Middle-arranged magnetic steel magnetic circuit structure with inclined surface contact

A technology of magnetic steel and slope, applied in the direction of circuits, electromagnetic relays, electromagnetic relay details, etc., can solve the problems of poor anti-vibration performance, small contact projection area, small electromagnetic attraction, etc., to achieve increased anti-vibration performance and improved vibration performance Index, the effect of meeting the requirements of the vibration index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions provided by the present invention will be further described in detail in conjunction with specific embodiments and accompanying drawings.

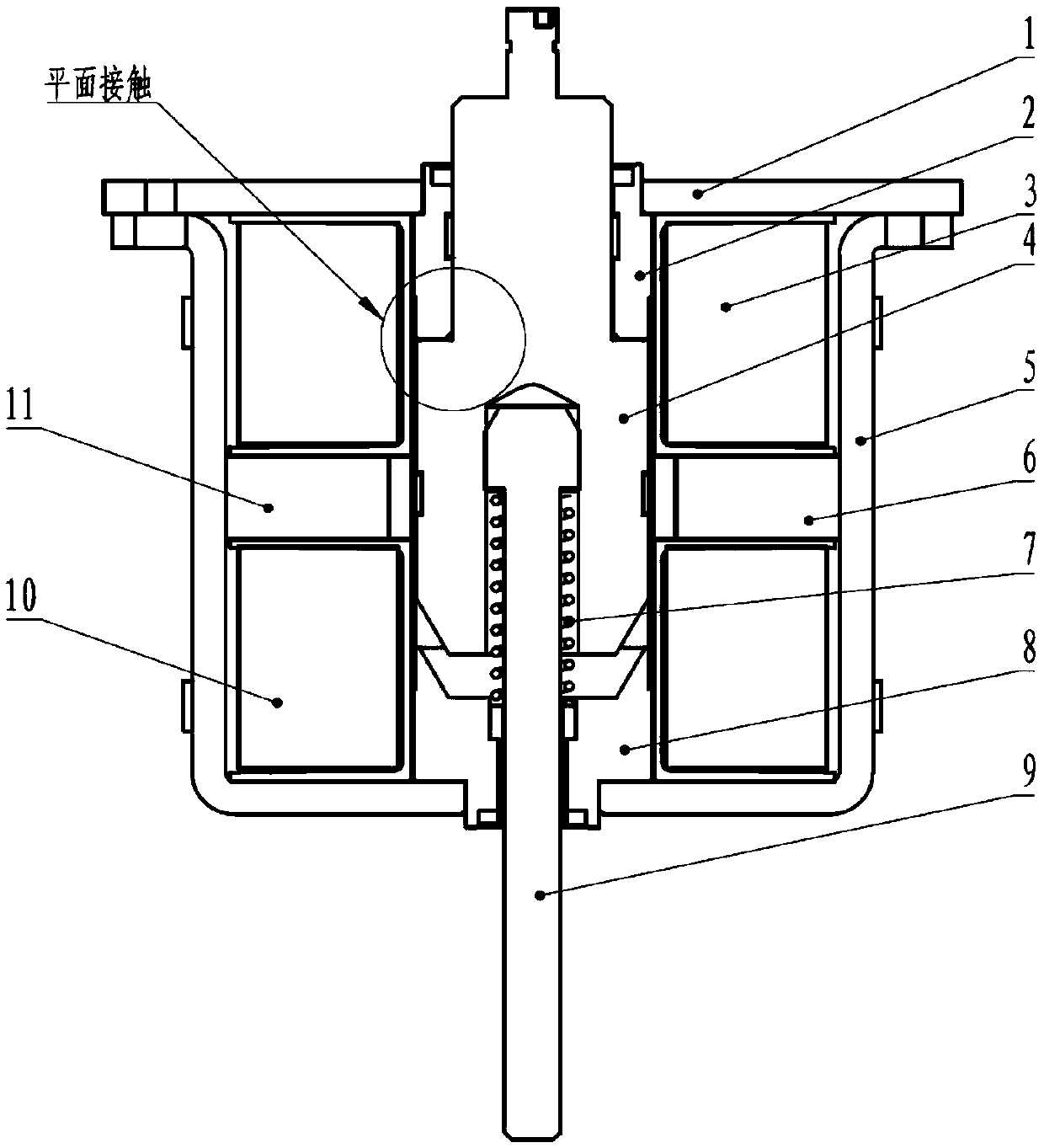

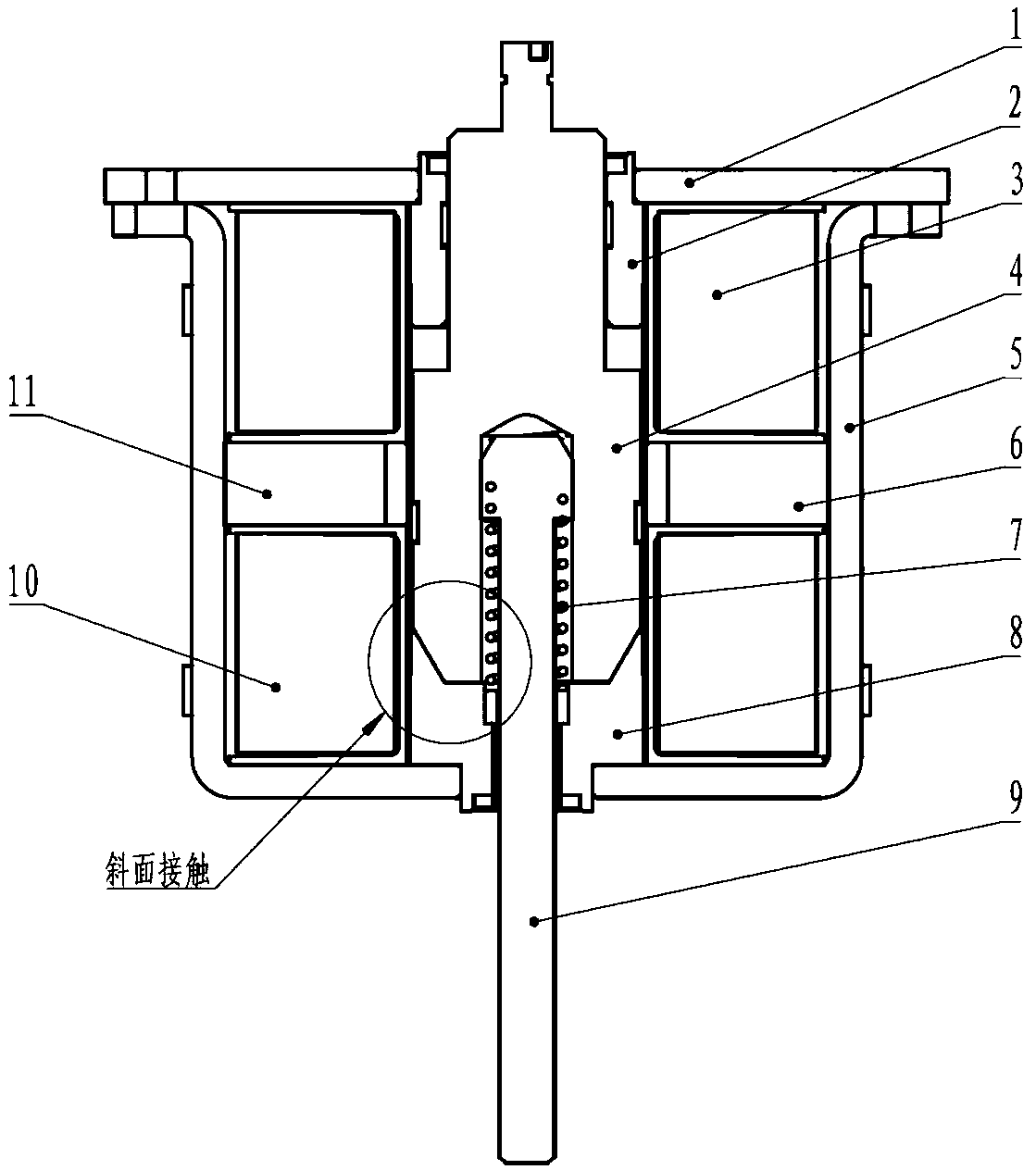

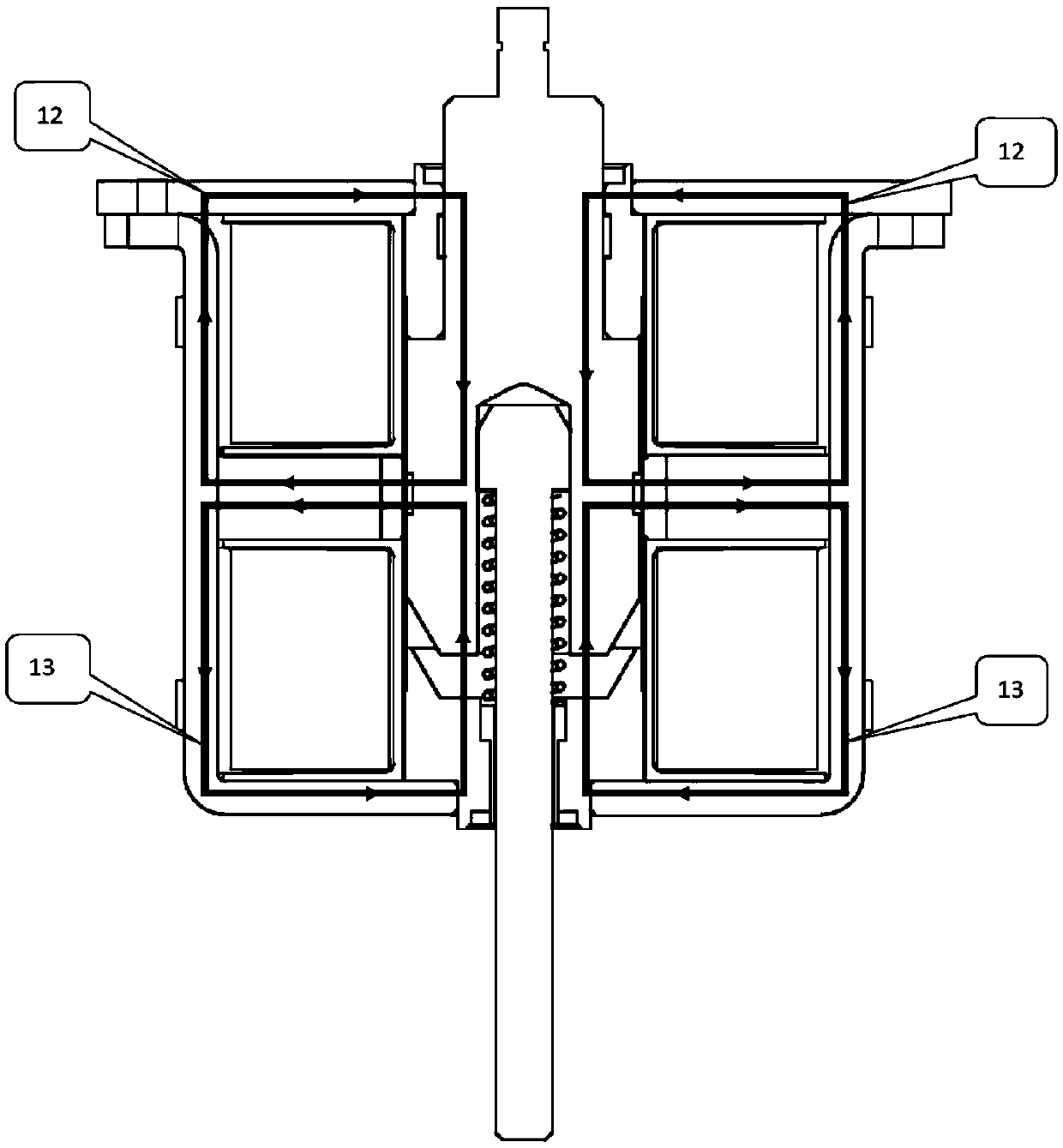

[0017] like Figure 1-2 As shown, the magnetic circuit structure of the middle magnetic steel with inclined surface contact provided by the present invention includes an upper iron core 2, a lower iron core 8, an armature 4, a transmission rod 9 and a magnetic part for providing a magnetic circuit, and the upper iron core 2 The plane contact with the armature 4, the slope contact between the lower iron core 8 and the armature 4, one end of the transmission rod 9 and the armature 4 are riveted together by rivets to form the armature part, and the main compression spring 7 is arranged between the two; The magnetic part is located on the outer periphery of the upper iron core 2 and the lower iron core 8 .

[0018] Here, the side of the armature 4 in contact with the lower iron core 8 is a bevel chamfer structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com