Method for pouring glue into capacitive water level sensor

A water level sensor and capacitive technology, which is applied in the direction of liquid level indicators for physical variable measurement, can solve the problems of increasing the production cost of the circuit board and the small effective use area of the circuit board, so as to increase the effective use area and reduce the production cost , enhance the effect of stress resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

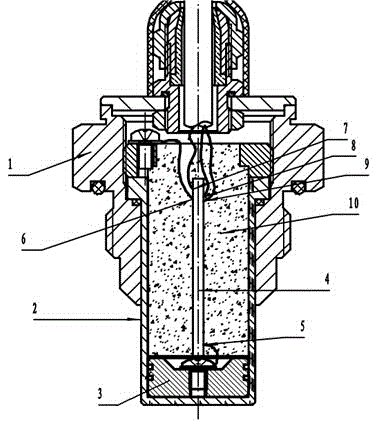

[0021] refer to figure 1 , this embodiment includes the following steps:

[0022] S1: a circuit board installation cavity is provided in the isolation sleeve 2 of the capacitive water level sensor;

[0023] S2: put the circuit board 4 carrying the signal acquisition and conditioning circuit into the circuit board installation cavity along the vertical direction;

[0024] S3: Connect the pad P1 of the circuit board 4 to the copper pad 3 that senses the original capacitance data with the first high-temperature wire 5; solder the pad P2 of the circuit board 4 to the joint 1 with the second high-temperature wire 6; Connect the pad V+ of the circuit board 4 to the power line 7 of the capacitive water level sensor by soldering; connect the pad V- of the circuit board 4 to the ground wire 8 of the capacitive water level sensor; Vout is so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com