Preparation method of high-compactness SiCf/SiC cladding composite pipe

A composite pipe and densification technology, which is applied in the field of preparation of silicon carbide ceramic matrix composite materials, can solve the problems of SiC pipe fittings such as difficulty in forming, and achieve the effects of simplifying hot pressing and sintering steps, ensuring circularity, and ensuring structural shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

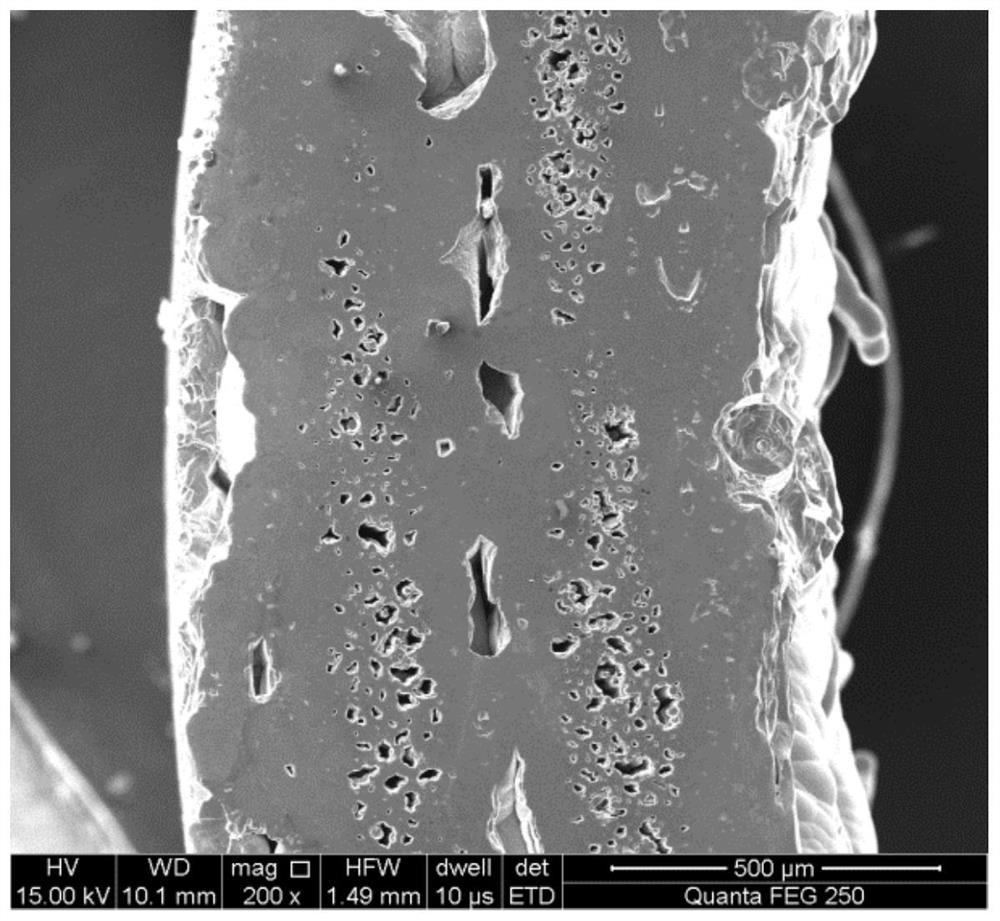

Image

Examples

Embodiment 1

[0041] A highly densified SiC f The preparation method of / SiC cladding composite pipe comprises the following steps:

[0042] S1: Preparation of low-density SiC f / SiC preform: braiding SiC fibers into tubes in 2D, with C 3 h 6 as the source gas, argon as the diluent gas to deposit the PyC interface layer, the deposition temperature is 1000°C, and the thickness is 200nm; MTS-H 2 -Ar is the reaction source gas, CVI deposition (SiC matrix deposition) is carried out at 1100 ° C and 200 Pa for 16 hours, and the obtained low-density SiC f / SiC preform with a density of 2.02g / cm 3 ;

[0043] S2: Preparation of SiC f / SiC green body: Disperse 10% of sintering aid, 5% of silicon carbide precursor, 40% of binder, 10% of plasticizer, and 35% of nano-SiC powder in organic dispersant, and mix them uniformly by ball milling. The ratio of ball to material is 10:1, and the time is 12h to make NITE-SiC slurry, and the NITE-SiC slurry is diffused into low-density SiC by impregnation f...

Embodiment 2

[0047] A highly densified SiC f The preparation method of / SiC cladding composite pipe comprises the following steps:

[0048] S1: Preparation of low-density SiC f / SiC prefabricated body: SiC fibers are braided into tubes in shallow intersection (2.5D), with C 3 h 6 as the source gas, argon as the diluent gas to deposit the PyC interface layer, the deposition temperature is 1050°C, and the thickness is 400nm; MTS-H 2 -Ar is the reaction source gas, CVI deposition is carried out at 1050°C and 200Pa for 30h, and the obtained low-density SiC f / SiC preform density is 2.11g / cm 3 ;

[0049] S2: Preparation of SiC f / SiC green body: sintering aid 10%, SiO 2 2% micropowder, 3% silicon carbide precursor, 10% binder, 5% plasticizer, and 70% nano-SiC micropowder are dispersed in an organic dispersant, mixed evenly by ball milling, and the ball-to-material ratio is 4:1. The time is 24h to make NITE-SiC slurry, and the NITE-SiC slurry is diffused into low-density SiC by impregnati...

Embodiment 3

[0053] A highly densified SiC f The preparation method of / SiC cladding composite pipe comprises the following steps:

[0054] S1: Low-density SiC f / SiC prefabricated body: SiC fibers are braided into tubes in a winding manner, and the C 3 h 6 as the source gas, argon as the diluent gas to deposit the PyC interface layer, the deposition temperature is 1000°C, and the thickness is 300nm; MTS-H 2 -Ar is the reaction source gas, CVI deposition is carried out at 1100°C and 200Pa for 40h, and the obtained low-density SiC f / SiC preform density is 2.15g / cm 3 ;

[0055] S2: Preparation of SiC f / SiC green body: 10% of sintering aid, 2% of MgO powder, 5% of silicon carbide precursor, 30% of binder, 5% of plasticizer, and 48% of nano-SiC powder are dispersed in organic dispersant, passed Mix evenly by ball milling, the ratio of ball to material is 5:1, and the time is 24h to make NITE-SiC slurry, and diffuse the NITE-SiC slurry into low-density SiC by impregnation f In the por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com