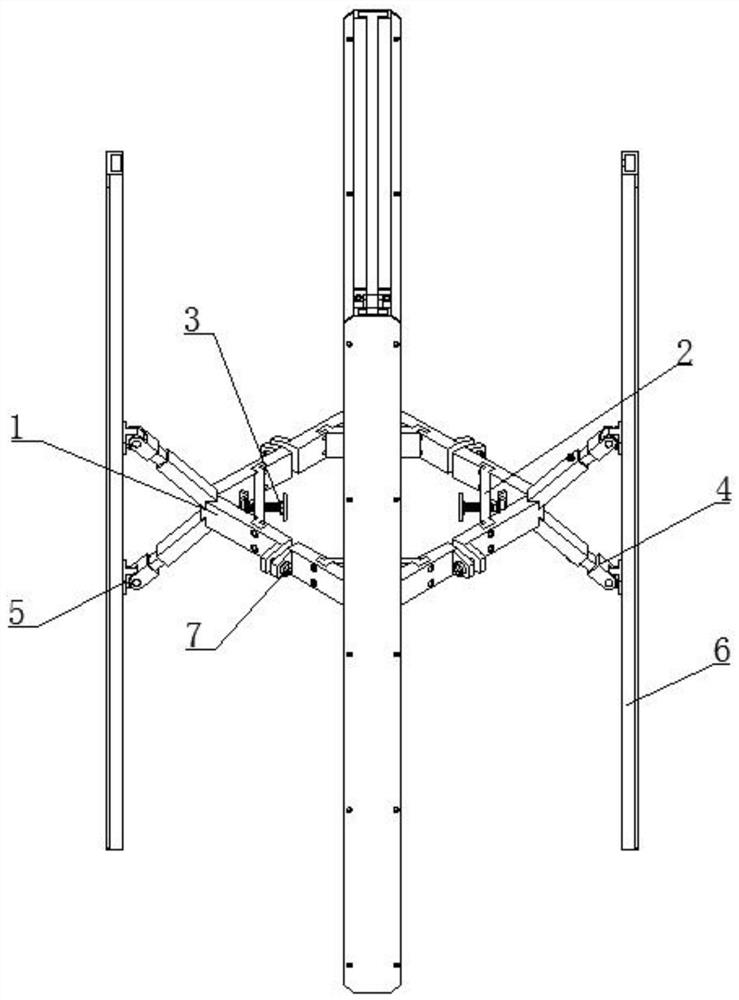

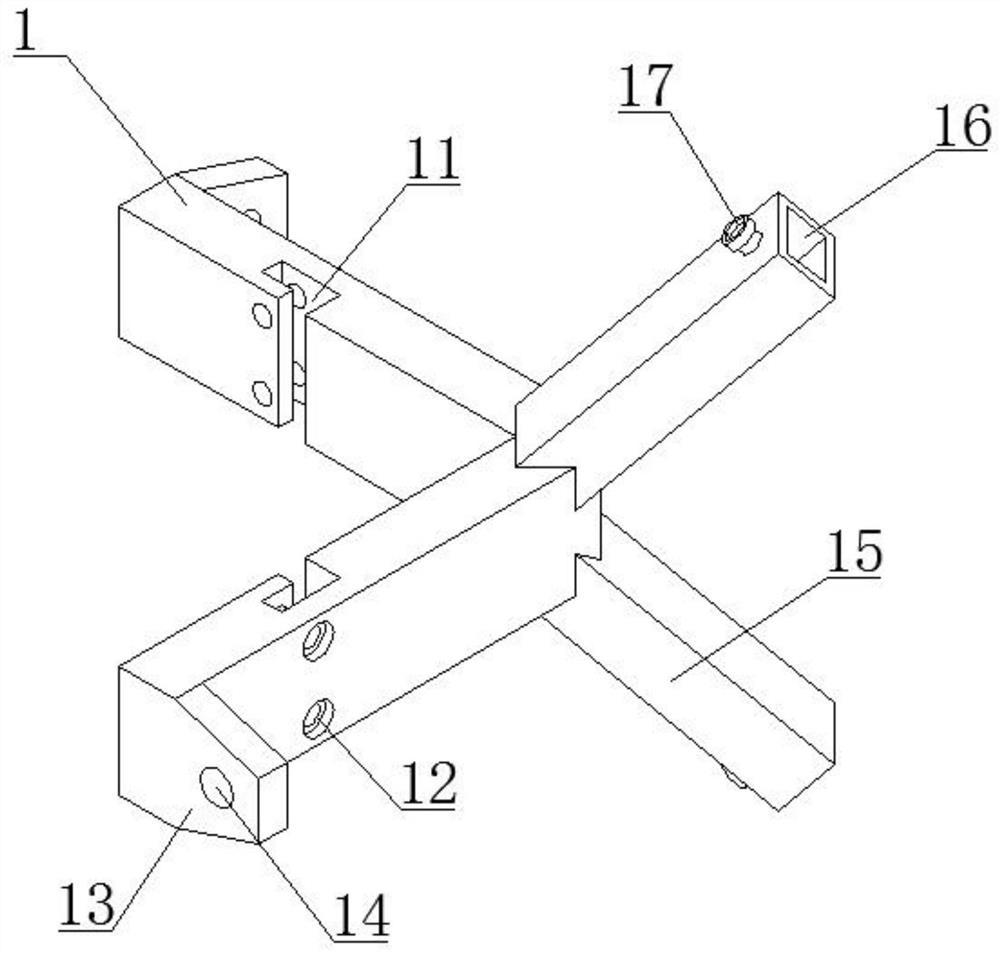

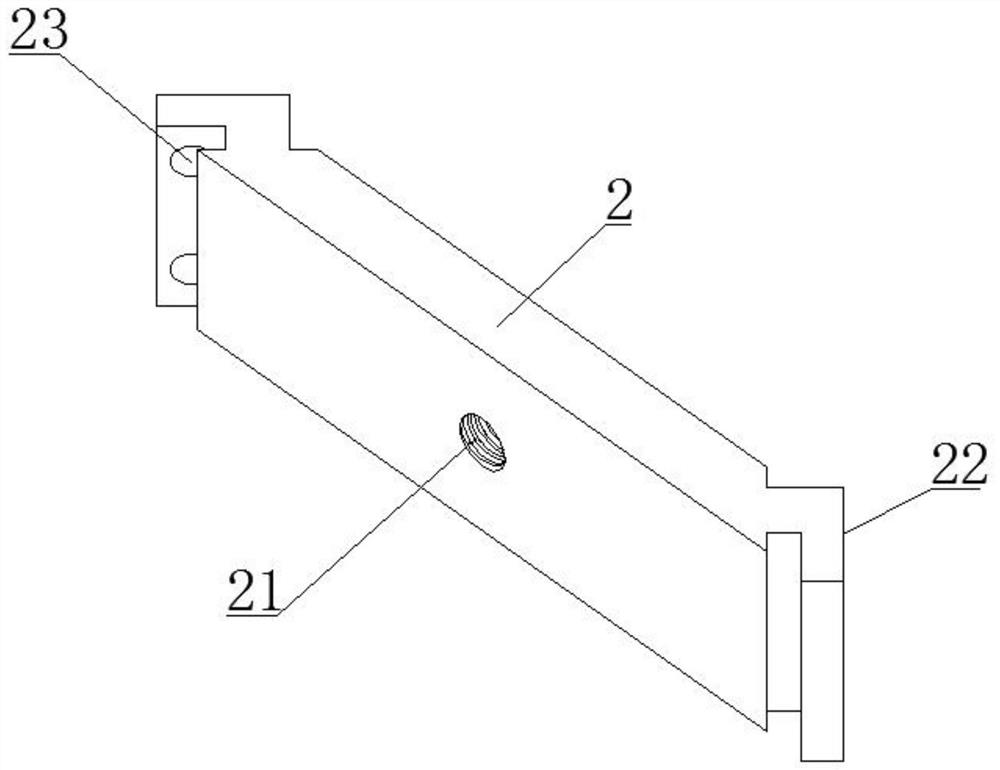

[0024] Example: refer to figure 1 Shown: a convenient operation hoistway climbing type material distribution device, including the material distribution machine, the four corners of the standard section of the lower part of the material distribution machine are equipped with chucks 1, and every two adjacent chucks 1 are connected by connecting bolts 7 are connected together, and the inner side of each chuck 1 is provided with a chuck rod 2, the chuck rod 2 and the chuck 1 are snapped together, and the middle part of the chuck rod 2 is threaded with a positioning head 3, and the outer corner of the chuck 1 is inclined Connecting rod 4 is connected upwards and inclined downwards, the tail end of connecting rod 4 is connected with adapter 5, the tail end of adapter 5 is connected with guide rail 6, adapter 5 and guide rail 6 are slidably connected together, and guide rail 6 is installed in the hoistway On the side wall; the concrete distribution machine is convenient for distribu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com