High-temperature tension test clamp of ultra-low-modulus composite material and test method of high-temperature tension test clamp

A composite material and tensile test technology, applied in the direction of analyzing materials, using stable tension/pressure testing material strength, measuring devices, etc., can solve problems such as clamping end damage, affecting the accuracy of test results, and sample damage , to achieve the effect of eliminating thermal stress, solving easy damage and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

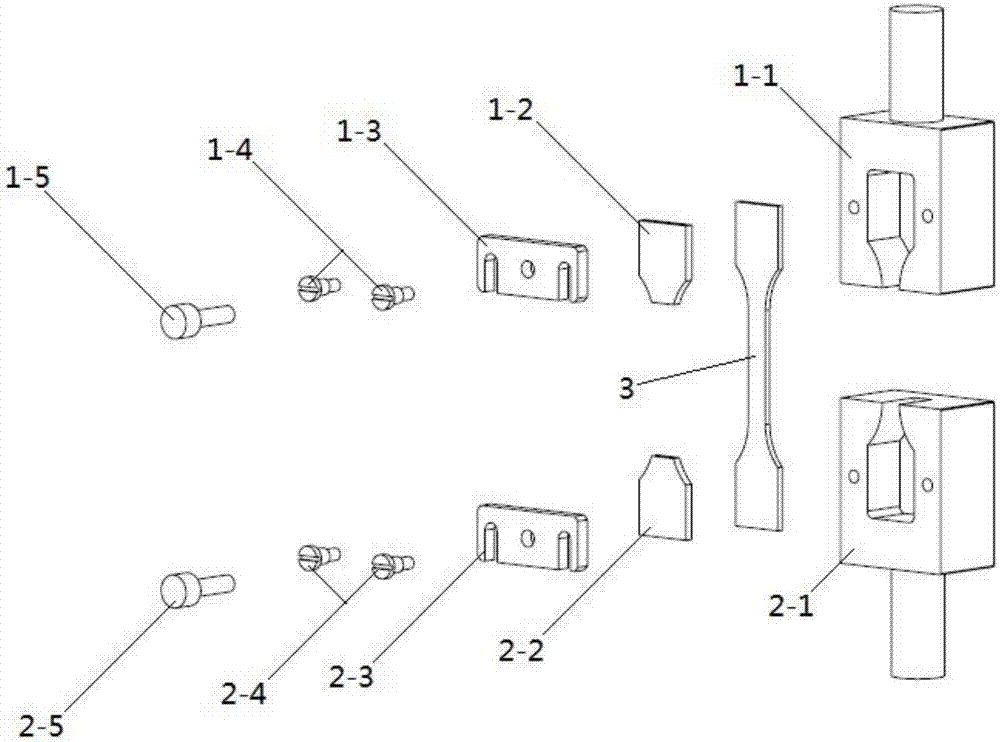

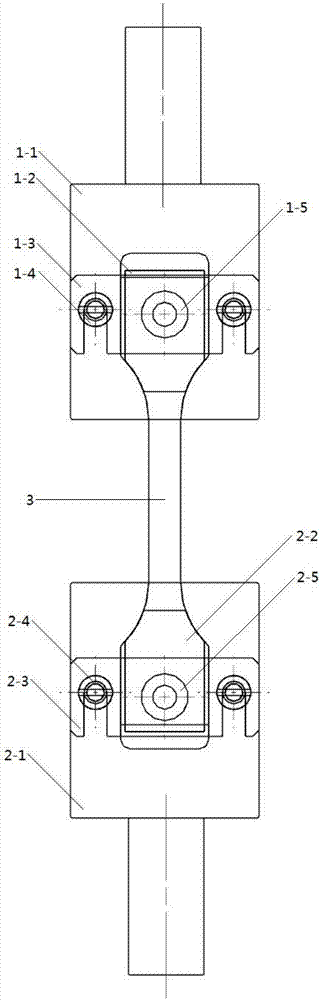

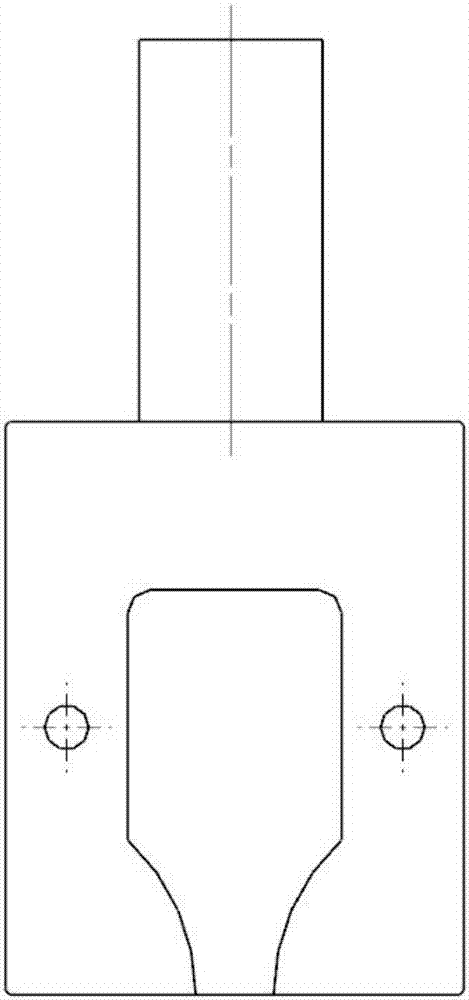

[0034] combine figure 1 and figure 2 As shown, the present invention provides a test fixture for high-temperature tensile of extremely low modulus composite materials, the fixture includes an upper tensile unit 1 and a lower tensile unit 2; The sample is positioned and fixed, the lower stretching unit 2 is connected with the sample through the arc end face, and the flat sample 3 is fixed through the spacer.

[0035] When carrying out the test, at first the flat sample 3 is placed on the arc end face of the first U-shaped fixture 1-1, so that the arc end face of the sample 3 coincides with the arc end face of the first U-shaped fixture 1-1; Then, put the first gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com