Processing device for automobile hub

A processing device and a technology for automobile wheel hubs, which are applied in the directions of grinding drive devices, grinding/polishing safety devices, and parts of grinding machine tools, etc. problem, to achieve the effect of ensuring smooth rotation, cleanliness, and circularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

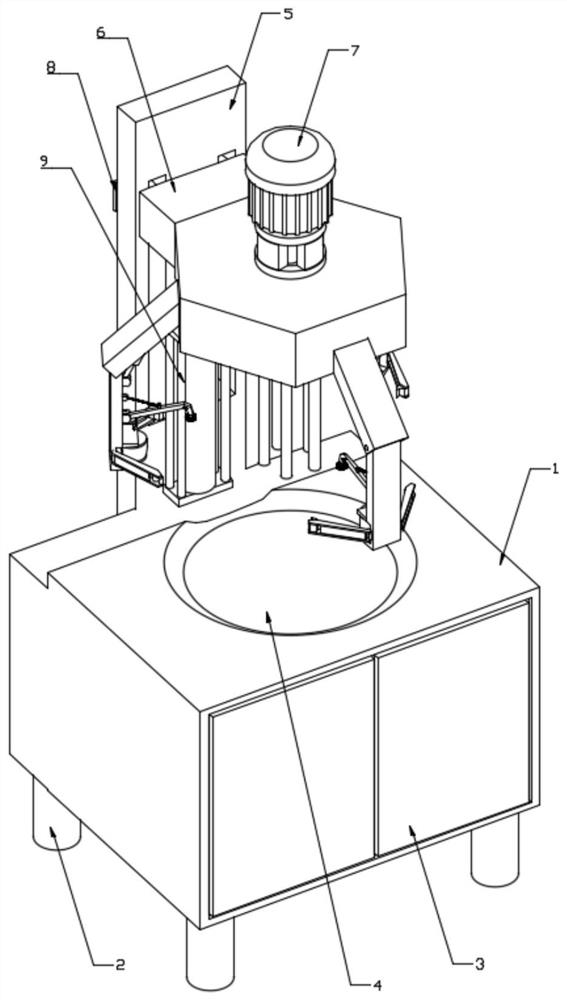

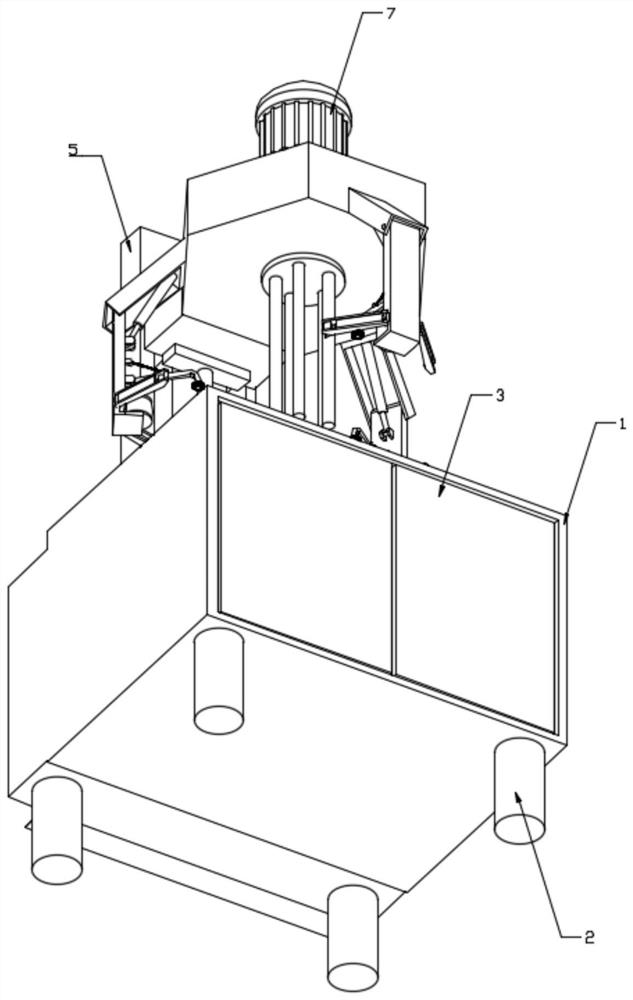

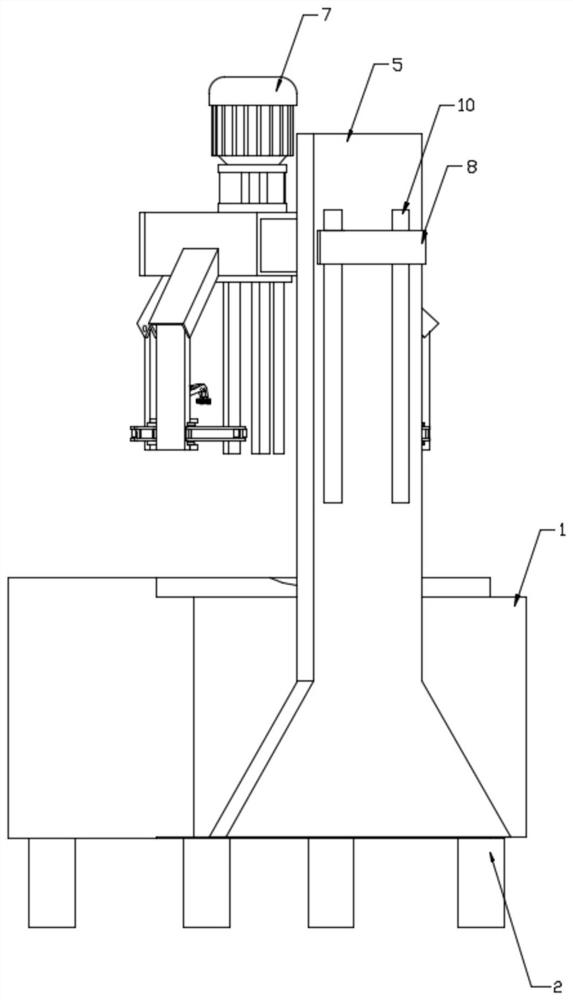

[0036] Attached below Figure 1-9 The present invention is further described with embodiment:

[0037] A processing device for an automobile hub, comprising a case body 1, legs 2 are respectively fixedly installed at the four corners of the bottom of the case body 1, the case body 1 has a box chamber, and the outside of the box room is movably connected with a A side-opening box door 3; the middle position of the top of the chassis body 1 is provided with a wheel hub placement groove 4 for easy placement of the wheel hub; the side of the chassis body 1 away from the box door 3 is fixedly installed with a mounting bracket 5; The inner side of the mounting bracket 5 is fixedly installed with a cylinder 9; the piston rod of the cylinder 9 is fixedly connected with the slide frame 6; one side of the slide frame 6 is fixedly installed with a clamping cleaning mechanism 7; The holding cleaning mechanism 7 is located directly above the hub placement groove 4;

[0038] The mounting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com