Belt crack detection method based on image recognition

A detection method and image recognition technology, applied in measurement devices, optical testing flaws/defects, instruments, etc., can solve problems such as inability to guarantee accuracy, reduce the service life of the carrier belt, and inability to quickly locate the location of the tearing part, to avoid The effect of false alarms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

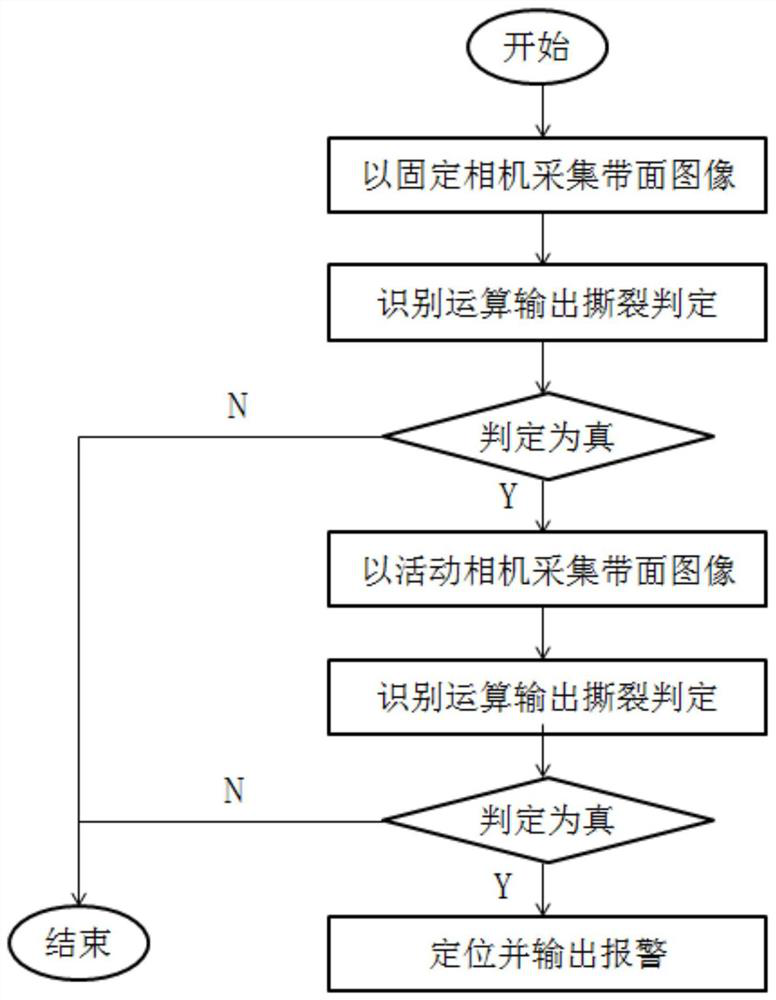

[0032] A belt crack detection method based on image recognition, comprising:

[0033] Step 1: Operate the first camera to collect the belt surface image of the belt surface at a frequency of 1 per second, the first camera is a fixed camera and is vertically fixed directly above the middle section of the belt to be detected in the circular transmission;

[0034] Step 2: Transmit the surface image obtained by the first camera to the background system for recognition calculation, and output the tear recognition judgment; if the tear recognition judgment is true, then jump to step 3;

[0035] Step 3: Collect the belt surface image of the belt surface with the second camera, the second camera is installed on the inspection robot; the inspection robot is installed on the slide rail and reciprocates along the extension direction of the slide rail; the slide rail Parallel to directly above the endless drive belt.

[0036] Step 4: Transmit the surface image obtained by the second came...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com