Method for detecting water resistance of paper sheet

A technology of paper and performance, which is applied in the field of testing the water resistance of paper, can solve the problems of high test requirements, no feedback of water resistance, small detection area, etc., and achieve the effect of large detection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

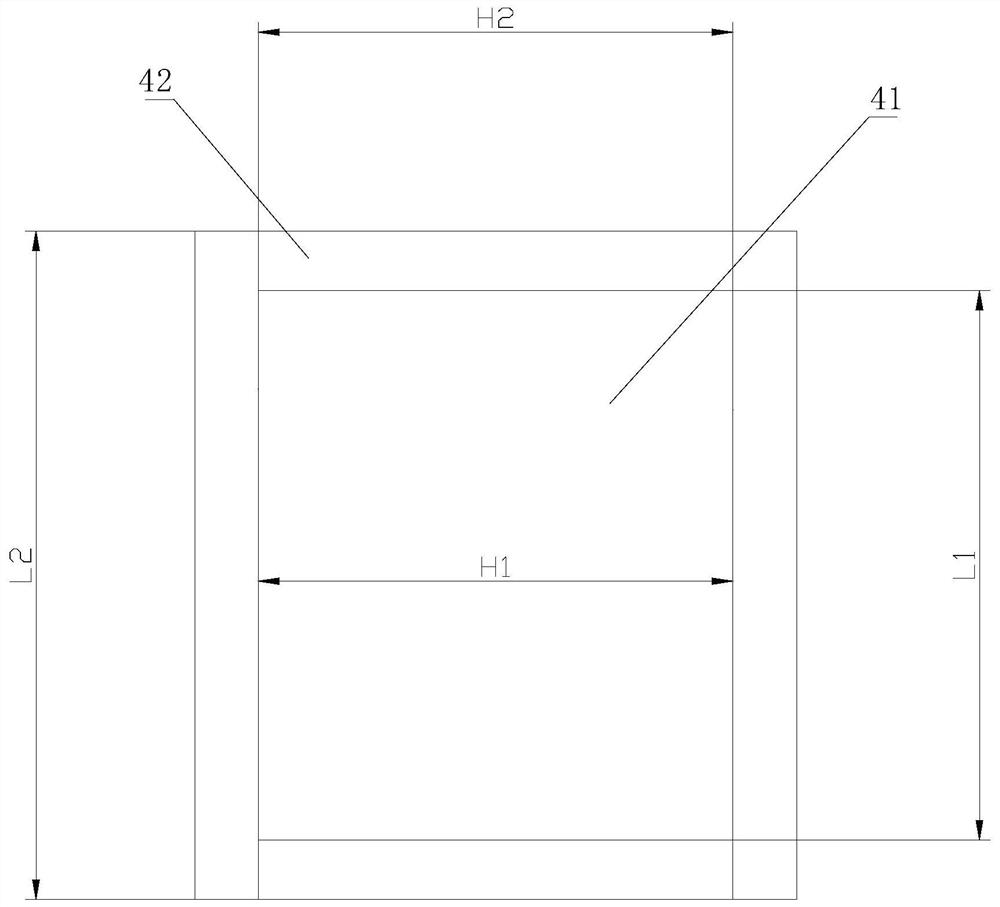

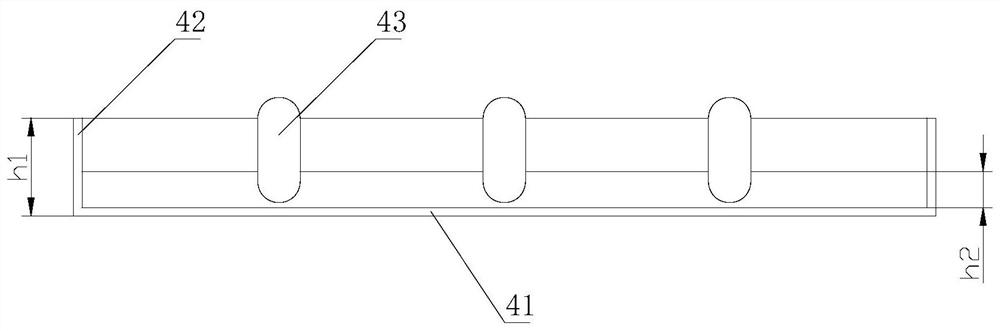

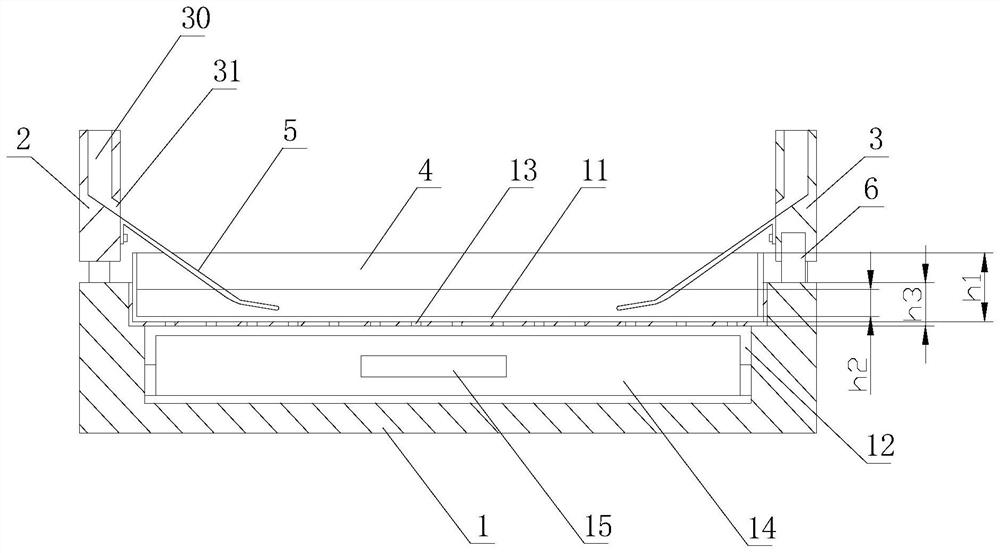

[0024] Such as figure 1 , figure 2 , image 3 As shown, a method for detecting the water resistance of a paper sheet is based on the detection device. The detection device includes a base 1, a left vertical rod 2 and a right vertical rod 3, and the left vertical rod 2 is arranged at one end of the base 1, so that Described right upright 3 is arranged on the other end of base 1, and described base 1 is provided with the groove 11 of placing paper, and described groove 11 is arranged between left upright 2 and right upright 3, in groove The base 1 below the 11 is provided with a cavity 12, the groove 11 is provided with a drainage hole 13 for judging whether the paper page has a penetration point, and the left vertical rod 2 and / or the right vertical rod 3 are provided with Vertical through hole 30, described left vertical pole 2 and / or right vertical pole 3 are provided with the outlet hole 31 that communicates with vertical through hole 30, described method comprises the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com