Thrust conversion mechanism

A technology of converting mechanism and thrust, applied in mechanical equipment, instruments, electrical and digital data processing, etc., can solve problems such as damage to the continuity of the picture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, an example of the thrust converting mechanism to which the present invention is applied will be described in detail with reference to the drawings. In addition, in the following description, the same reference numerals are used for the same or substantially the same configurations, elements, and the like, and overlapping descriptions are appropriately omitted.

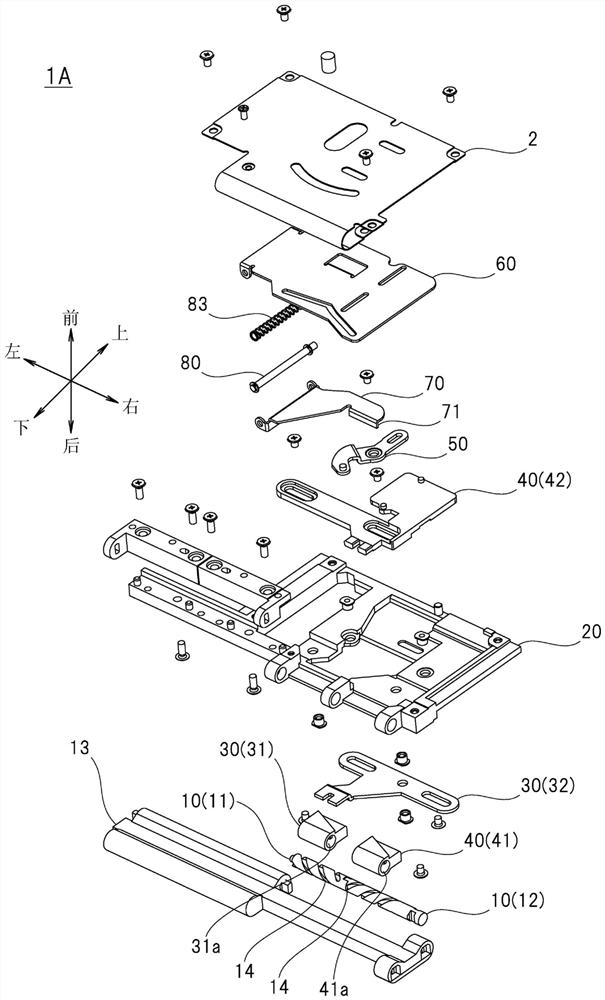

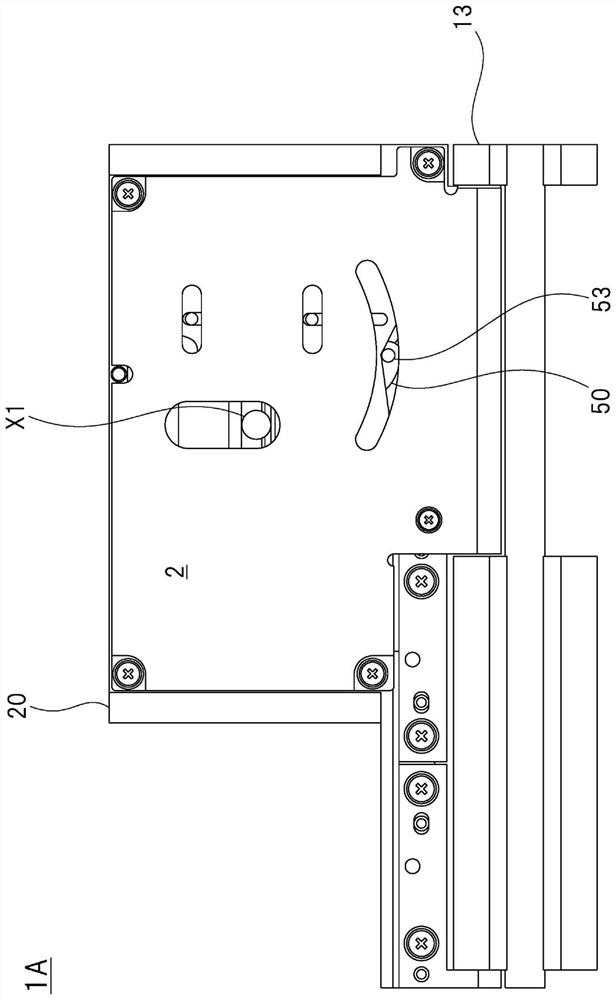

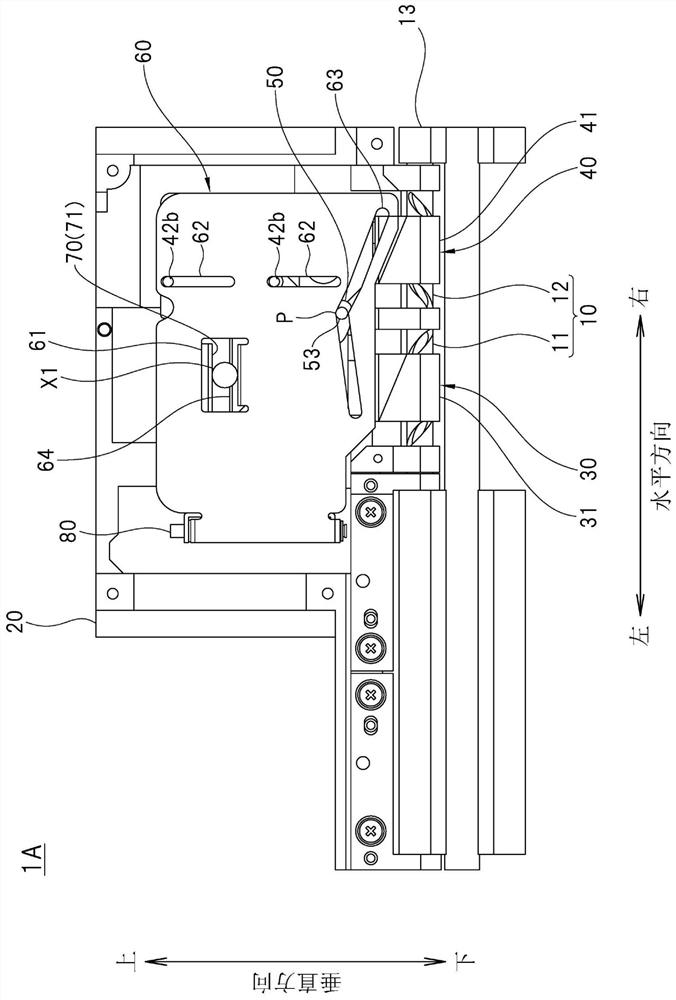

[0031] Such as figure 1 As shown, the thrust conversion mechanism 1A of this embodiment has a shaft 10, a housing 20, a first linear motion member 30, a second linear motion member 40, a rotary member 50, a drive member 60, and a buffer member 70. These constituent elements are as follows: Figure 2 ~ Figure 6 combined as shown. in addition, figure 2 It is a front view of the thrust converting mechanism 1A. In addition, in Figure 3 ~ Figure 6 In each of the drawings, in order to illustrate the internal structure of the thrust conversion mechanism 1A, some components are omitted. For example, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com