Abrasive scratching and quick stop test method for cbn tool pre-repaired ferrous metal specimens

A technology of ferrous metals and testing methods, applied in the direction of measuring devices, instruments, and mechanical devices, etc., can solve problems that have not been reported, and achieve the effects of ensuring accuracy, improving quality, and ensuring relative motion accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

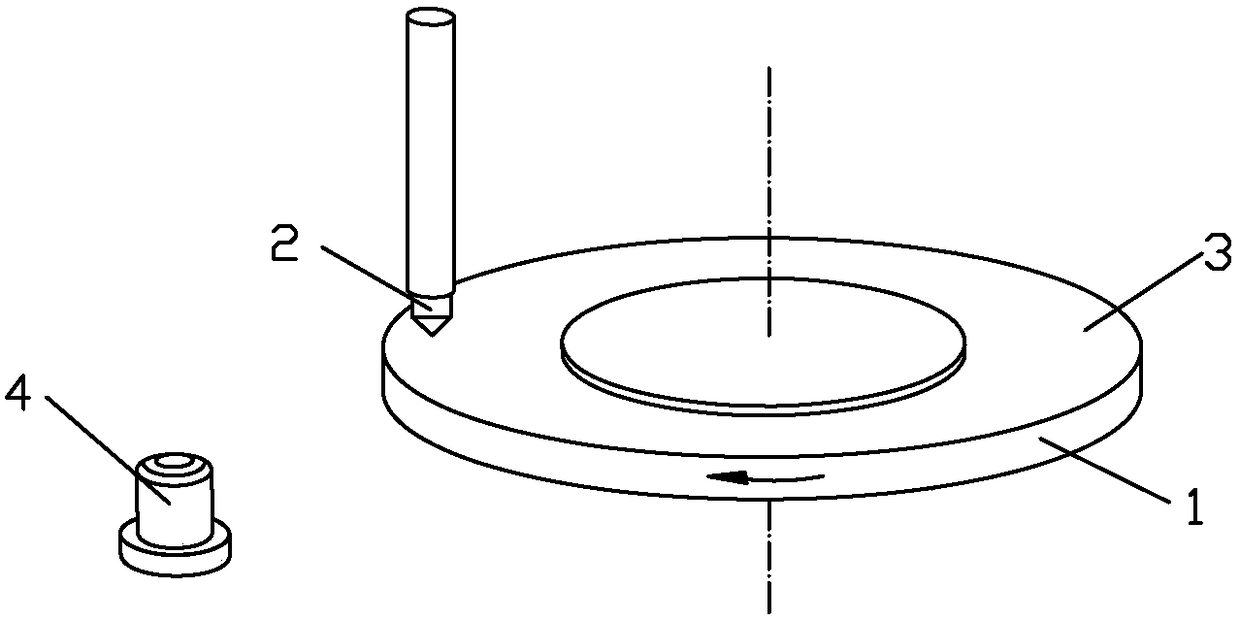

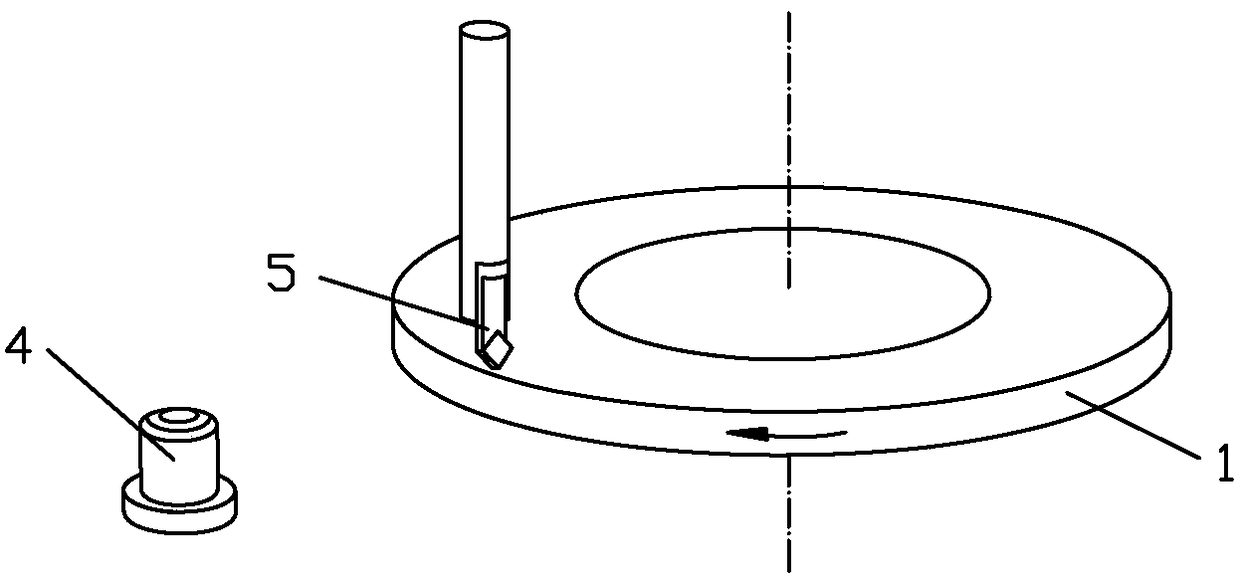

[0040] A CBN (cubic boron nitride) cutting tool pre-repaired ferrous metal test piece of single abrasive continuous scratch test method, the device used includes:

[0041] Machine tool, the disc-shaped ferrous metal test piece 1 is mounted on the electric spindle of the machine tool, and the test piece 1 can be rotated by the electric spindle;

[0042] A dynamic balancer, used for online dynamic balancing of the test piece 1;

[0043] The CBN single-point tool is a CBN single-point turning tool 5, which is used to repair the end surface of the test piece 1; the CBN single-point turning tool 5 is detachably attached to the bracket, and is movably attached to the machine tool through the bracket ;

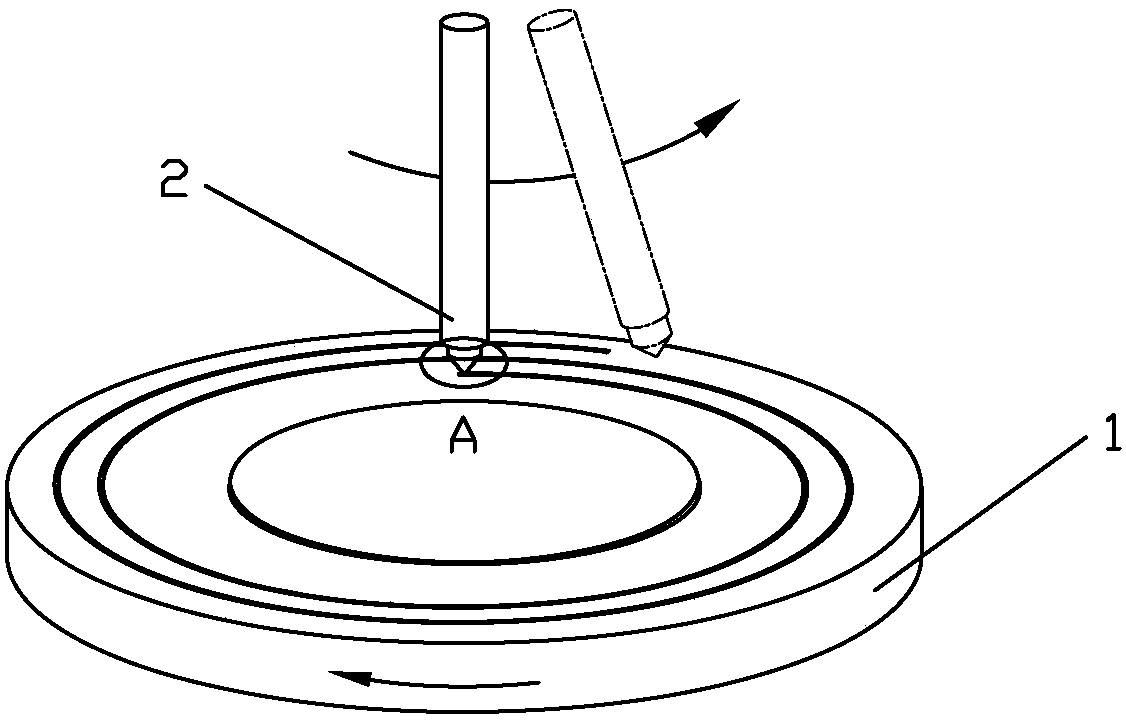

[0044]The tool head 2 is used for scratch testing; the top of the tool head 2 is fixed with a single grain of abrasive; the tool head 2 can be replaced with a CBN single-point tool and attached to the bracket in a detachable manner, and can be moved through the bracket The ground i...

Embodiment 2

[0062] The difference between this embodiment and Embodiment 1 is that a single spherical abrasive particle with a radius of 0.08 mm is brazed on the top of the tool head, and the rest are the same as Embodiment 1.

[0063] According to needs, the abrasive grains can be diamond, CBN, oxide ceramics or nitride ceramics; the shape of the abrasive grains can also be conical or polygonal; the abrasive grains are fixed on the tool by mechanical clamping, electroplating or brazing The tip of the head; the tool head can be in the form of an indenter or other consolidated abrasive grains.

[0064] According to the needs, adjust the parameters of the disk repair within the following range and perform one or more disk repairs to form a repair area on the surface of the test piece where the end face runout is better than IT1 grade and the average surface roughness Ra is better than 10nm:

[0065] 2-1) Rough machining of CBN single-point tool disk repair: vertical turning mode, cooling of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com