Floating ball type drain valve rod and double-valve-element assembly

A steam trap and double-spool technology, which is applied to steam traps, machine tools designed for grinding the rotating surface of workpieces, grinding machines, etc., can solve the problems of coaxiality that cannot meet the requirements and reduce the air tightness of steam traps, etc. Achieve high coaxiality and ensure the effect of coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

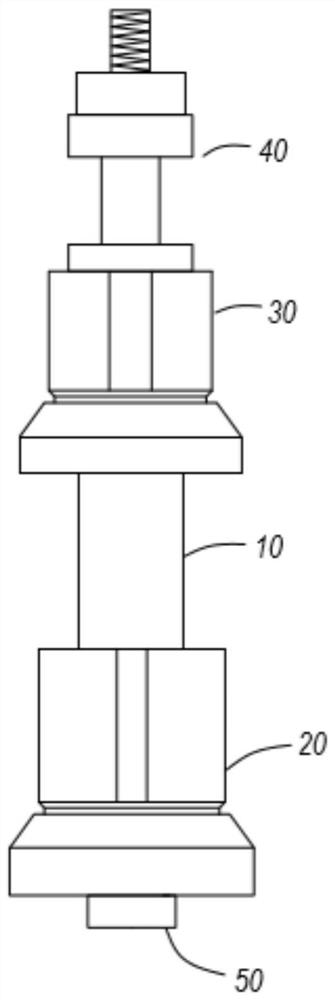

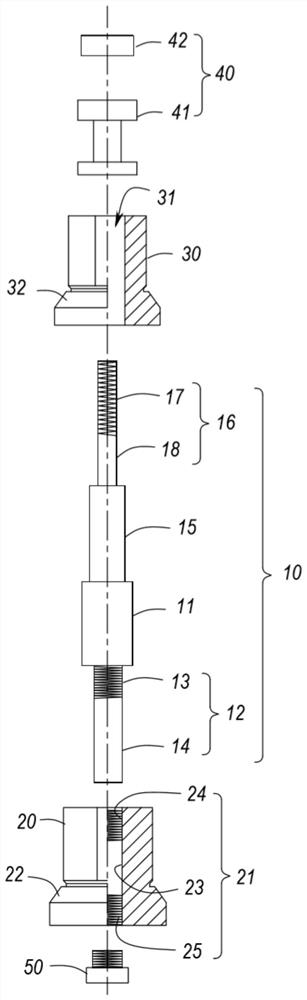

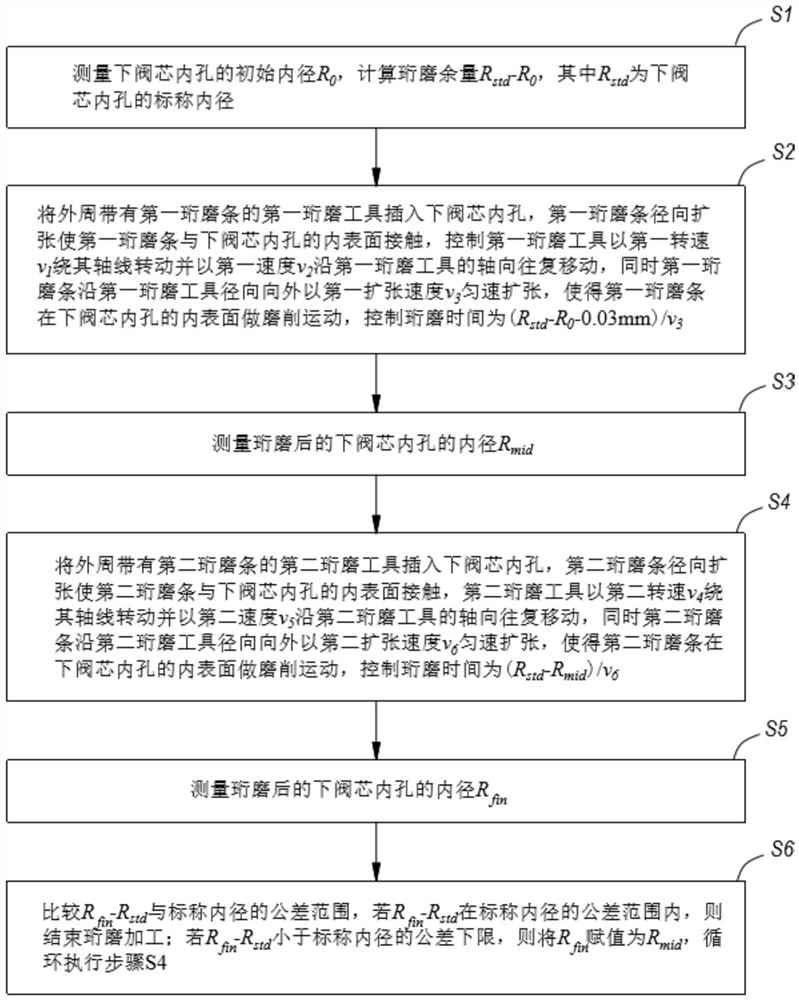

[0044] Please refer to figure 1 with figure 2 , Float trap valve stem and double spool assembly, including valve stem 10, lower spool 20, upper spool 30, fastening component 40 and screw 50. The lower valve core 20 is sleeved on the valve stem 10 , one end thereof is threadedly connected with the valve stem 10 , and the other end is provided with a screw 50 , and the screw 50 presses against the end of the valve stem 10 . The upper valve core 30 is also sleeved on the valve stem 10 and locked by a fastening component 40 .

[0045] Please refer to figure 2 The valve stem 10 includes an intermediate section 11, an upper valve core installation part 15 connected to the upper end of the intermediate section 11 with a diameter smaller than that of the intermediate section 11, a lower valve core installation part 12 connected to the lower end of the intermedia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com