Arched truss ground counter-force pre-pressing device

A technology of arched trusses and booster devices, which is applied in the direction of erection/assembly of bridges, bridge forms, bridges, etc. It can solve the problems of difficulty in ensuring the safety of construction workers working at heights, the self-heavyness of the support beams, and the large input of materials, and achieve the desired solution. Insufficient compressive load, short construction period and high preloading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below with reference to the accompanying drawings.

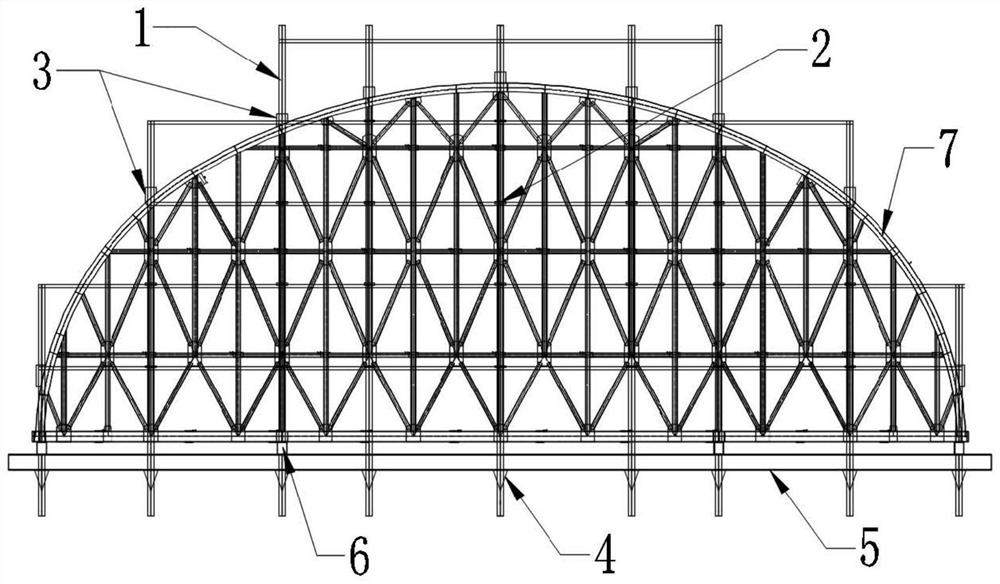

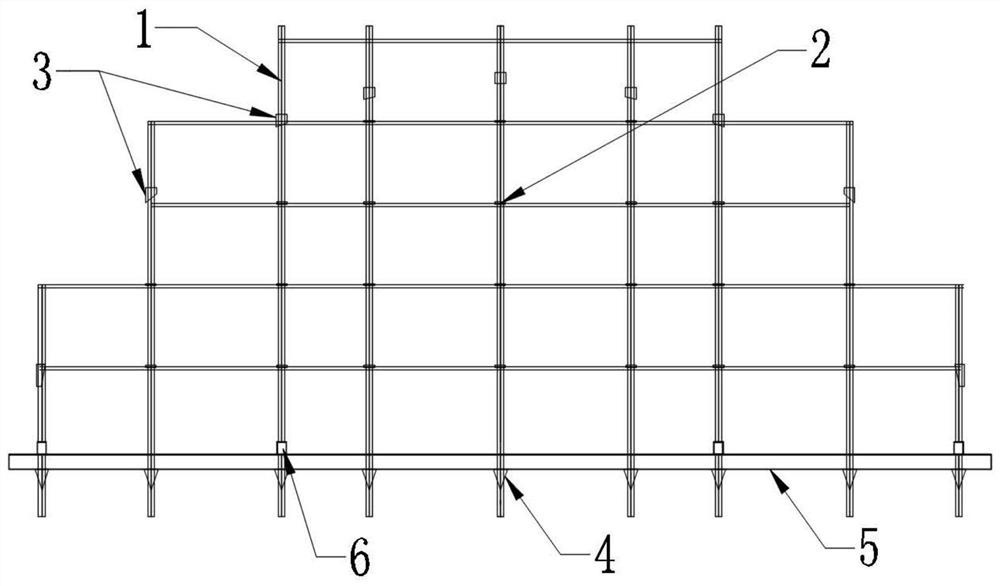

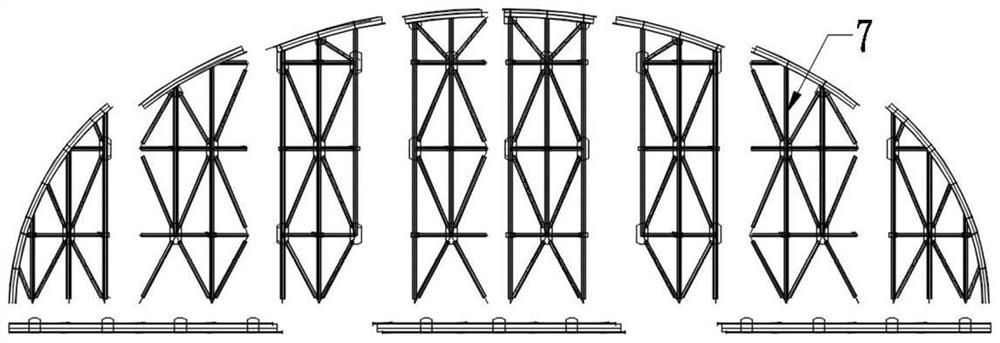

[0016] like figure 1 and figure 2 As shown, an arched truss ground reaction force precharge device includes a body, the body including a preload pedal 1 composed of a cross-rod and a vertical cross-connection, and a reaction-beam 5 fixed to the bottom of the vertical bar 5 The preload pedestal 1 is placed on the ground, and the preload pedal 1 is provided with an arched truss piece 7, and the preload pedestal 1 is fixed to the vertical rod and the arch circus of the truss sheet 4 fixed to the finite position 3, The restricted pier 3 is fixed to the vertical rod; the bottom end of the reactionary beam 5 supports the anti-mechanical pug 4 fixed on the vertical rod, the top end of the reaction beam 5 and the truss bottom beam of the truss piece 7 There is a power supply device 6 between it is provided between.

[0017] Wherein, the vertical intersection of the crossbar and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com