Experimental device for impact wear between heat exchange tubes

An experimental device and technology of heat exchange tubes, applied in the field of heat exchange tubes, can solve the problems of accelerating fatigue cracks of heat exchange tubes, economic losses, shortening the working time of equipment parts, etc., and achieve the effect of ingenious design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

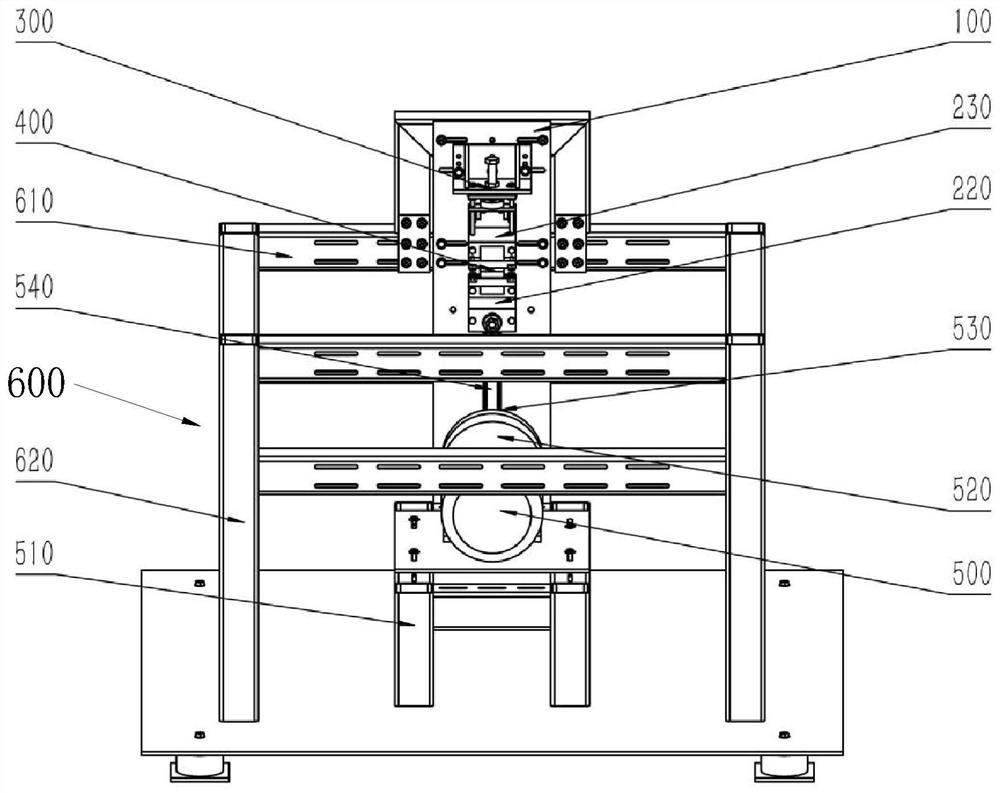

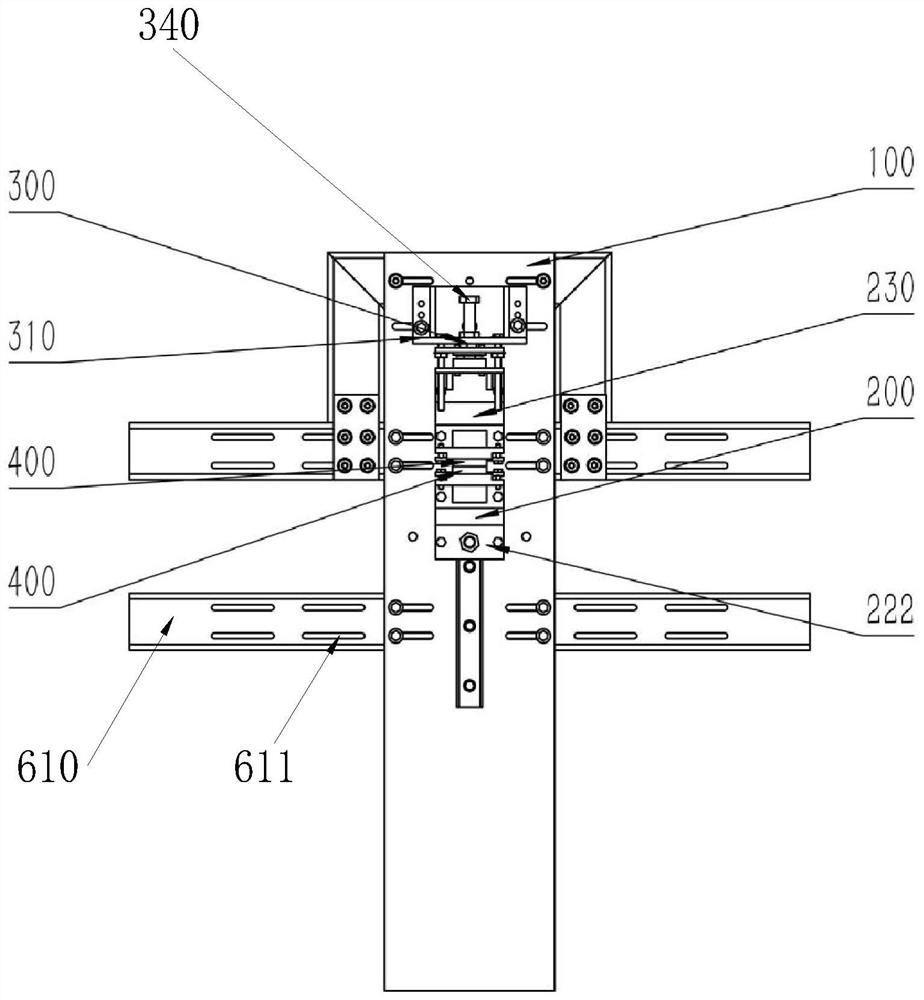

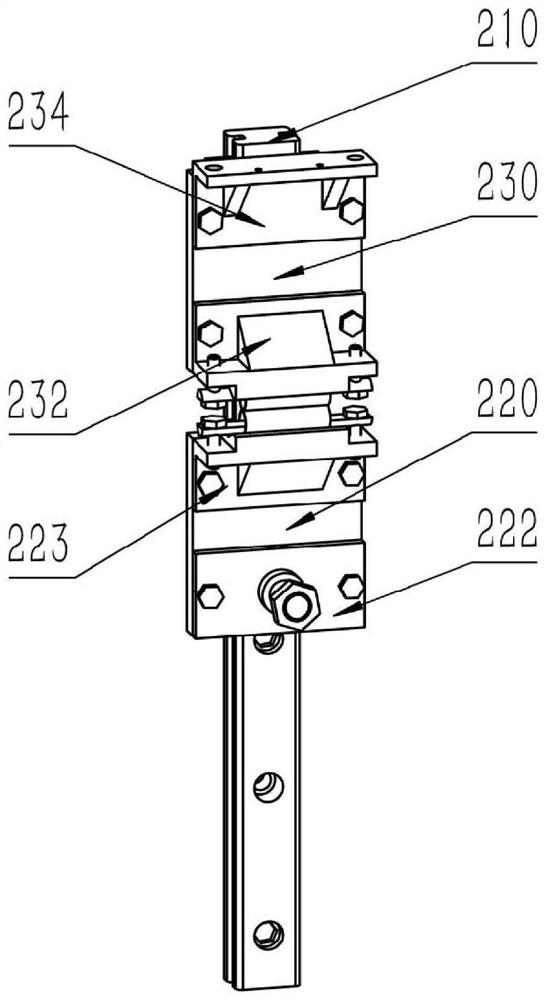

[0031] like Figure 1-6 As shown, an impact wear test device between heat exchange tubes provided in this embodiment includes a fixing mechanism, a supplementary device 300 and a power assembly 500; the fixing mechanism includes a fixing bottom plate 100, and the fixed bottom plate 100 is used for fixing clips The holding assembly 200 and the supplementary feeding device 300 are provided; wherein, the supplementary feeding device 300 is arranged on the upper end of the fixed bottom plate 100 ; the power component 500 is connected with the clamping component 200 .

[0032] The supplementary device 300 acts on the heat exchange tube 400 and is disposed on the upper side of the fixed bottom plate 100 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com