Automatic stator scattered sheet splicing and superposing machine

A stator and frame technology, which is applied in the field of automatic stator patchwork laminating machines, can solve problems that do not involve the integrated operation of stator patchwork stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

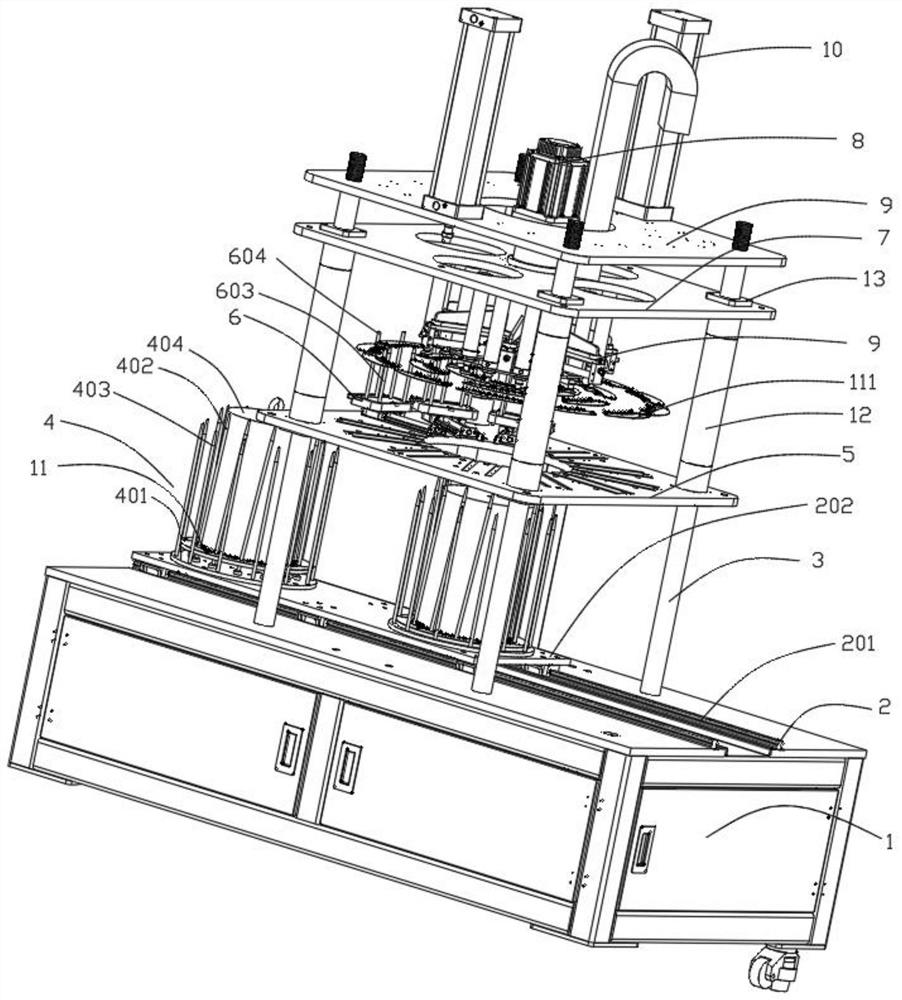

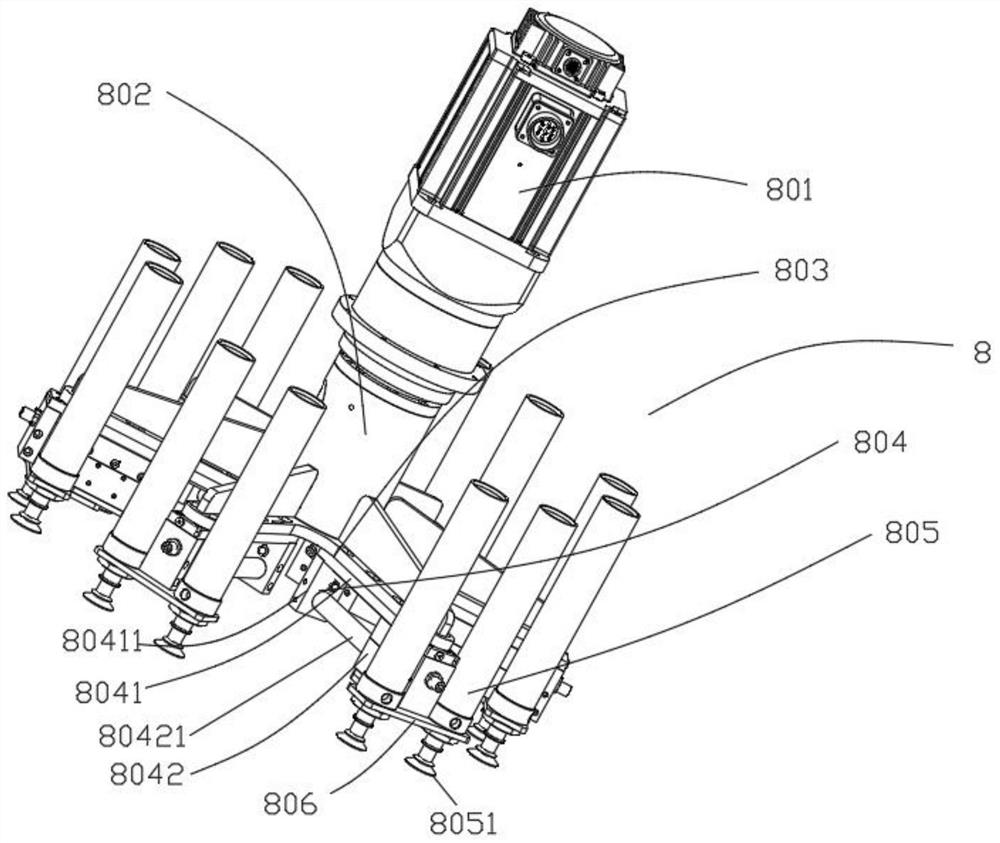

[0025] see Figure 1~3 , in the embodiment of the present invention, the automatic stator loose piece splicing machine includes a frame 1, a finished material level switching device 2 and a guide post 3 arranged on the table of the frame 1, and a finished material level switching device 2 arranged on the finished material Positioning device 4, loose piece placing plate 5 and motor fixing plate 7 socketed on guide post 3. The finished material level switching device 2 is connected to a control system (not shown in the figure).

[0026] In this embodiment, the finished material level switching device 2 includes a drive device (not shown in the figure) connected to the control system, two first guide rails 201 connected to the drive device, and a mobile platform fixed on the two first guide rails 201 202.

[0027] The finished material level device 4 includes a base plate 401 fixed on the mobile platform 202, a plurality of first guide columns 402 arranged on the base plate 401...

Embodiment 2

[0037] Different from Embodiment 1, a sleeve 12 is provided between the loose-piece placing plate 5 and the motor fixing plate 7, and the lower surface of the loose-piece placing plate 5 and the upper surface of the motor fixing plate 7 are fixed blocks with holes. 13, so as to realize the integral movement of the loose sheet placing plate 5 and the motor fixing plate 7.

[0038] The automatic stator splicing machine also includes a top plate 9, two drive cylinders (or oil cylinders) 10 are placed on any set of parallel sides on the top plate 9, and the drive ejector rod clamps the upper surface of the motor fixing plate 7, thereby driving the motor to fix The plate 7 and the sheet placing plate 4 move up and down together.

Embodiment 3

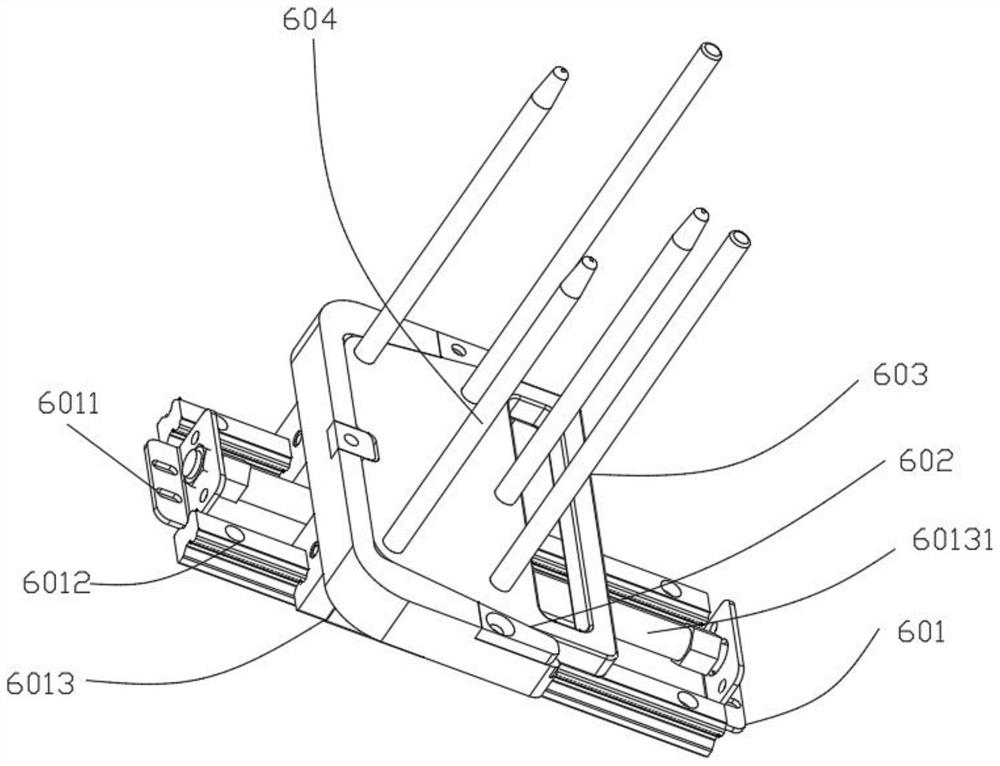

[0040] The difference from Embodiments 1 and 2 is that the number of the scattered storage devices 6 is doubled, and the scattered storage devices 6 are divided into two groups. When one group is working, the other group is on standby, and the two groups are staggered. A group of working loose sheet storage devices 6 is moved to the side close to the gap by the radial movement mechanism 601, and the spare group is moved to the side away from the gap by the radial movement mechanism 601, and the stator loose piece block 111 is ready, Uninterrupted work is achieved through two groups of alternate operations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com