Anti-resonance photoelectric composite cable and application thereof

A technology of photoelectric composite cable and photoelectric unit, which is applied in the direction of communication cables, cables, circuits, etc., can solve the problems of unstable optical fiber excess length, poor tear resistance performance, and poor mechanical performance, so as to ensure the control of communication functions and improve Effects of anti-vibration performance and good cushioning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to better understand the purpose, structure and function of the present invention, an anti-resonance photoelectric composite cable provided by the present invention and its application will be further described in detail below in conjunction with the accompanying drawings.

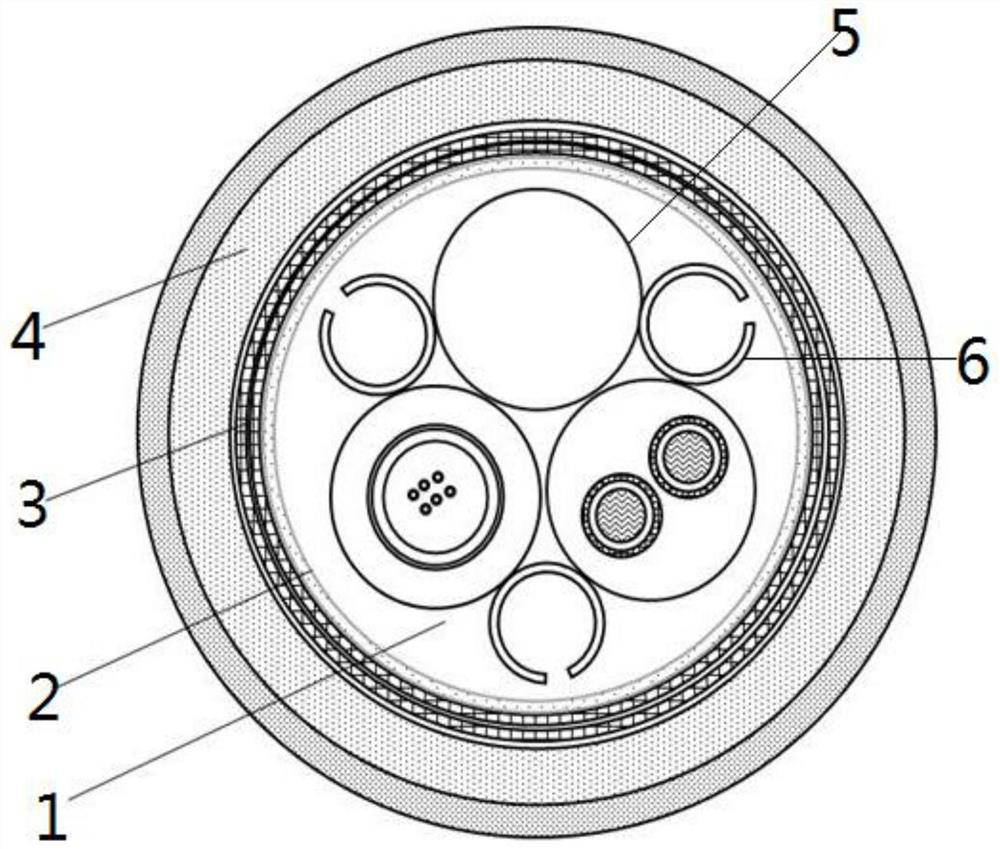

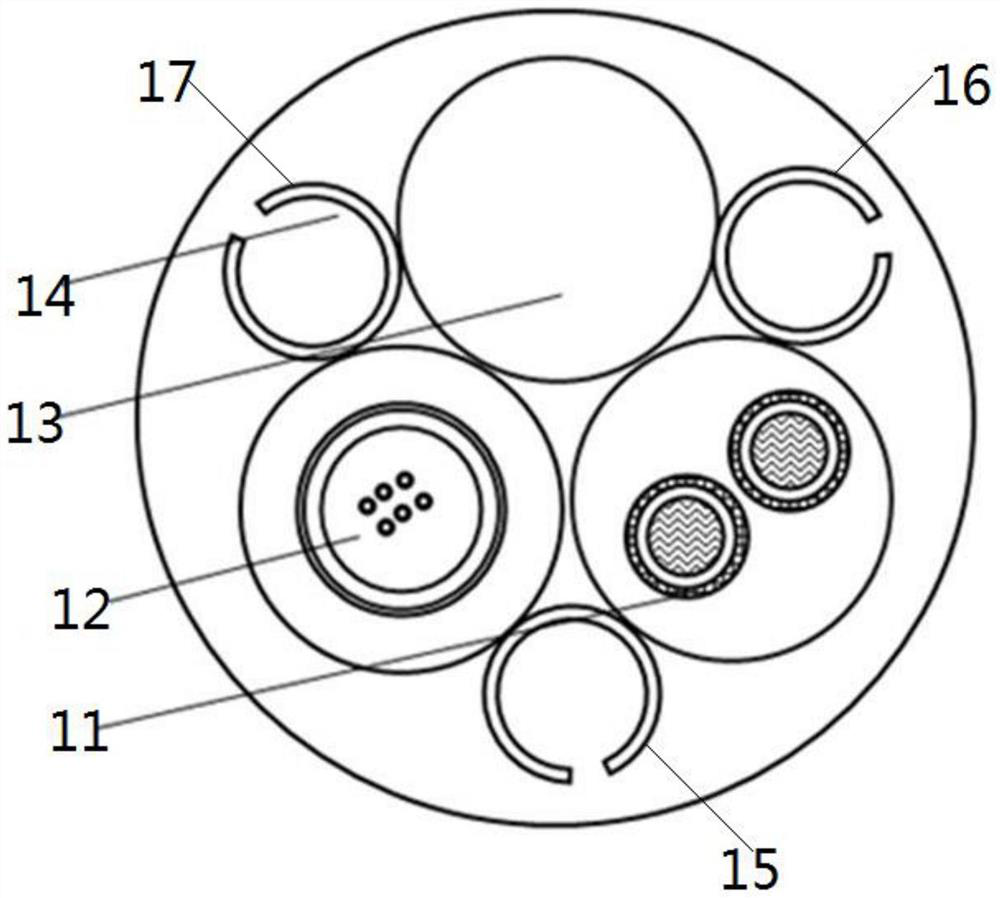

[0032] Such as figure 1 As shown, an anti-resonance photoelectric composite cable provided by the present invention includes: a special-shaped anti-resonance cable core 1, and the special-shaped anti-resonance cable core 1 is sequentially covered with a Kevlar fiber wrapping reinforcement layer from the inside to the outside 2. Double-layer front and back wrapping glass fiber reinforced tape layer 3 and high-density polyethylene and nylon double-layer co-extruded reinforced sheath layer 4; the special-shaped anti-resonance cable core 1 includes: EV electrical conductor unit 11, optical signal unit 12 and FRP reinforcing rod 13, the EV electrical conductor unit 11, the optical signal unit 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com