Non-contact proximity switch and valve position indicating system

A non-contact, proximity switch technology, applied in the direction of electric switches, contacts, electrical components, etc., can solve the problems of proximity switch misoperation, false signal, etc., to avoid contact misoperation, enhance anti-vibration performance, and improve stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

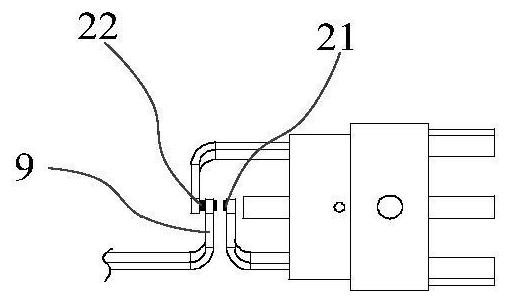

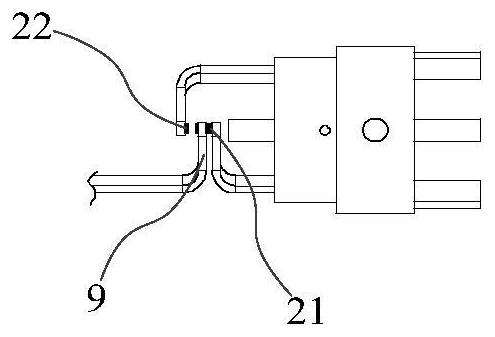

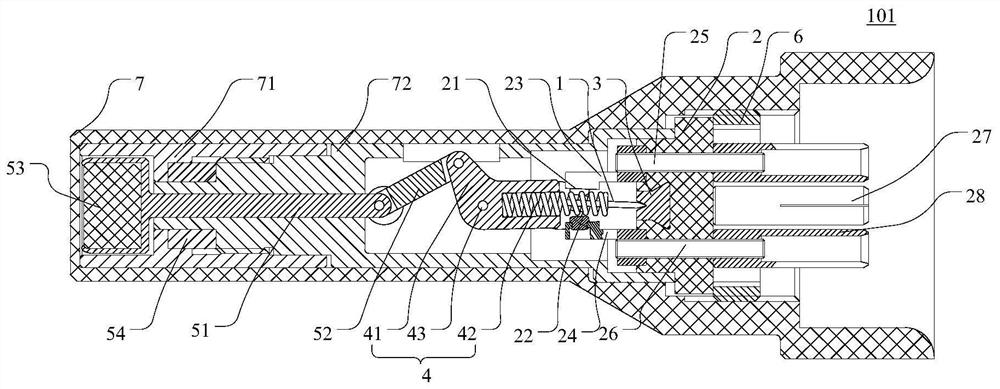

[0033] figure 1 It is a structural schematic diagram of the open state of the proximity switch of the related technology; figure 2 It is a structural schematic diagram of a closed state of a proximity switch in the related art. Such as figure 1 and figure 2 As shown, the existing proximity switch includes a housing, a first stationary contact 21 and a second stationary contact 22 fixedly arranged on the housing, and a movable contact arm 9 . The movable contact arm 9 is located between the first stationary contact 21 and the second stationary contact 22 . Two movable contacts are respectively arranged on the left and right sides of the free end of the movable contact arm 9 . The movable contact arm 9 contacts the first static contact 21 when it moves to the right end, and contacts the second static contact 22 when it moves to the left end. However, when the movable contact arm 9 of the proximity switch vibrates in a vibrating environment, resulting in non-stop switching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com