Automatic airduct forming device

An automatic molding and blower technology, which is applied in the field of fan equipment, can solve the problems affecting the quality of the cylinder flanging, affecting the overall quality of the fan, and the decrease in roundness accuracy, so as to improve production quality, high degree of automation, and guarantee Effect of Period Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

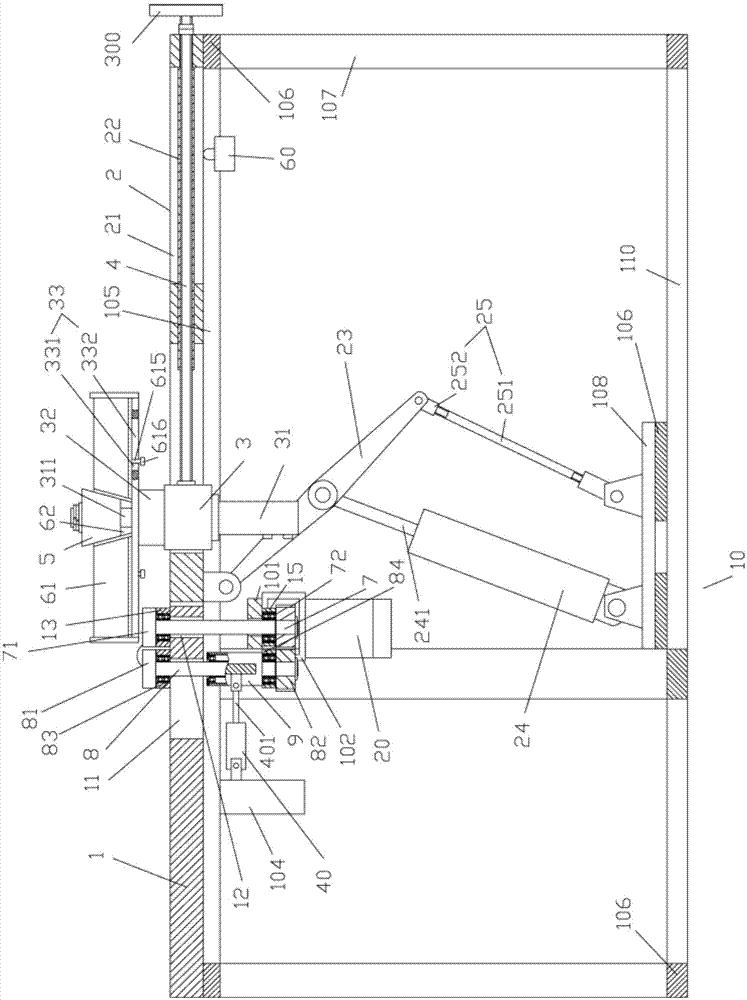

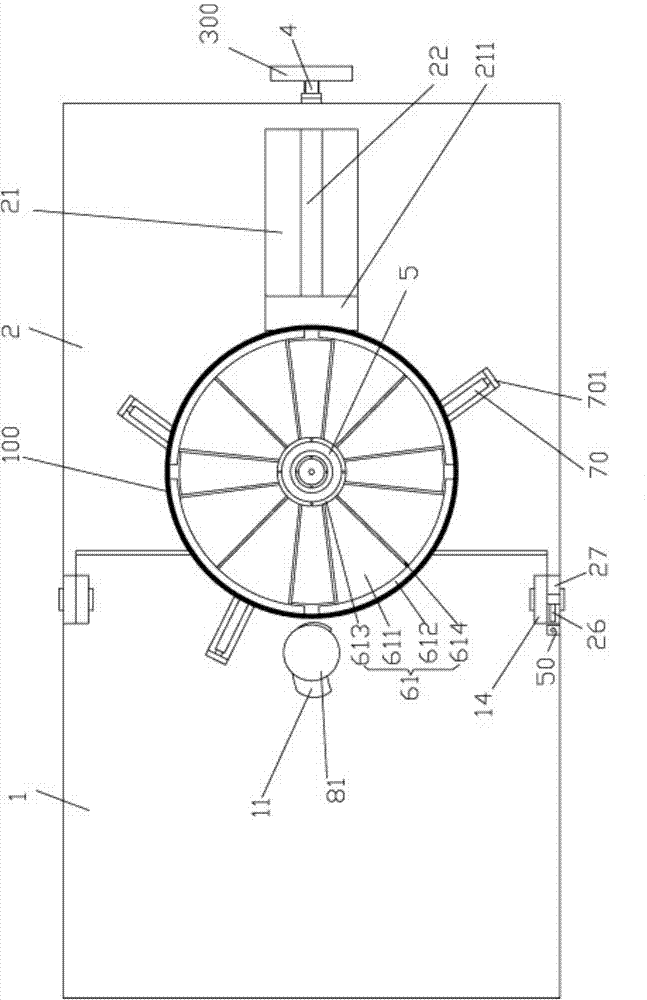

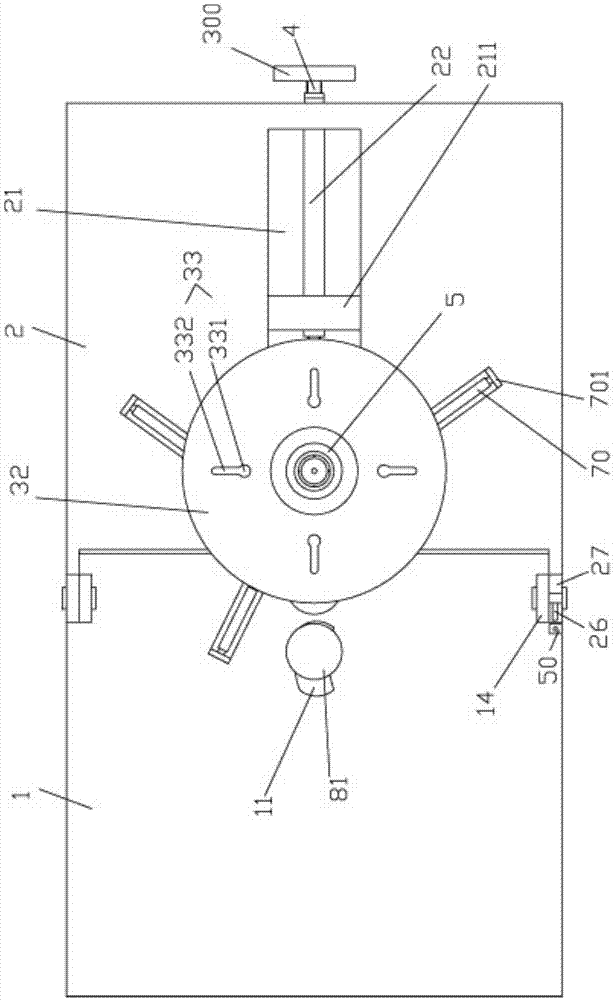

[0043] Example: see Figures 1 to 14As shown, a blower automatic forming device includes a frame 10, a support plate 1 is fixed on the top of the frame 10, and a turning plate 2 is hinged on one side of the support plate 1, and the turning plate 2 is pressed against the side of the frame 10. top;

[0044] An elongated through groove 21 is formed on the turnover plate 2, and the sliding block 3 is inserted in the elongated through groove 21. The middle part of the elongated through groove 21 is provided with an internally threaded sleeve 22, and one end of the internally threaded sleeve 22 is fixed on the long The right side wall and the other end of the elongated through groove 21 face the sliding block 3, and a through hole is formed between the right side wall of the elongated through groove 21 and the right side wall of the turnover plate 2, and the screw mandrel 4 passes through the through hole and is screwed. Connected in the internally threaded sleeve 22, the top end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com