Low speed flow adjustable shock absorber piston

A shock absorber and piston technology, applied in shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve problems such as the need to improve the shock absorption experience, the poor effect of shock absorbers, and the complex structure, and achieve easy Manufacture and assembly, compact structure, effect of few piston parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

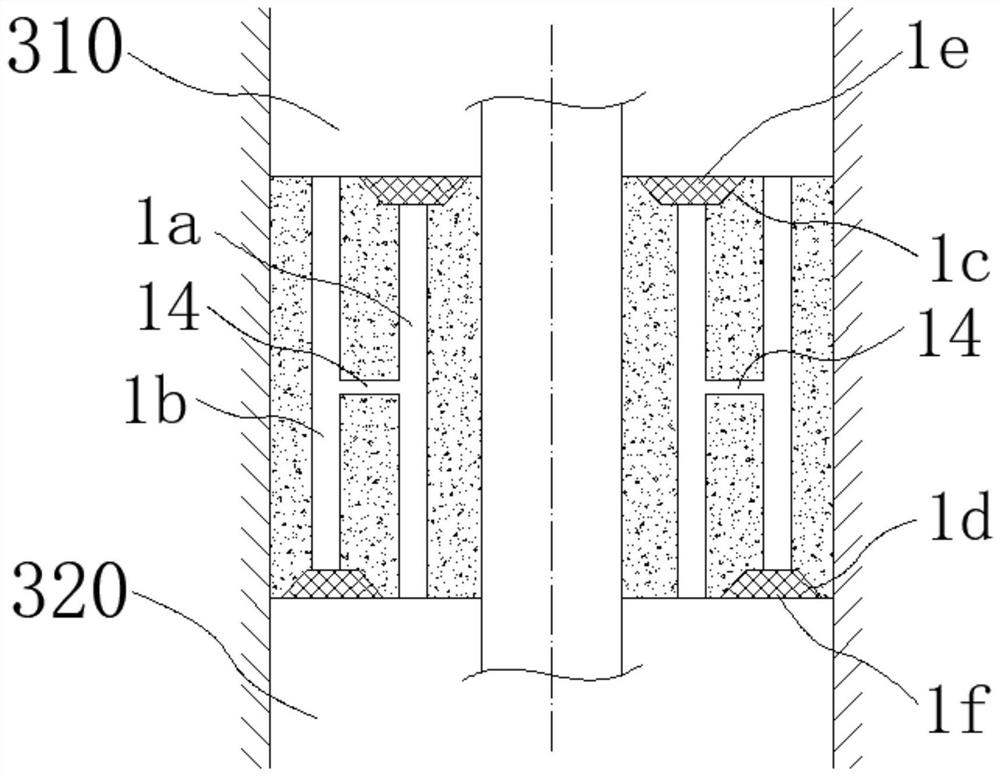

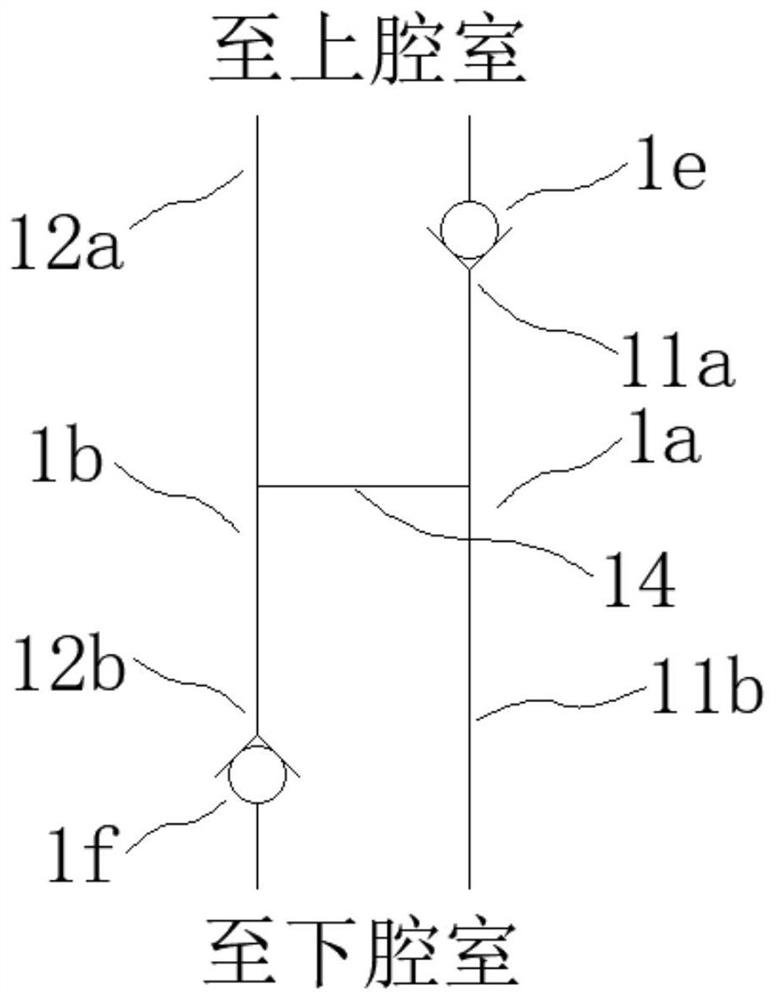

[0068] like figure 1 , 2 As shown, a low-speed flow-adjustable shock absorber piston (referred to as a piston) includes a piston body for fitting in a piston cavity. After fitting, an upper chamber 310 is formed above the piston body, and a lower chamber 320 is formed below. .

[0069] The piston also includes a number of first channel groups 1a and a number of second channel groups 1b penetrating the piston body respectively to communicate with the upper and lower chambers; the piston body also includes a first valve position 1c arranged on its upper end surface and a first valve position 1c arranged on its lower end surface. The second valve position 1d, the first channel group 1a is communicated with the first valve position 1c to open or close the first channel group 1a and the upper chamber 310 through the first valve member 1e disposed at the first valve position 1c The first valve member 1e controls whether the first channel group 1a is connected up and down; the seco...

Embodiment 2

[0076] like Figure 3-10 As shown, a low-speed flow-adjustable shock absorber piston (referred to as a piston) includes a piston body for fitting in a piston cavity. After fitting, an upper chamber 310 is formed above the piston body, and a lower chamber 320 is formed below. .

[0077] The piston further includes several first channel groups and several second channel groups respectively penetrating the piston body to communicate with the upper and lower chambers.

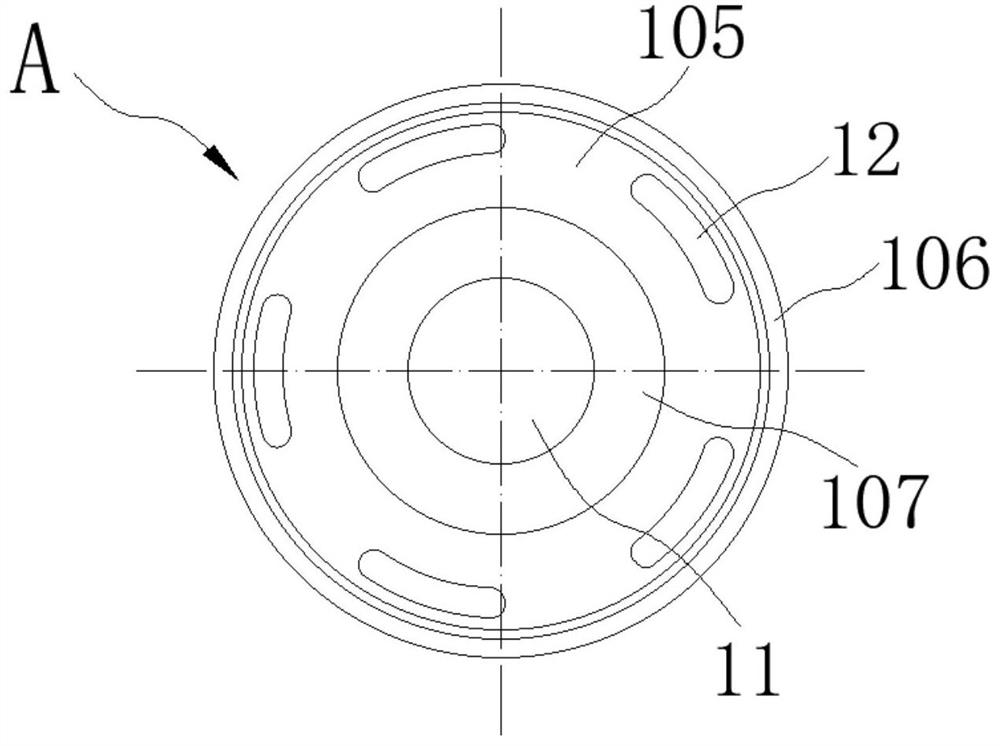

[0078] The piston is composed of a first piston A and a second piston B that cooperate with each other. The first piston A and the second piston B are respectively in the shape of a cylinder or a cylinder-like shape. The lower end of the first piston A and the upper end of the second piston B cooperate to form the piston.

[0079] The first piston A has a first piston upper end surface 101, a first piston side wall 102 and a first piston lower end surface 103, the first piston A is also provided with a first cent...

Embodiment 3

[0109] like Figure 11 As shown, a low-speed flow-adjustable shock absorber piston (referred to as a piston) includes a piston body for fitting in a piston cavity. After fitting, an upper chamber 310 is formed above the piston body, and a lower chamber 320 is formed below. . The main structure is the same as that of the second embodiment, and the only difference is that the setting position of the adjustment channel 14 of the present embodiment is different from that of the second embodiment.

[0110] In this embodiment, the bottom surface of the first piston A is flat, and the upper end surface 201 of the second piston is provided with an adjustment channel 14 . Moreover, in this embodiment, the adjustment channel 14 communicates with all the first and second channels.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com