Sewage channel wall element

A technology of channel walls and components, which is applied in the fields of application, tobacco, and cigarette manufacturing, and can solve problems such as increasing structural complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

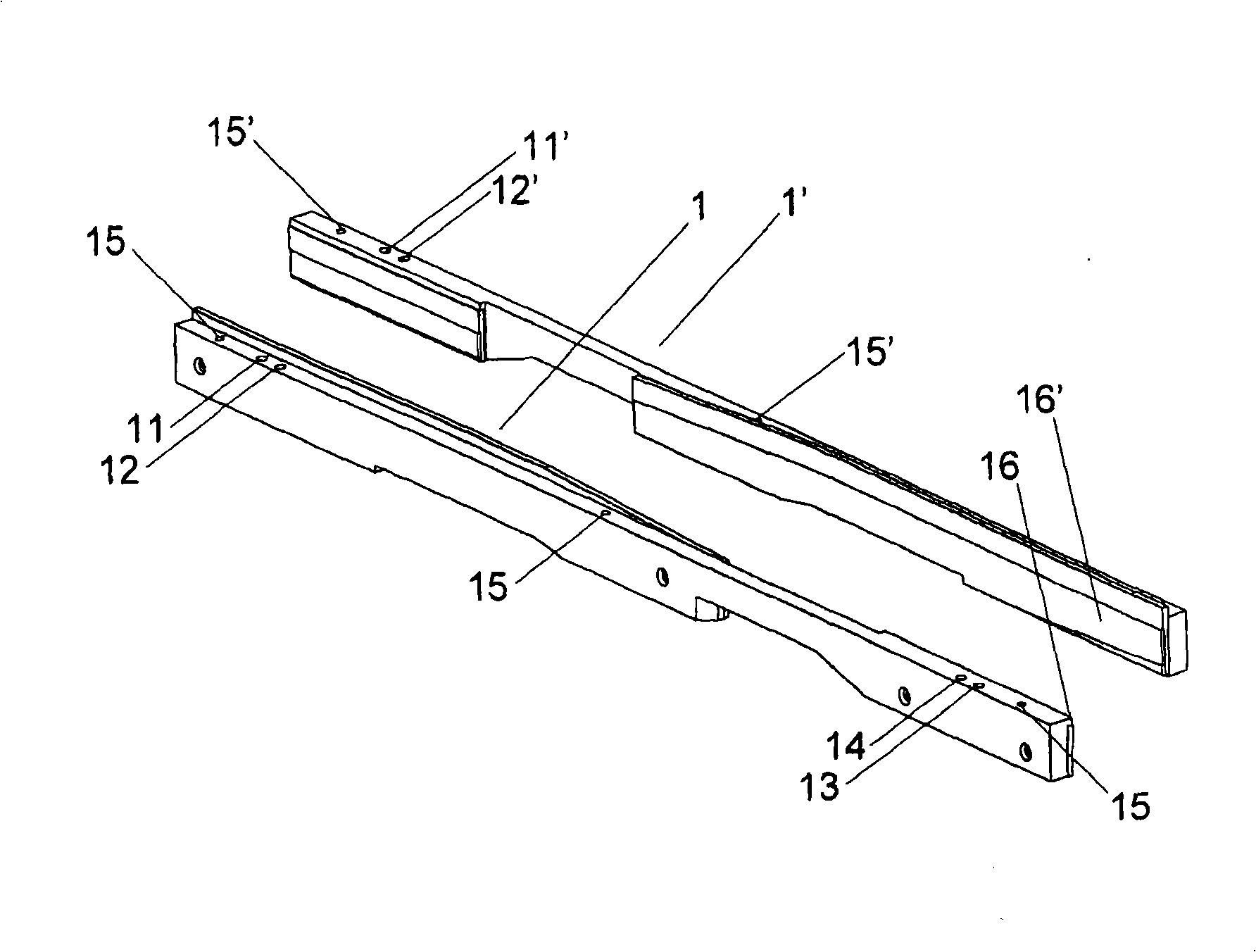

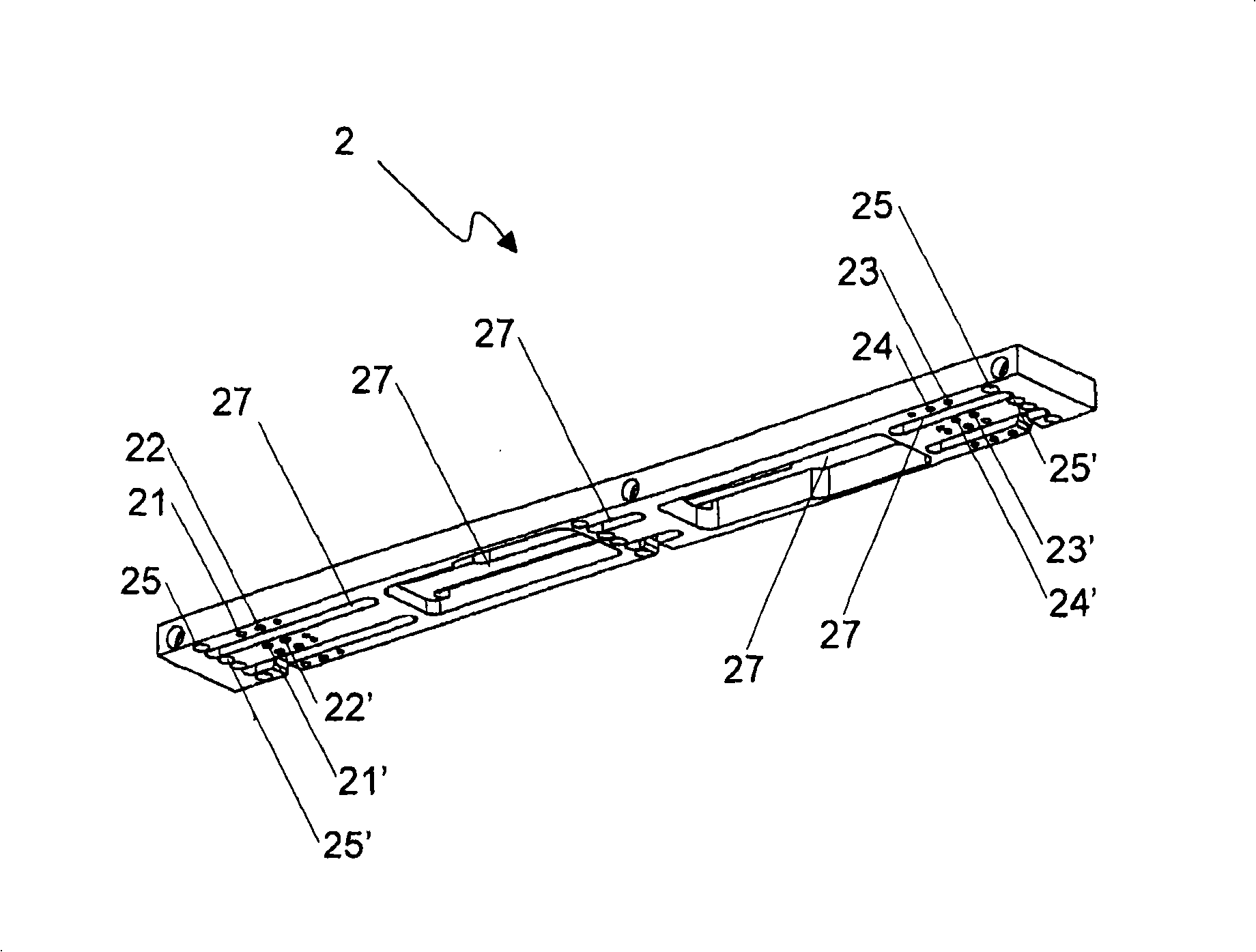

[0022] figure 1 Shown is a pair of tobacco passage wall elements 1, 1' according to the invention, which together form the side walls of the tobacco passage in the rod forming region of a cigarette rod-making machine. exist figure 1 The paired arrangement shown in substantially corresponds to the parallel arrangement within the tobacco duct system, in which a duct base element of complementary design is additionally included. exist figure 2 The channel base element 2 described is shown in . It should be pointed out here that the figure 1 The tobacco passage wall elements 1, 1' shown in are chosen for the sake of clarity with a greater distance between the tobacco passage wall elements 1, 1' than in an actual tobacco passage system.

[0023] exist figure 1 The tobacco channel wall elements 1, 1' shown in are configured as narrow strip-like parts, whose dimensions in the longitudinal direction are greater than in the transverse direction and are in most cases made of metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com