A High-Throughput Freezing Experimental Model of Spallation Damage Evolution and Its Realization Method

A damage evolution and experimental model technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of inability to obtain spall damage evolution process, low experimental efficiency, inconsistent control of loading conditions, etc., to improve efficiency and accuracy , the effect of improving the experimental efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The implementation mode of the present invention is illustrated by specific specific examples below, and those who are familiar with this technology can easily understand other advantages and effects of the present invention from the contents disclosed in this description. Obviously, the described embodiments are a part of the present invention. , but not all examples. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

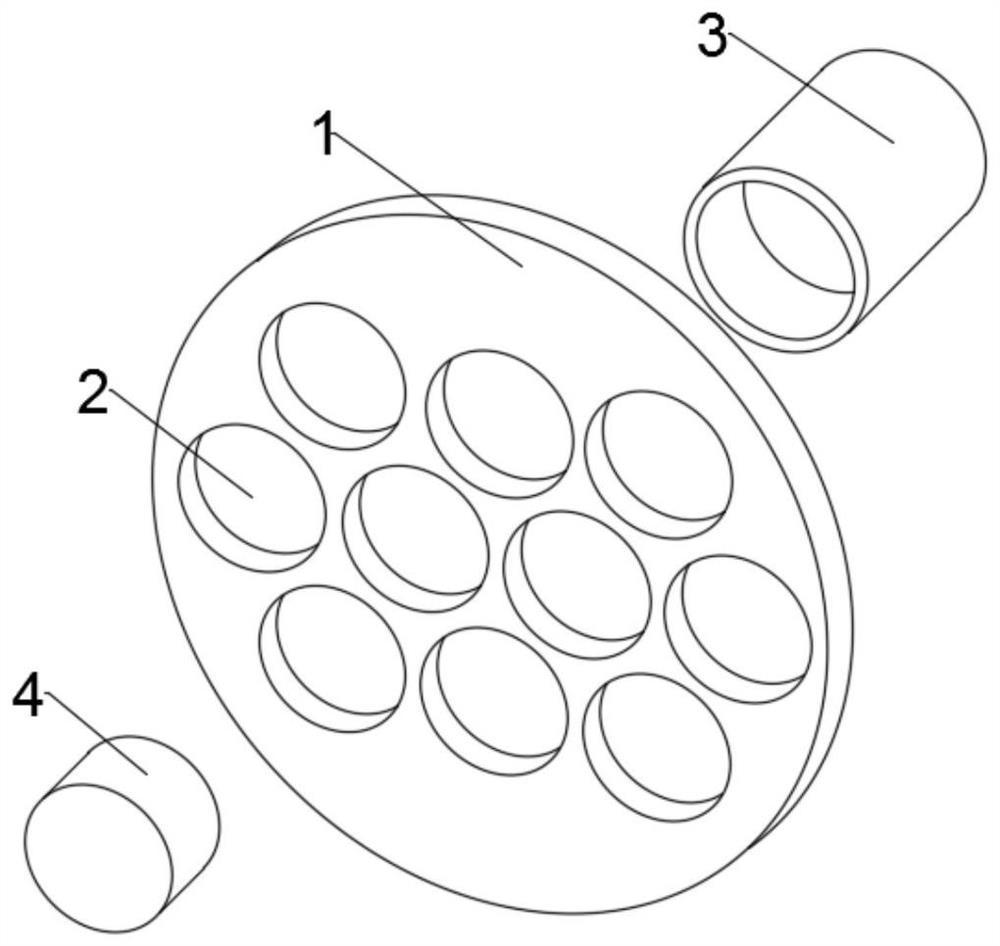

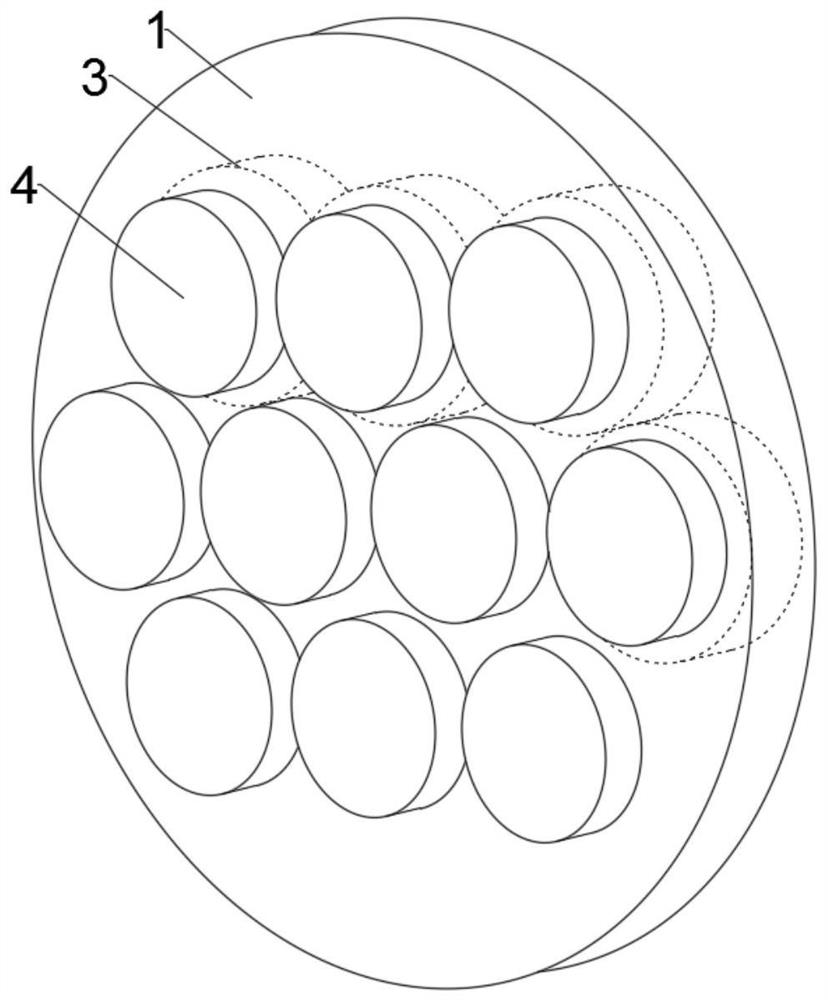

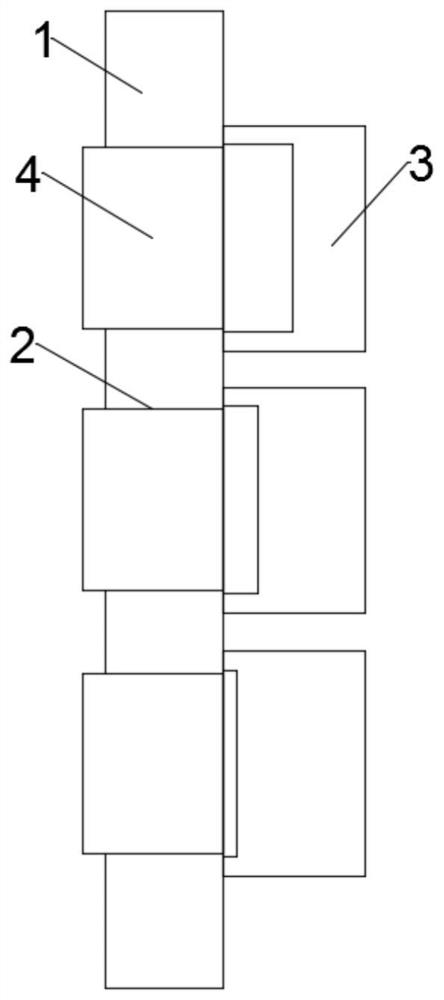

[0033] Such as Figure 1 to Figure 3 As shown, the present invention provides a high-throughput freezing experimental model of spallation damage evolution. The present invention changes the traditional flat-plate impact test method that only loads a single target plate, and uses multiple combined target plates as the experimental object. As long as the control The initial experimental conditions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com