Assembly type freezer

A freezer, prefabricated technology, applied in infrastructure engineering, construction, soil protection and other directions, can solve the problems of single, unable to adjust the length of the freezing pipe, unable to stop freezing at any time, etc., to achieve the effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

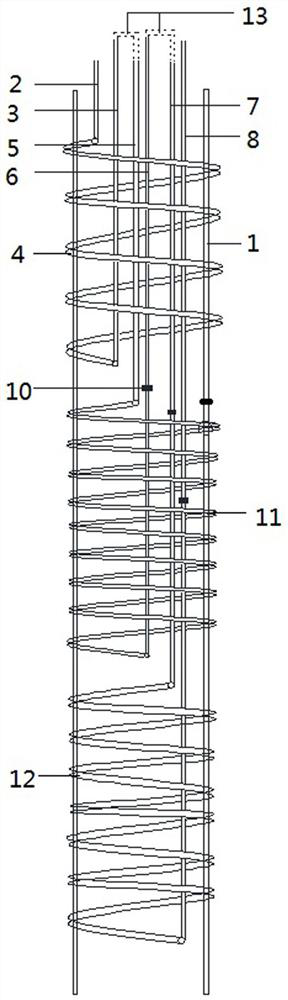

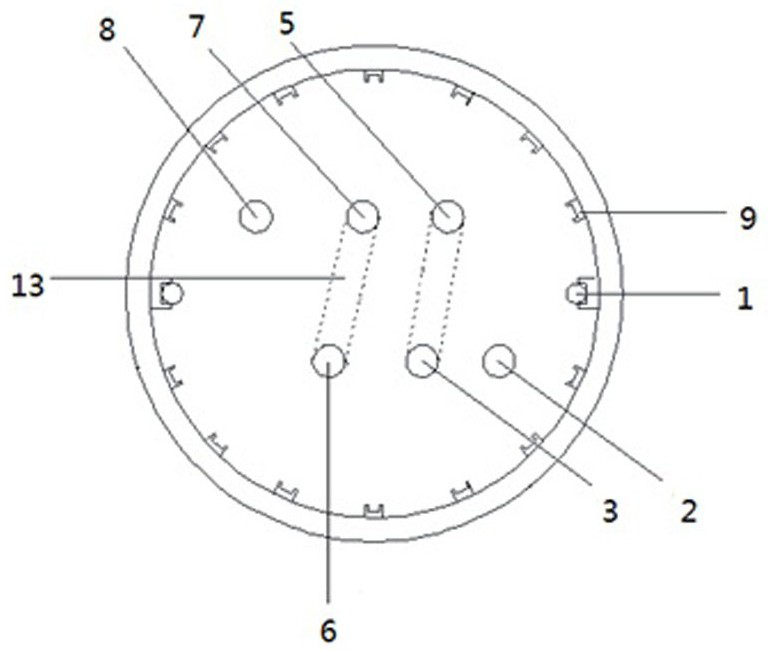

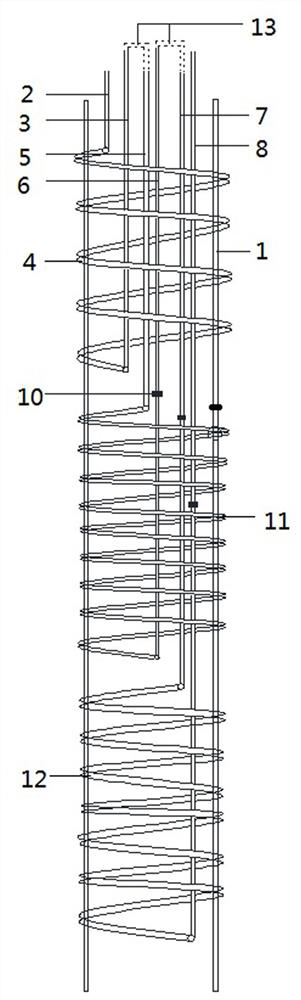

[0021] Embodiment: An assembled freezer, which can realize segmental freezing of soft soil at different depths by arranging freezing tubes in segments.

[0022] refer to figure 1 , figure 2 , including two parallel guide rails 1 vertically inserted in the soft soil, a freezing hole for placing freezing pipes is provided in the soft soil, and three sections of freezing pipe A, freezing pipe B, upper middle and lower sections are arranged on the guide rail 1 And the freezing pipe C, the freezing pipe A includes the first feed pipe 2 and the first air outlet pipe 3 parallel to the guide rails 1 and between the two guide rails 1, and the upper ends of the first feed pipe 2 and the first air outlet pipe 3 all extend On the ground, its lower end communicates with the first helical tube 4, and the first helical tube 4 is helically wound on the outside of the guide rail 1, and the freezing tube B includes a second feeding tube 5 parallel to the guide rail 1 and positioned between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com